【International Papers】Interrelationships Between Topology and Wettability of Nanostructured Composite Wide Bandgap Metal Oxide Films Prepared by Spray Pyrolysis

日期:2025-03-25阅读:609

Researchers from the Technical University of Moldova have published a dissertation titled "Interrelationships Between Topology and Wettability of Nanostructured Composite Wide Bandgap Metal Oxide Films Prepared by Spray Pyrolysis" in Applied Sciences.

Abstract

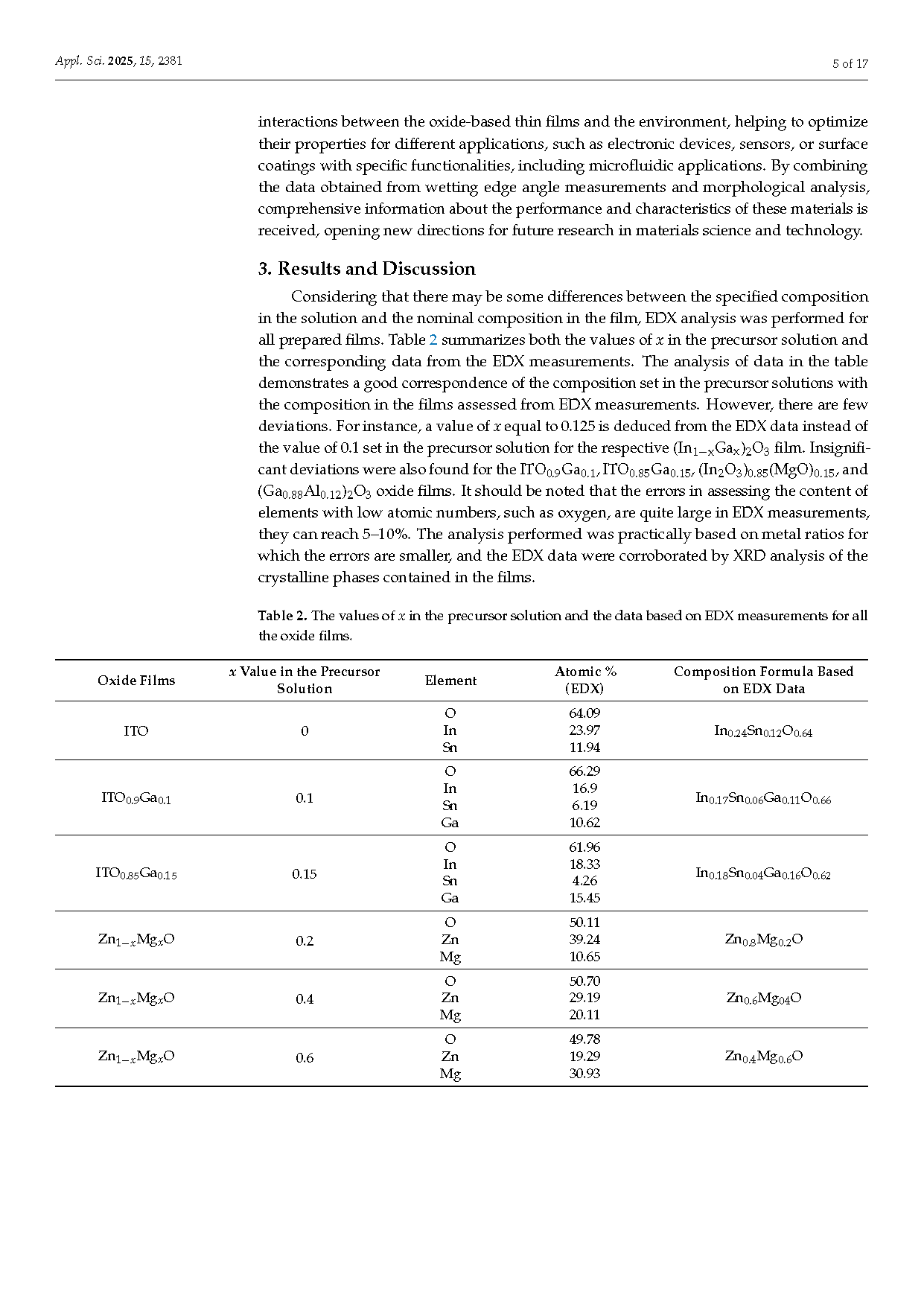

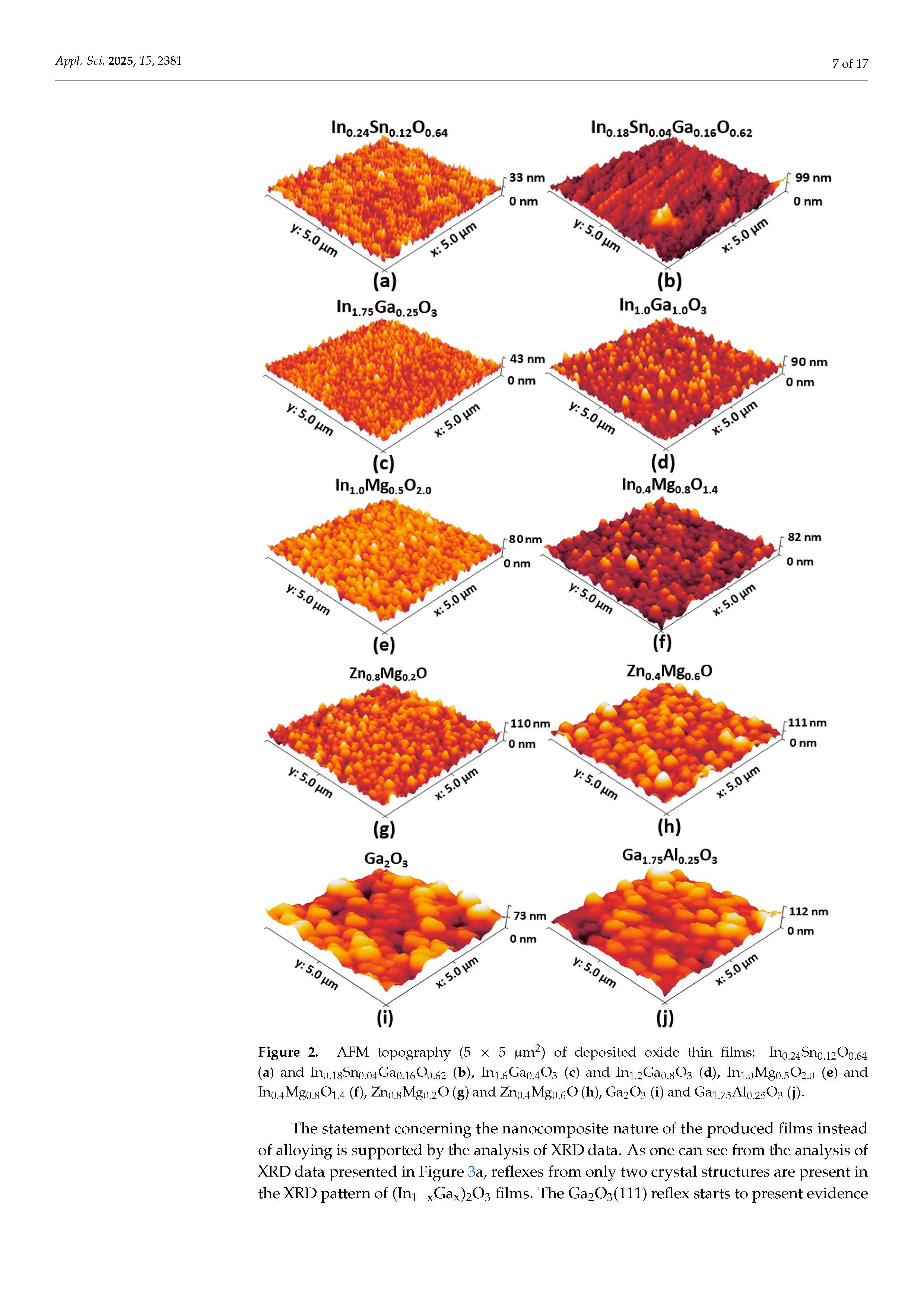

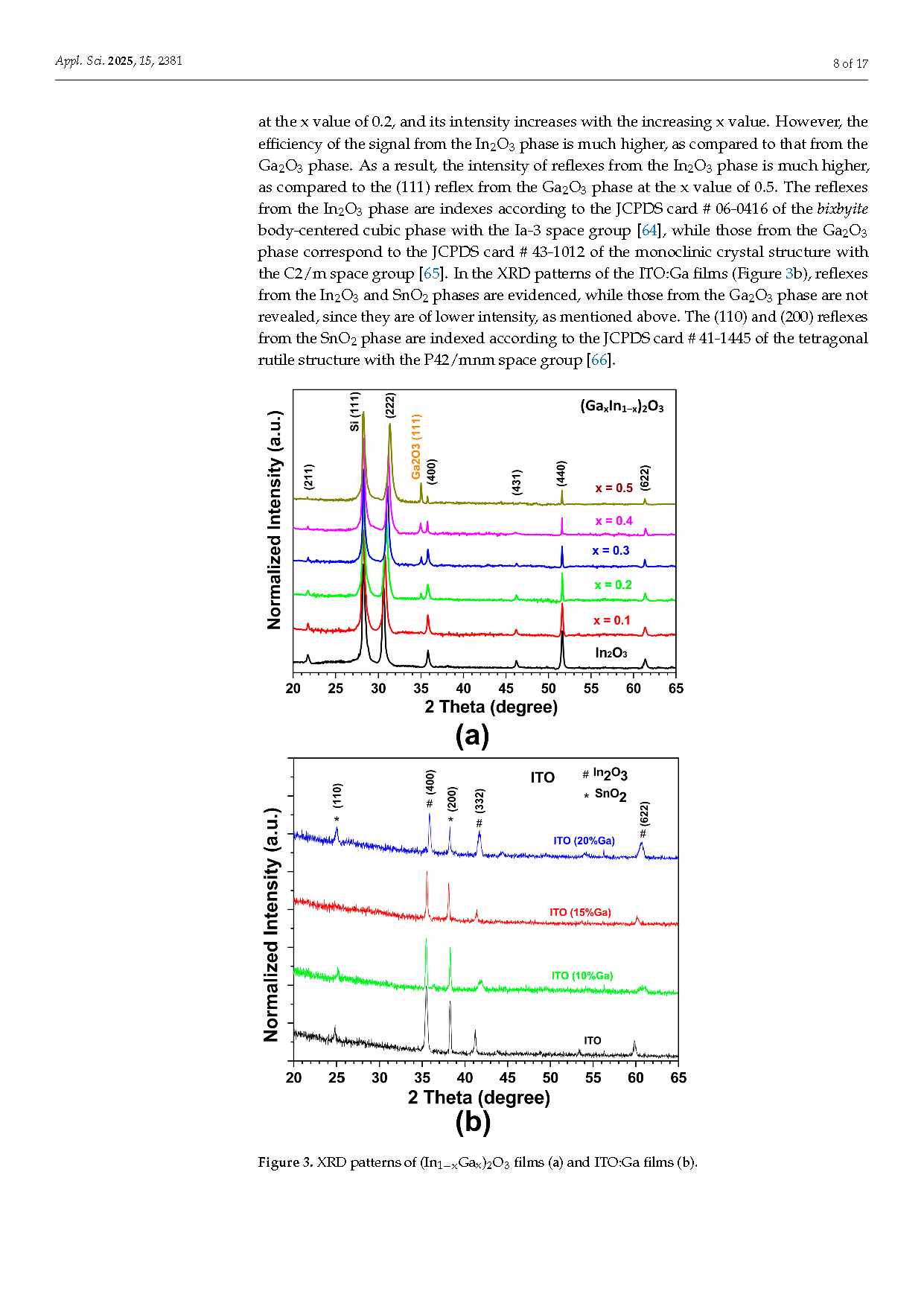

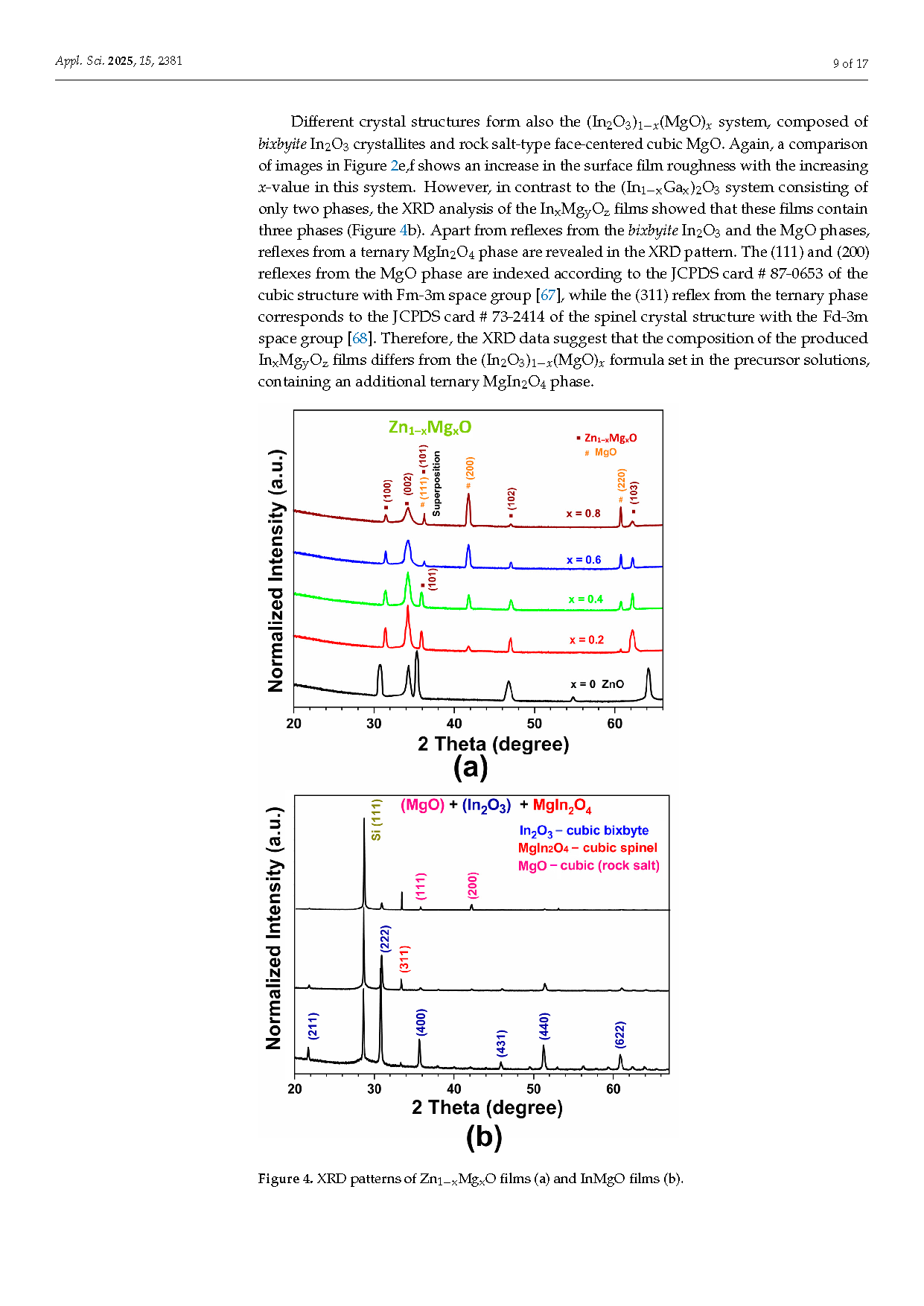

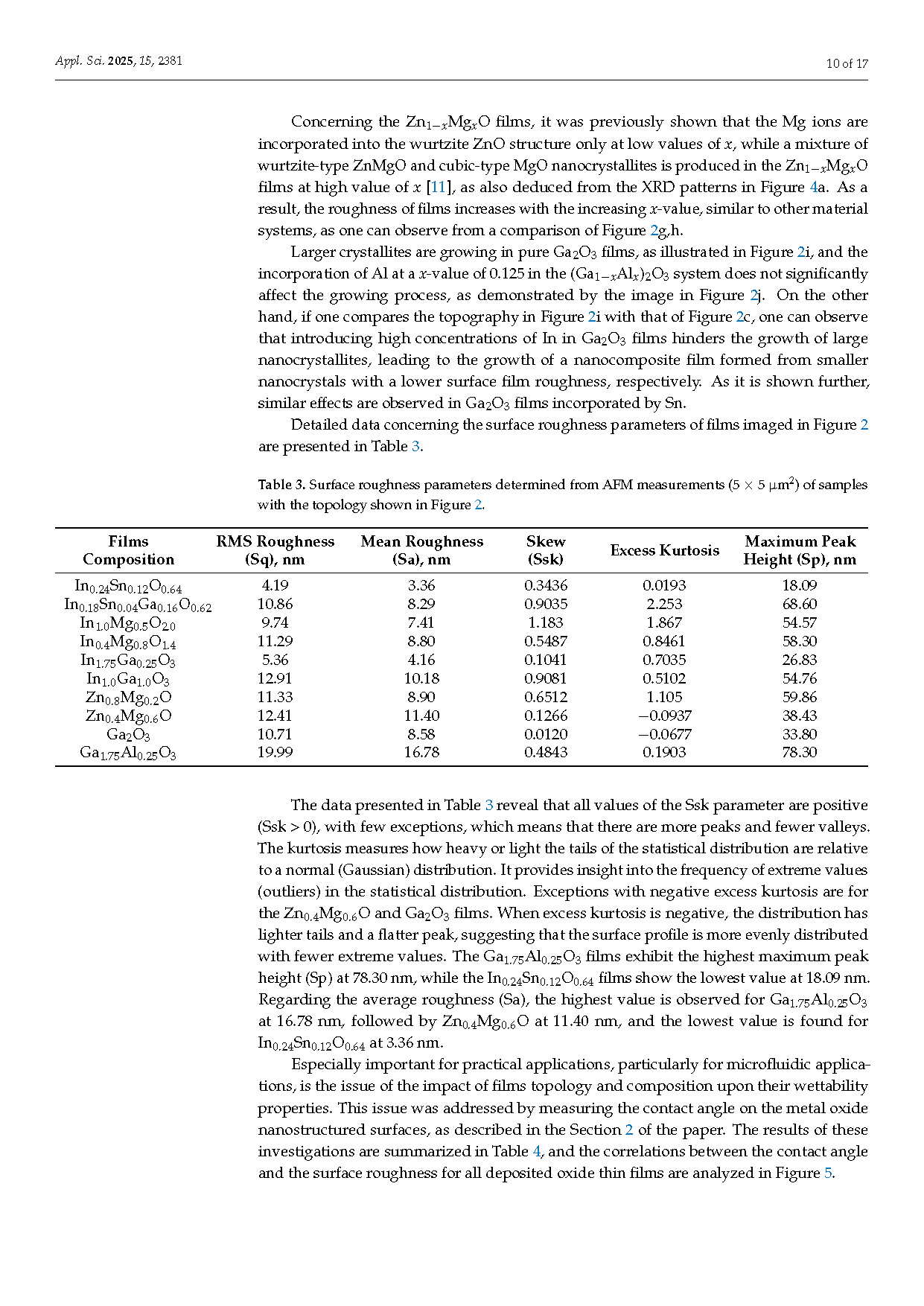

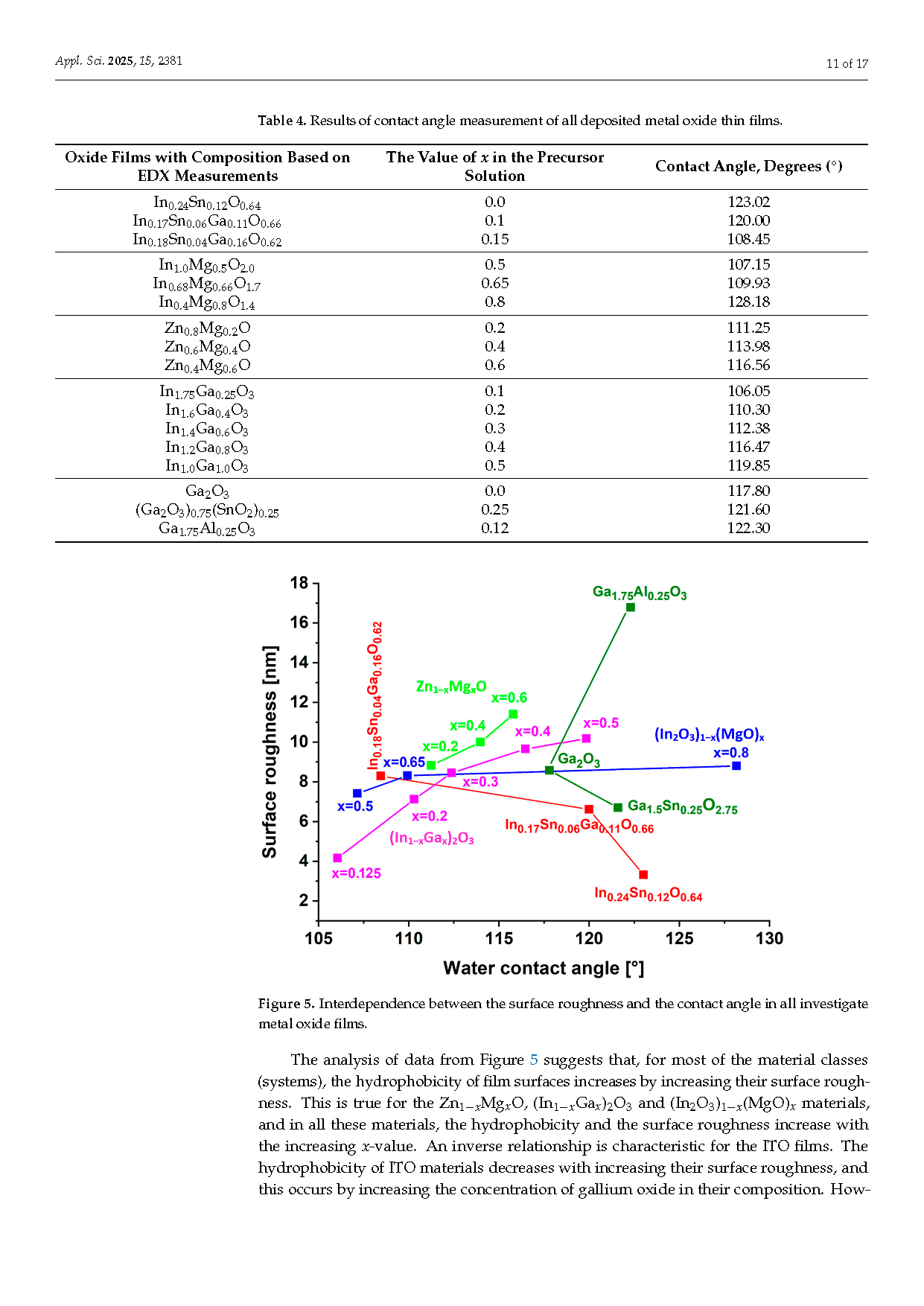

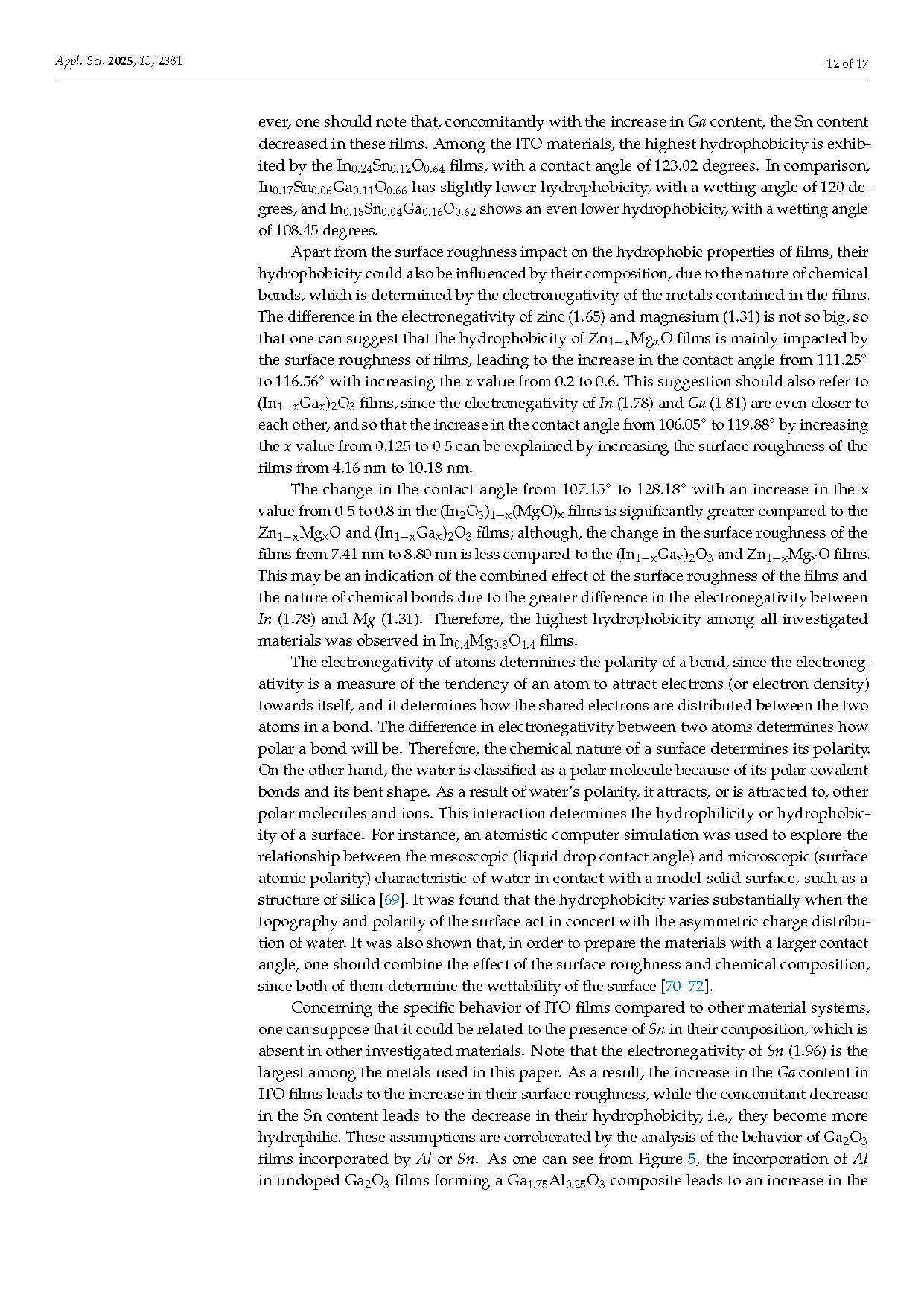

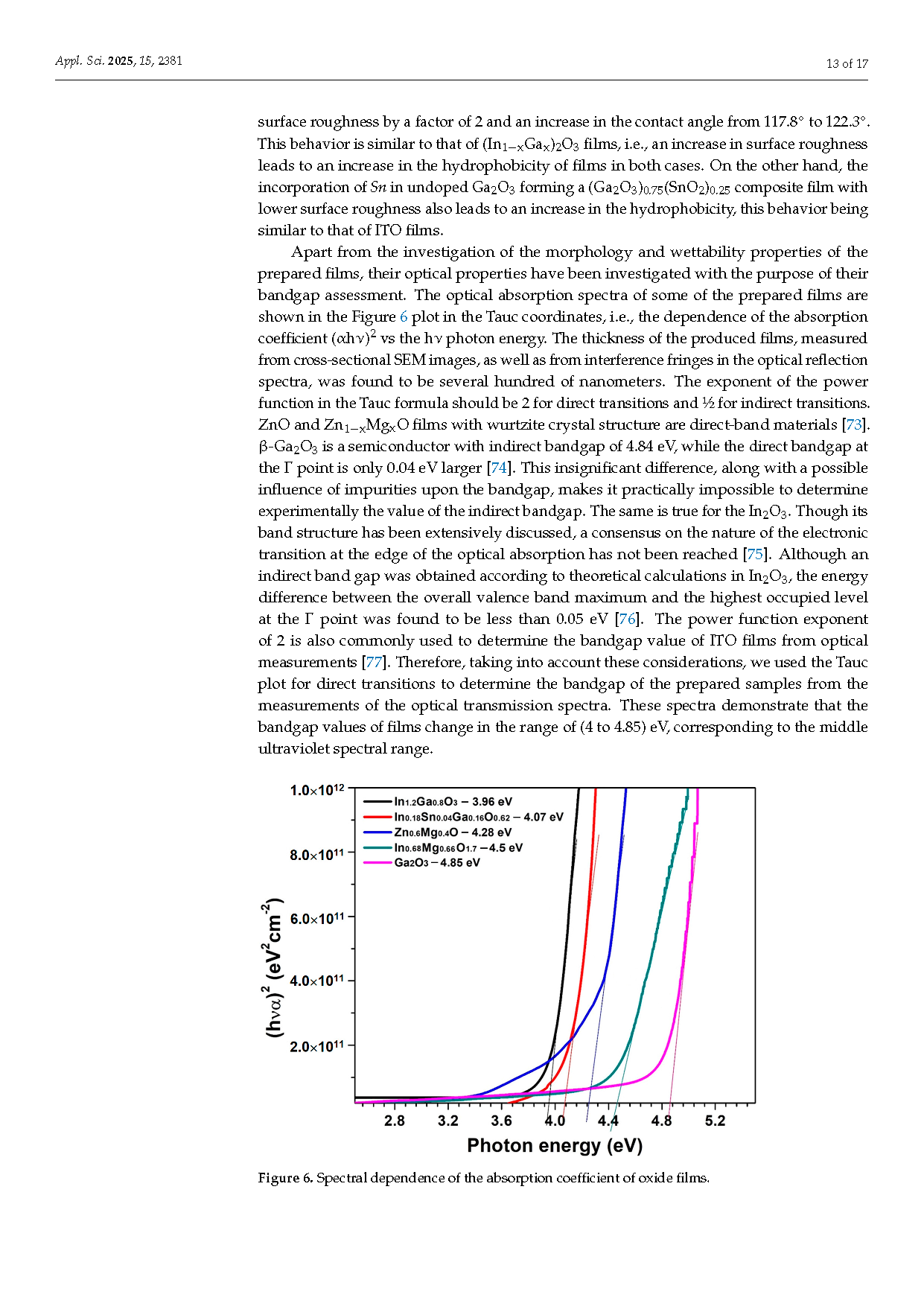

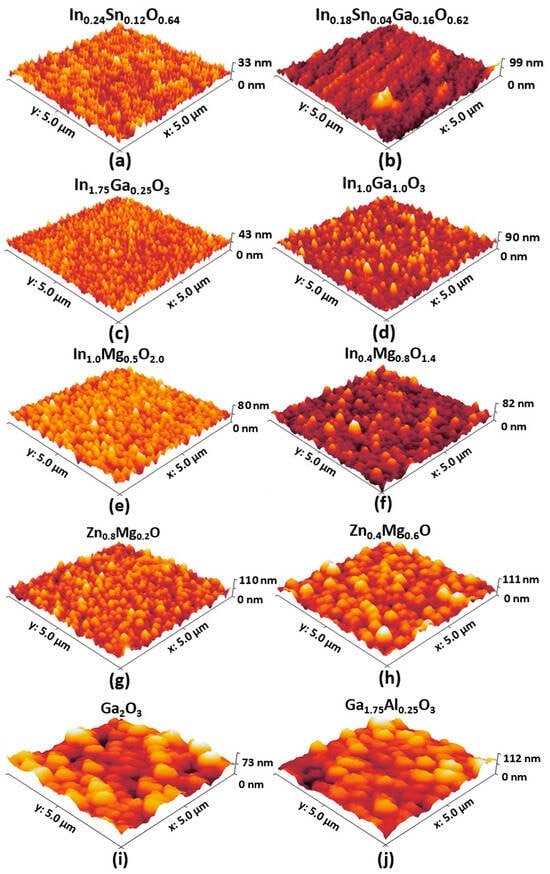

The interrelationships between the topological features, such as surface roughness deduced from atomic force microscopy (AFM), and wettability properties expressed by the contact angle of a water droplet on the surface of nanostructured wide bandgap oxide films prepared by spray pyrolysis are investigated for a wide range of compositions. A direct relationship between the surface roughness and the value of the contact angle was found for nanocomposite (In2O3)1−x(MgO)x, (In1−xGax)2O3, and Zn1−xMgxO films, for which both the surface roughness and the contact angle increase with the increasing x-value. On the other hand, in ITO films doped with Ga, it was found that the surface roughness increases by increasing the Ga doping, while the contact angle decreases. Both the surface roughness and the contact angle proved to increase in Ga2O3 films when they were alloyed with Al2O3, similar to other nanocomposite films. An inverse relationship was revealed for a nanocomposite formed from Ga2O3 and SnO2. The contact angle for a (Ga2O3)0.75(SnO2)0.25 film was larger as compared to that of the Ga2O3 film, while the surface roughness was lower, similar to ITO films. The highest value of the contact angle equal to 128° was found for a (In2O3)1−x(MgO)x film with an x-value of 0.8, and the largest RMS roughness of 20 nm was showed by a Ga1.75Al0.25O3 film. The optical properties of the prepared films were also analyzed from optical absorption spectroscopy, demonstrating their bandgap variation in the range of (4 to 4.85) eV, corresponding to the middle ultraviolet spectral range.

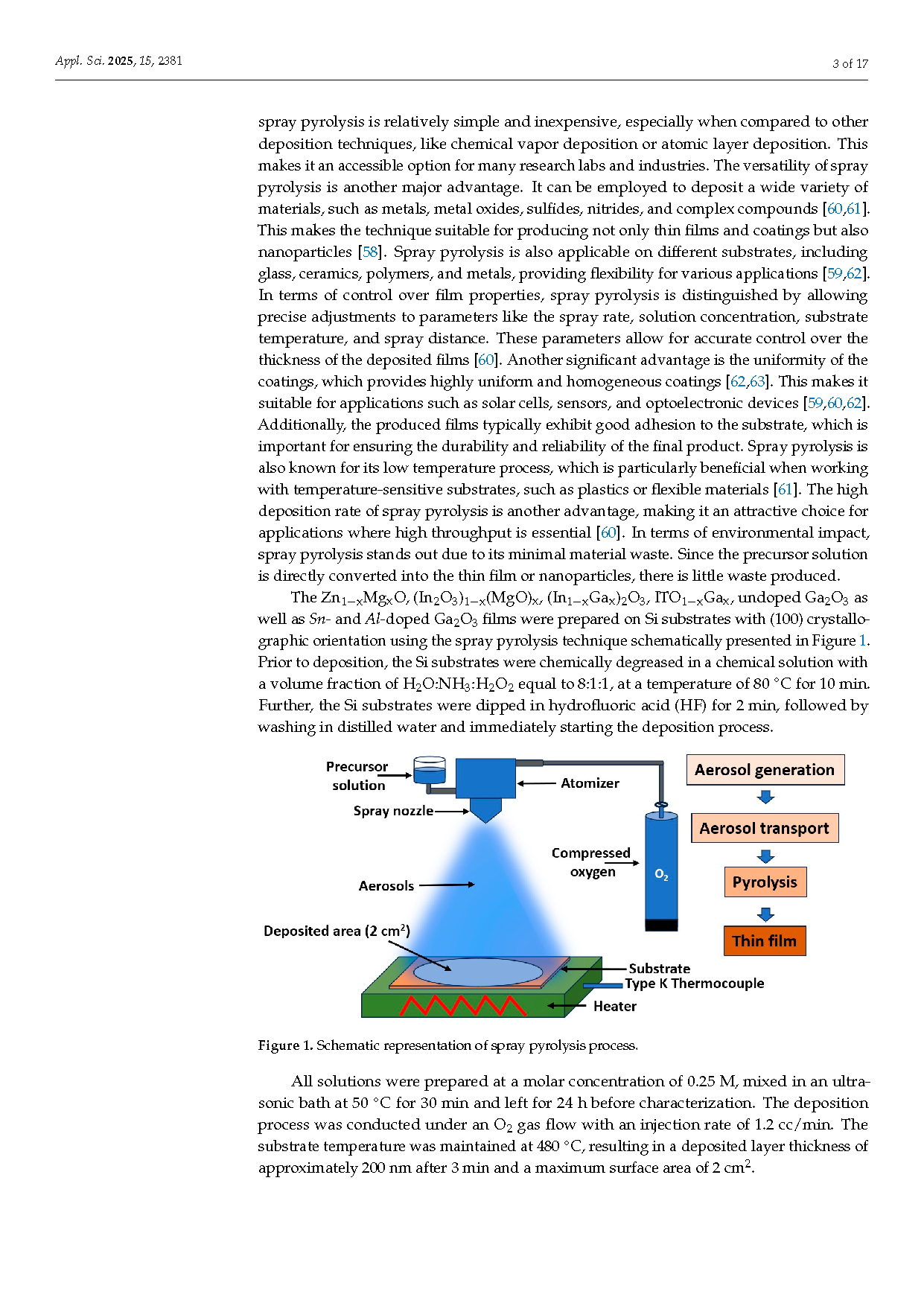

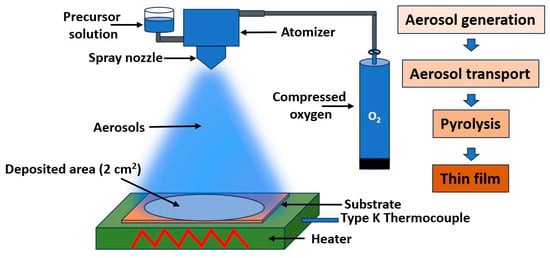

Figure 1. Schematic representation of spray pyrolysis process.

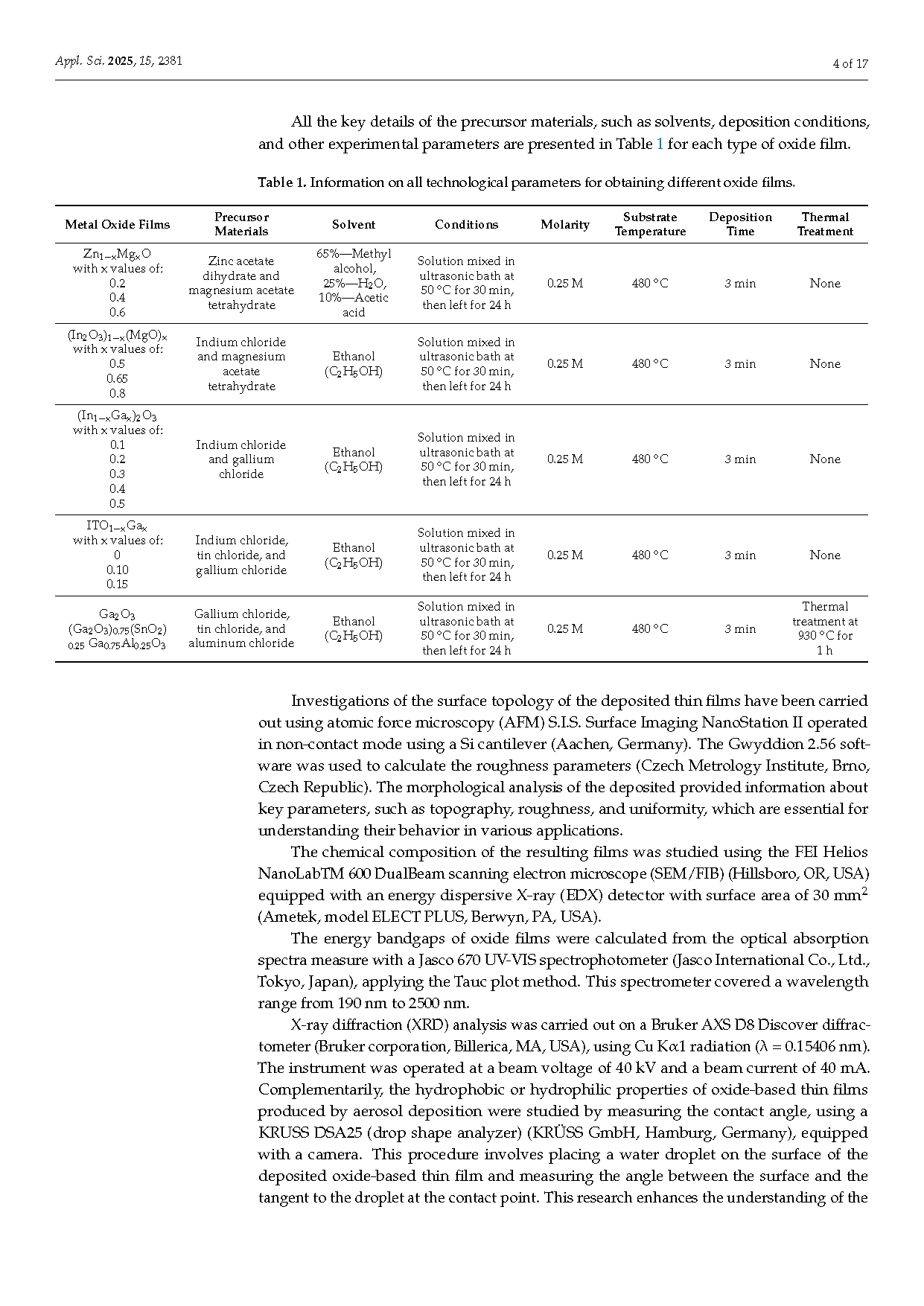

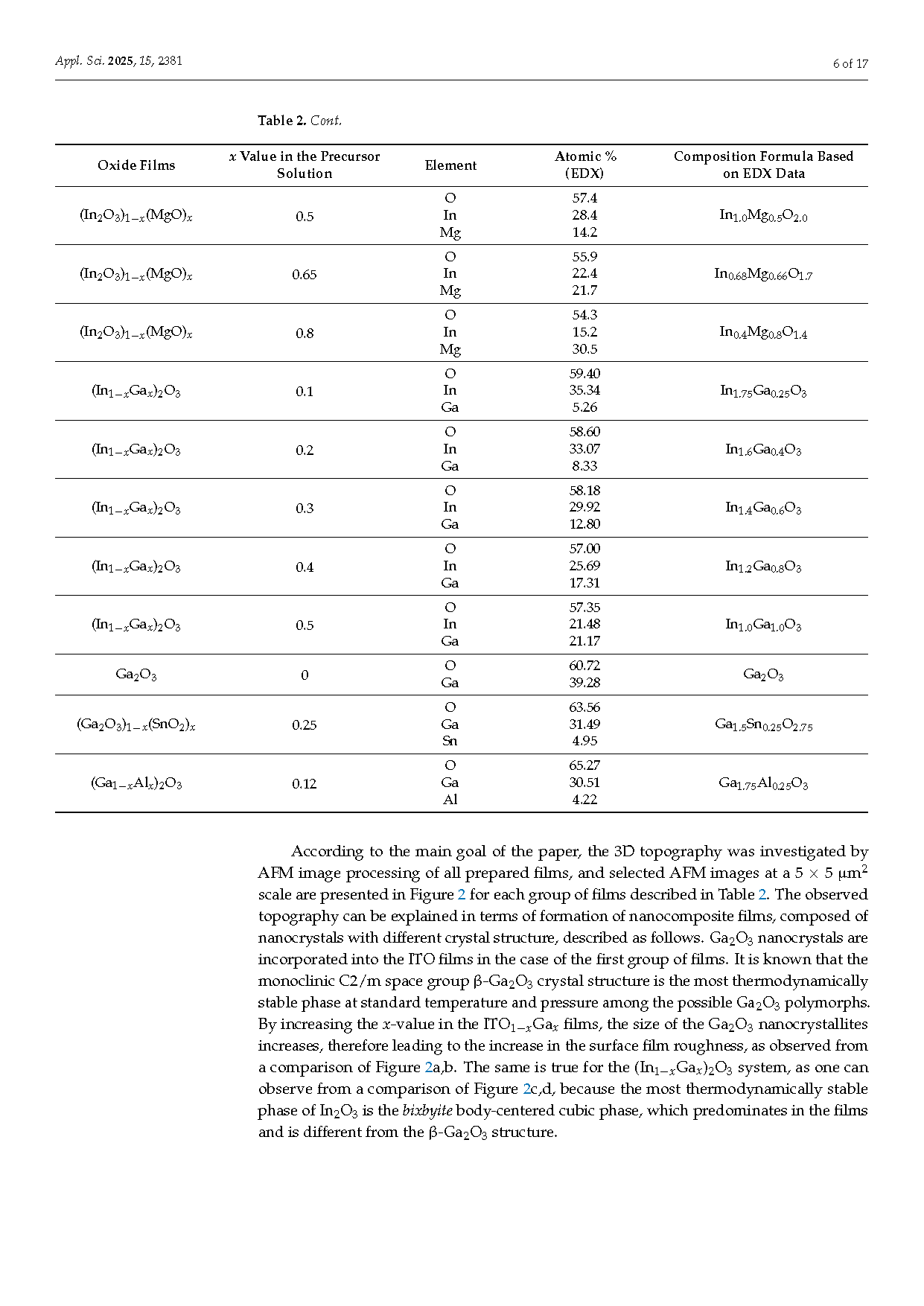

Figure 2. AFM topography (5 × 5 μm2) of deposited oxide thin films: In0.24Sn0.12O0.64 (a) and In0.18Sn0.04Ga0.16O0.62 (b), In1.6Ga0.4O3 (c) and In1.2Ga0.8O3 (d), In1.0Mg0.5O2.0 (e) and In0.4Mg0.8O1.4 (f), Zn0.8Mg0.2O (g) and Zn0.4Mg0.6O (h), Ga2O3 (i) and Ga1.75Al0.25O3 (j).

DOI:

doi.org/10.3390/app15052381