【Member Intro】Guizhou University-Engineering Research Center of Reliability of Semiconductor Power Devices of Ministry of Education —— Regular Member

日期:2025-05-20阅读:1203

I. Introduction

After more than 120 years of development and construction, Guizhou University has successively become a "Project 211" university, a "Double First-Class" university, and a "Ministry-Provincial Joint Construction" university by the Ministry of Education and the People's Government of Guizhou Province.

The discipline of "Electronic Science" at Guizhou University originated from the "Specialization of Physics in Electronics" in 1961 and the "Specialization of Physics in Semiconductors" in 1962. In 1972, the two majors of "Semiconductor" and "Electronic Technology" began to admit students, and the names of the majors changed several times. In 1998, the names of the two undergraduate majors were determined as "Electricity Subscience and Technology" and "Electronic Information Science and Technology". "Microelectronics and Solid State Electronics" obtained a master's degree authorization in 1997 and a second level discipline doctoral degree authorization in 2003, "Circuit and System" was granted a master's degree authorization in 2000, and "Electronic Science and Technology" was granted a first-level degree authorization point and postdoctoral mobile station in 2011. "Electronic Information" will be granted a doctoral degree authorization in this major in 2024. After more than 60 years of development, the "Electronic Science" discipline at Guizhou University has become an important base for cultivating high-end talents in the electronic information and big data industries in Guizhou.

Engineering Research Center of Reliability of Semiconductor Power Devices of Ministry of Education (hereinafter referred to as the "Engineering Research Center") is based on the "Electronic Science" discipline of Guizhou University and was approved for construction by the Ministry of Education in 2014. The Engineering Research Center is positioned to tackle key technologies of high-quality electronic components and build an open platform for industry-education-research engineering research and application based in Guizhou and radiating throughout the country. Basic research and industrial promotion will be carried out around three characteristic research directions: power devices and power integrated circuits, testing and application technology, and electronic materials and processes. The engineering center has a laboratory area of 5,216.7 square meters and 91 sets of equipment worth over 300,000 yuan, with a total equipment value of over 110 million yuan. In the past five years, the related technological achievements of the engineering center have generated more than 1 billion yuan in economic value through promotion and application.

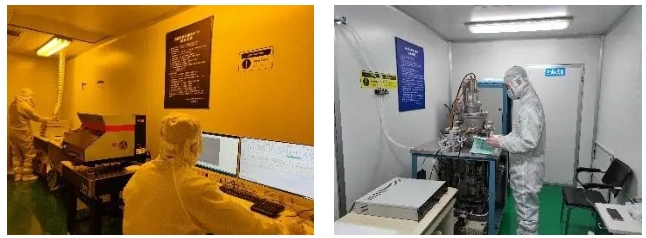

Some of the office scenarios of the Engineering center are as follows:

Figure 1 Engineering Research Center office building

Figure 2 office scene of the Engineering Research Center

Figure 3 maskless lithography Figure 4 magnetron sputtering

II. Achievements

· Research Achievements

1. Academic Papers

(1)Liuhan Zhou, Lai Yang, Fashun Yang, Xu Wang, and Kui Annealing effectson post-deposition β-Ga2O3 thin film prepared through radiofrequency magnetron sputtering, International Journal of Nanotechnology, Vol.21, No.6, 2024, pp.437-456.

(2)Wang Xu, Ran Jingyang, Yang Lai, Yang Fashun, Ma Experimentally study on the effect of RIE etching power on etching rate of β-Ga2O3 thin film, 2022 International Symposium on Semiconductor Manufacturing (ISSM). 2022-12-12 to 2022-12-13, 2022, Tokyo, Japan, pp. 1-4.

(3) Zhong Qiongli, Wang Xu, Ma Kui, Yang Fashun. Study on the effect of Al doping on the optical properties of β-Ga2O3 thin films, Journal of Synthetic Crystals, Vol.53, No.8, 2024, pp.1352-1360

(4) Zeng Xiangyu, Ma Kui, Yang Fashun. Dry etching by inductively coupled plasma based on SF6/Ar β-Ga2O3 thin films, Semiconductor Technology, Vol.49, No.7, 2024, pp.624-628

(5) Huang Mengru, Lu Linhong, Guo Fengjie, Ma Kui, Yang Fashun. Ar plasma dry etching of Ti/Ni/Ag thin films based on ICP, Semiconductor Technology, Vol.49, No.10, 2024, pp.893-898

(6) Yang Lai, Yang Fashun, Xiong Qian, Ma Kui. The effect of magnetron sputtering oxygen-argon volumetric flow ratio on β-Ga2O3 thin films. Micronanoelectronics Technology, Vol.60, No.3, 2023, pp. 448-453.

(7) Yang Lai, Gao Cancan, Yang Fashun, Ma Kui. The effect of post-annealing time on the preparation of β-Ga2O3 thin film materials by magnetron sputtering. Journal of Atomic and Molecular Physics, Vol.39, No.5, 2022, pp. 053002-1~6.

(8) Ran Jingyang, Gao Cancan, Ma Kui, Yang Fashun. Magnetron sputtering power on the properties of β-Ga2O3 thin films, Journal of Atomic and Molecular Physics, Vol.39, No.4, 2022, pp.043001-1-043001-5.

(9) Gao Cancan, Ji Kaidi, Ma Kui, Yang Fashun. Heating temperature and post-annealing temperature of magnetron sputtering substrate pair effects on the preparation of β-Ga2O3 thin film materials, Journal of Synthetic Crystals, Vol.50, No.02, 2021, pp. 296-301+309

(10) Ji Kaidi, Gao Cancan, Yang Fashun, Xiong Qian, Ma Kui. Preparation by magnetron sputtering in post-annealed atmosphere effects of β-Ga2O3 thin film materials. Journal of Synthetic Crystals, Vol.50, No.6, 2021, pp. 1056-1061.

2. Patent

(1) Ma Kui, Yang Fashun, Guo Fengjie, Lu Linhong, Ran Jingyang, Huang Mengru, Shen Ju. A method for preparing thin films on non-flat surfaces based on substrate tilt rotation, 2024-05-21, China, CN202410633954.X.

(2) Ma Kui, Yang Fashun, Lu Linhong, Zhou Liuhan, Huang Mengru, Guo Fengjie. A Process Method for Enhancing the Thermal Conductivity of Gallium Oxide Materials, 2023-11-29, China, 2023116152840.

(3) Ma Kui, Yang Fashun, Xiong Qian, Wang Xu, Yang Lai. Preparation method and semiconductor materials for selective doping of silicon in Aluminum Nitride films, 2022-8-1, China, 202210896755.9.

(4) Ma Kui, Yang Fashun, Yang Lai, Kai Di, Gao Cancan. An Implementation Method for Doping Metal Atoms in Gallium Oxide Materials, 2021-12-01, China, CN202111453562.8.

3. Science and Technology Awards

(1) Second Prize of Science and Technology Progress of Guizhou Province in 2023, Research and Application of Key Technologies for High-Performance Monolithic Integrated Converters for Aerospace Vehicles, completed by Guizhou Zhenhua Fengguang Semiconductor Co., Ltd. and Guizhou University, completed by Li Xue, Ma Kui, Duan Fang, Yuan Xinglin, Gong Hong, Tan Yong, Yang Fashun, Tang Yushang, Chen Minhua.

(2) Third Prize of Science and Technology Progress of Guizhou Province in 2022, Research and Application of Key Technologies based on Three-Dimensional Integrated Multi-Chip Components, completed by Guizhou Zhenhua Fengguang Semiconductor Co., Ltd. and Guizhou University, completed by Li Ping, Tang Tuo, Yang Fashun, Ma Kui, Zhou Dong, Xia Zijin, Li Yang.

· Research Achievements in Industrialization

1. Single-Chip High-Voltage Power Analog Integrated Circuit

With the support of Science and Technology Major Project of Guizhou Province (Research and Industrialization of Key Technologies of Single-Chip High-Voltage Power Analog Integrated Circuit), Engineering Research Center, in collaboration with Guizhou Zhenhua Fengguang Semiconductor Co., Ltd. and the 24th Research Institute of China Electronics Technology Group Corporation, has overcome key process technologies such as power output stage modeling of single-chip high-voltage power analog ics, growth of high-quality thick epitaxial layers, projection lithography of thick epitaxial layers, equal planar wiring, low void rate vacuum soldering, and high current transient testing. The industrialization of a series of single-chip high-voltage power integrated operational amplifiers has been achieved since 2018 , and the series has achieved cumulative sales revenue of over 700 million yuan.

2. Linear Variable Differential Transformer Signal Conditioning Chip

The Engineering Research Center is collaborating with the 58th Research Institute of China Electronics Technology Group Corporation on the research of Linear Variable Differential Transformer (LVDT) signal conditioning technology. The R&D team of the Engineering Center is responsible for the electromagnetic modeling of LVDT and the design and optimization of LVDT signal conditioning chips. The chip has been certified by domestic professional institutions, filling the gap in the field of high-precision LVDT signal conditioning chips in China. The 58th Research Institute of China Electronics Technology Group Corporation began to switch to order version tape-out and mass production in June 2023. Up to now, the project's products have accumulated sales of nearly 5 million yuan.

3. High Precision Rail to Rail Integrated Operational Amplifier

The power device and power integrated circuit research team of the Engineering Research Center in collaboration with Guizhou Chensi Electronic Technology Co., LTD is conducting research and development on high-quality analog integrated circuit chips. The two sides have been working together since the second half of 2019 to develop high-precision rail-to-rail integrated operational amplifiers. After multiple optimization designs and tape-out trials, in May 2023, we achieved industrialization of high-precision rail-to-rail integrated operational amplifiers, with cumulative sales exceeding 10 million yuan.

III. Member Plaque Show

Figure 5 Member unit plaque