【Domestic Papers】Researchers Led by Academician Deren Yang from the Zhejiang University——An effective KOH solution etching method in defect characterization of (100) β-Ga₂O₃

日期:2025-03-25阅读:640

Researchers from the Zhejiang University have published a dissertation titled " An effective KOH solution etching method in defect characterization of (100) β-Ga2O3" in Materials Science in Semiconductor Processing.

Project Support

This work was supported by the “Pioneer” and “Leading Goose” R&D Program of Zhejiang (2023C01193), the National Natural Science Foundation of China (52202150, 22205203, and 62204218), Fundamental Research Funds for the Central Universities (226-2022-00200 and 226-2022-00250), the National Postdoctoral Program for Innovative Talents (BX20220264), the National Program for Support of Topnotch Young Professionals, and the Leading Innovative and Entrepreneur Team Introduction Program of Hangzhou (TD2022012).

Background

β-Ga2O3, with its ultra-wide bandgap and high breakdown electric field, is a promising material for high-power electronics and optoelectronics. However, its performance is significantly affected by defects such as dislocations, strain-induced defects, and voids. Traditional hot phosphoric acid (H₃PO₄) etching has limitations in distinguishing different defect types. This study investigates a KOH solution etching method for enhanced selectivity and improved defect characterization on (100) β-Ga2O3 substrates.

Abstract

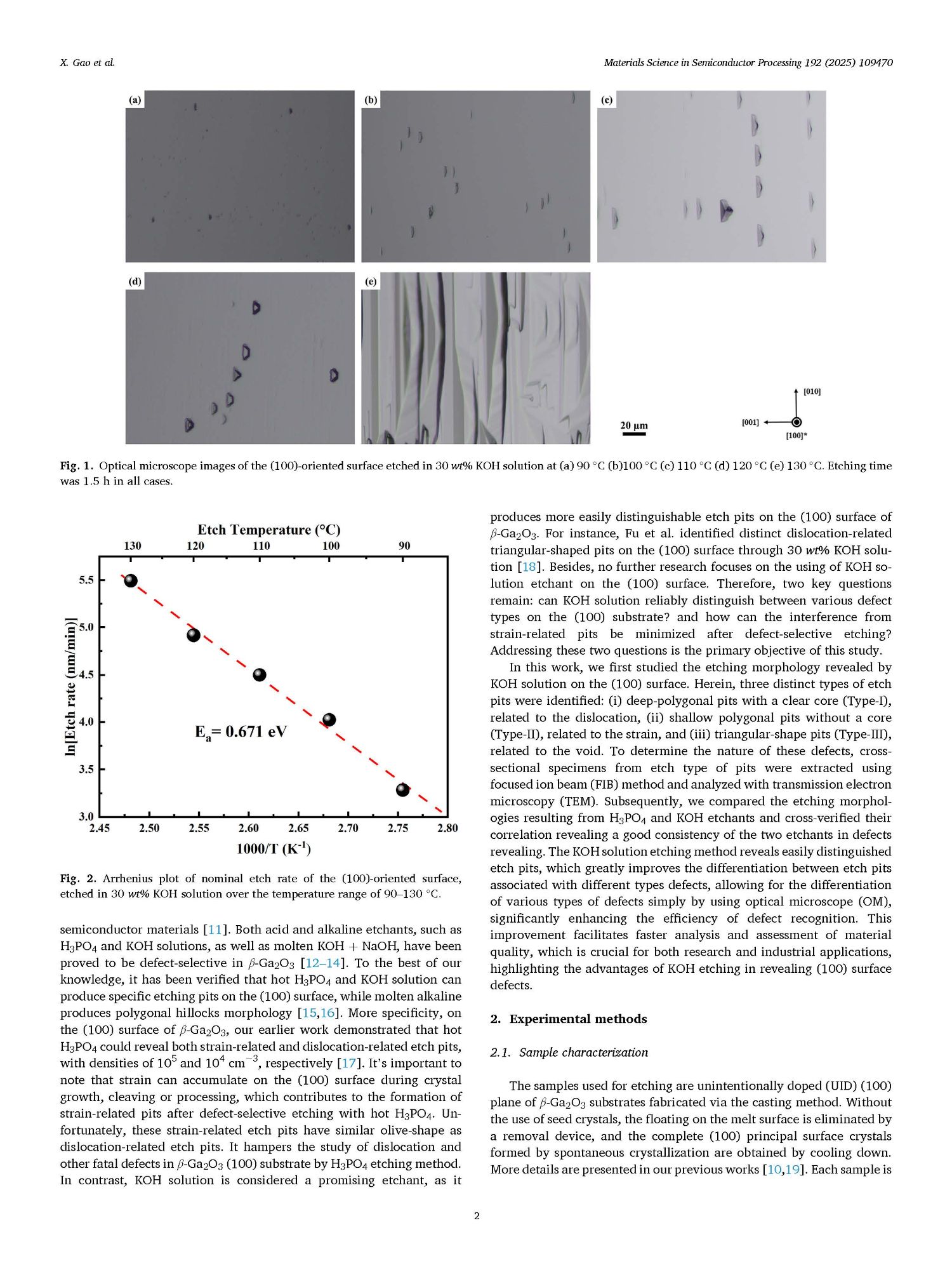

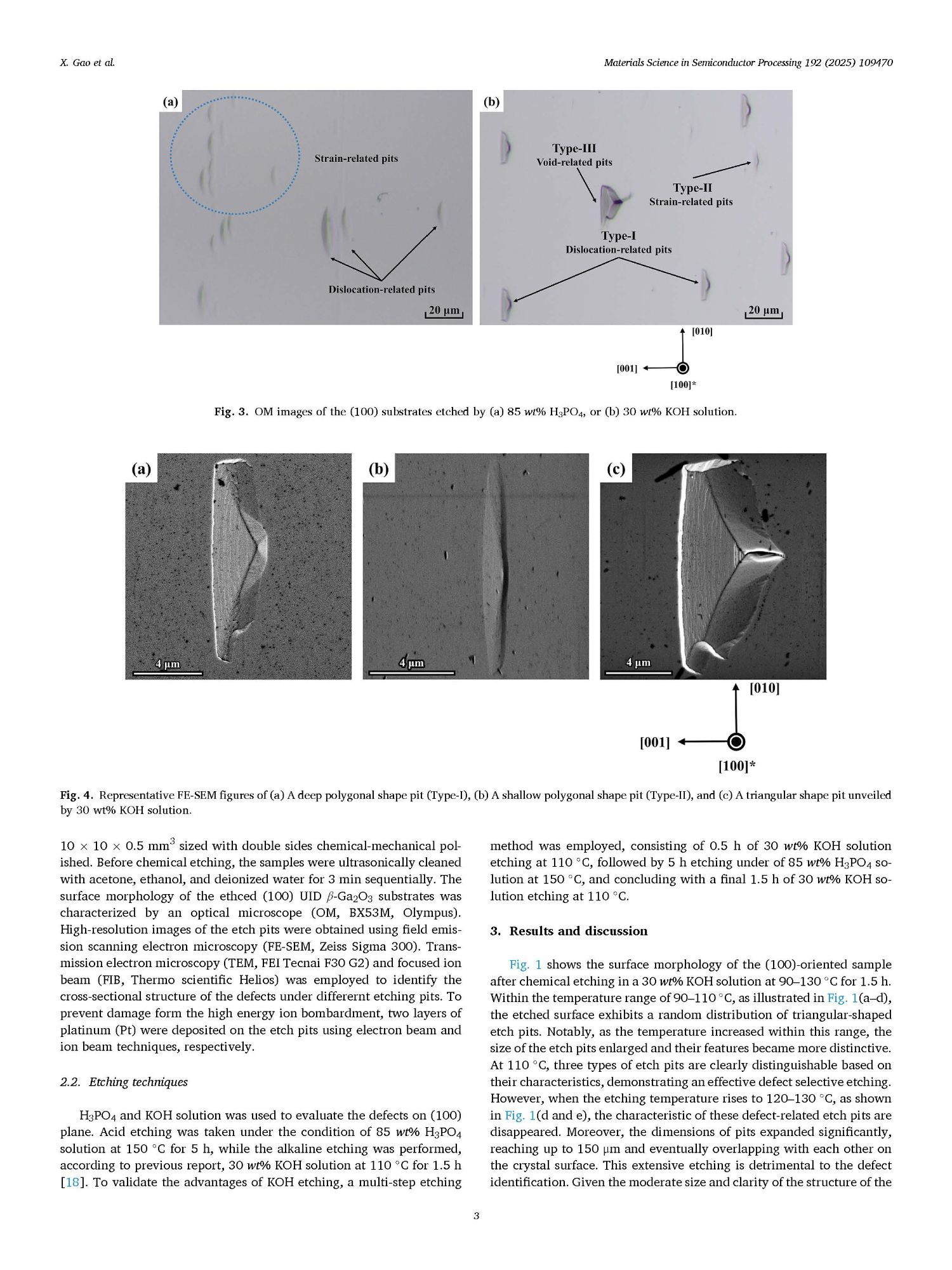

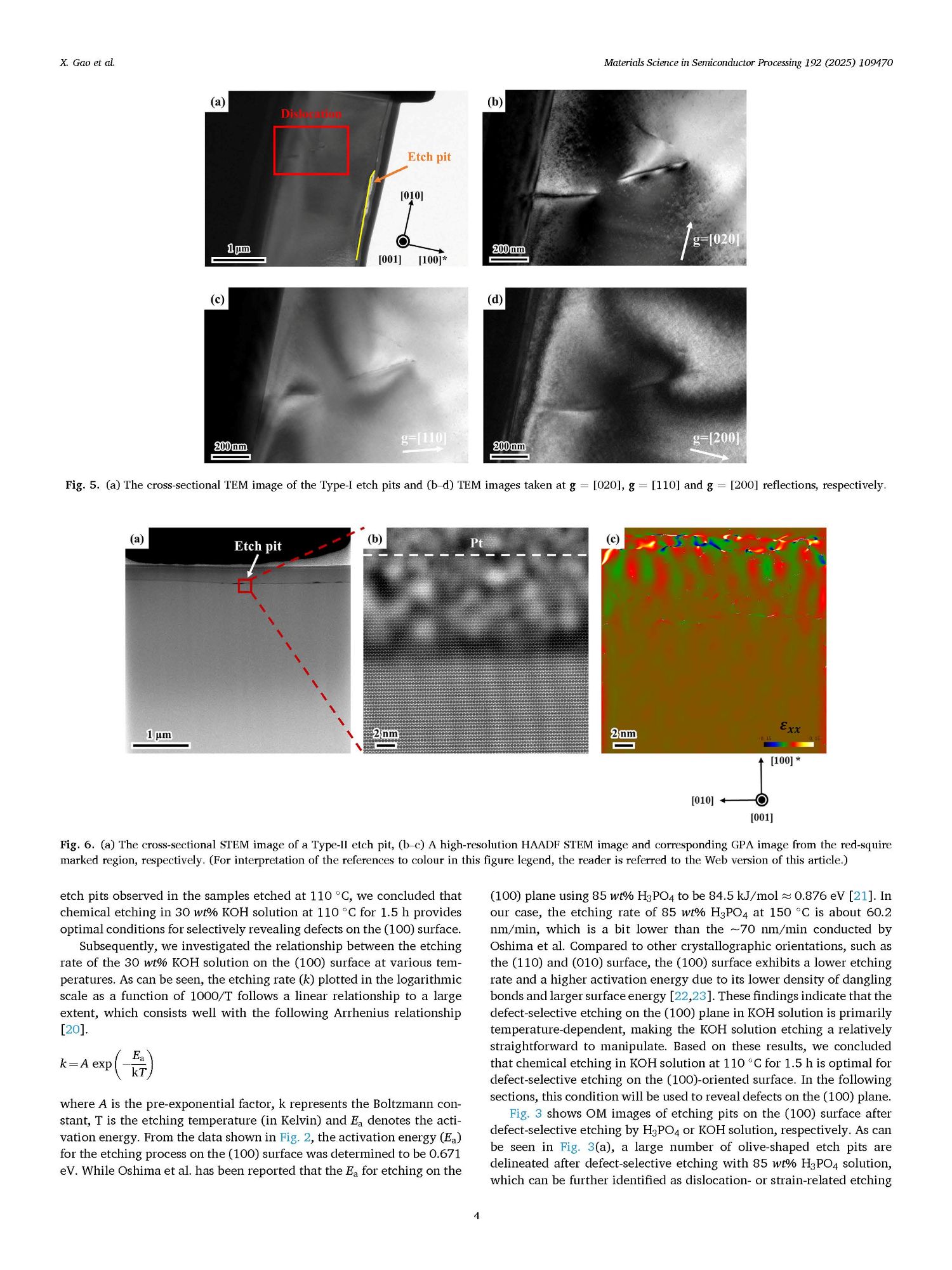

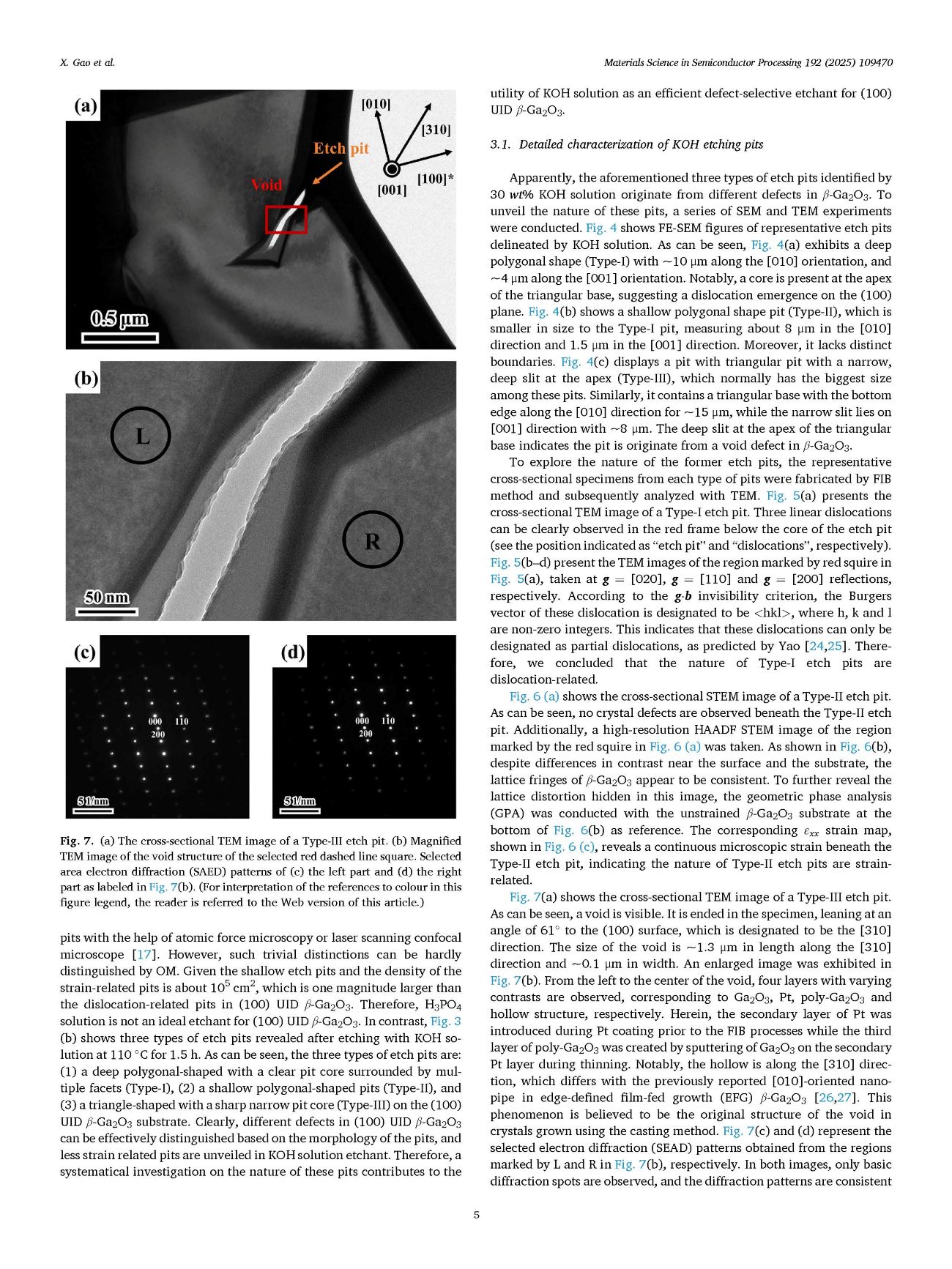

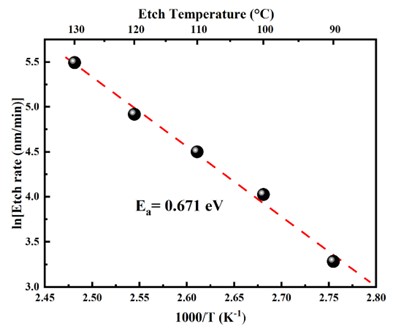

Chemical etching offers a simple and efficient method for revealing defects in semiconductor materials, highlighting the importance of etchants selection. While H3PO4 is commonly used for defect-selective etching on the (100) surface of β-Ga2O3, its inability to effectively distinguish between different types of defects necessitates the use of alternative etchants, such as alkali solutions. In this work, we investigated the kinetics of defect-selective etching using 30 wt% KOH solution on the (100) surface of β-Ga2O3, determining an activation energy (Ea) of 0.671 eV and establishing an optimal defect-selective etching condition of 110 °C for 1.5 h. Three types of etch pits were observed by Optical Microscope (OM), and subsequently identified as dislocation-, strain- and void-related pits using transmission electron microscopy (TEM) combined with focused ion beam (FIB). Compared to H3PO4, KOH etching enables differentiation of these types defects on (100) surface of β-Ga2O3 directly by OM, offering a more effective and accurate approach for defect revelation. This research presents a novel and efficient method for defects revealing on the (100) plane, highlighting its potential in defects characterization in β-Ga2O3.

Conclusion

The 30 wt% KOH solution at 110°C for 1.5 h provides an efficient and selective etching method for defect characterization in (100) β-Ga2O3. Compared to H₃PO₄ etching, KOH etching enables clearer and more precise defect identification, making it a valuable technique for industrial inspection and quality control of β-Ga2O3 crystals.

Fig. 1. Optical microscope images of the (100)-oriented surface etched in 30 wt% KOH solution at (a) 90 °C (b)100 °C (c) 110 °C (d) 120 °C (e) 130 °C. Etching time was 1.5 h in all cases.

Fig. 2. Arrhenius plot of nominal etch rate of the (100)-oriented surface, etched in 30 wt% KOH solution over the temperature range of 90–130 °C.

DOI:

doi.org/10.1016/j.mssp.2025.109470