【Member News】Gallium Oxide Substrate Cost Slashed by 90%! DG Method Revolutionizes Crystal Growth as NCT and NEDO Drive Industry Transformation

日期:2025-12-22阅读:31

Novel Crystal Technology, Inc., an implementing organization of the NEDO project titled “Economic Security–Focused Key Technology Development Program / High-Output and High-Efficiency Power Devices / Materials Technology Development for High-Frequency Devices / Development of β-Ga₂O₃ Wafers, Power Devices, and Power Modules” (hereinafter referred to as “the Project”), has recently succeeded in developing a crystal growth method that does not require the use of precious-metal crucibles.

This newly developed method supplies the molten source material in the form of droplets and has therefore been named the Drop-fed Growth (DG) method.

Compared with the conventional Edge-Defined Film-Fed Growth (EFG) method, the DG method enables a significant reduction in the use of iridium, an extremely expensive precious metal. As a result, the manufacturing cost of Gallium Oxide (β-Ga₂O₃) substrates can be reduced to one-tenth of the conventional level.

Figure 1. Crystal grown using the newly developed DG method

Background

β-Ga₂O₃※¹ possesses excellent material properties and can be used to fabricate low-loss power devices※². It is expected to be applied to power electronic equipment required for medium-voltage (several hundred volts) markets, such as home appliances, industrial equipment, and electric vehicles, as well as high-voltage (several kilovolts) markets, including railway systems and electric power infrastructure. Consequently, multiple large-scale national projects related to β-Ga₂O₃ are currently underway both domestically and internationally, with active progress in both material development and device development.

Since 2015, NCT has been manufacturing β-Ga₂O₃ substrates using the Edge-Defined Film-Fed Growth (EFG) method. However, because the melting point of the source material is as high as approximately 1800 °C, the EFG method requires the extensive use of iridium—an extremely expensive precious metal capable of withstanding such high temperatures—as the crucible material. This has made cost reduction particularly challenging. To address this issue, NCT has developed its own proprietary β-Ga₂O₃ crystal growth method that does not require iridium crucibles, and development under this project has been underway since 2024.

Results of This Work

By improving both the heating method and the source material supply process, a β-Ga₂O₃ crystal with a diameter of 95 mm was successfully grown without the use of an iridium crucible.

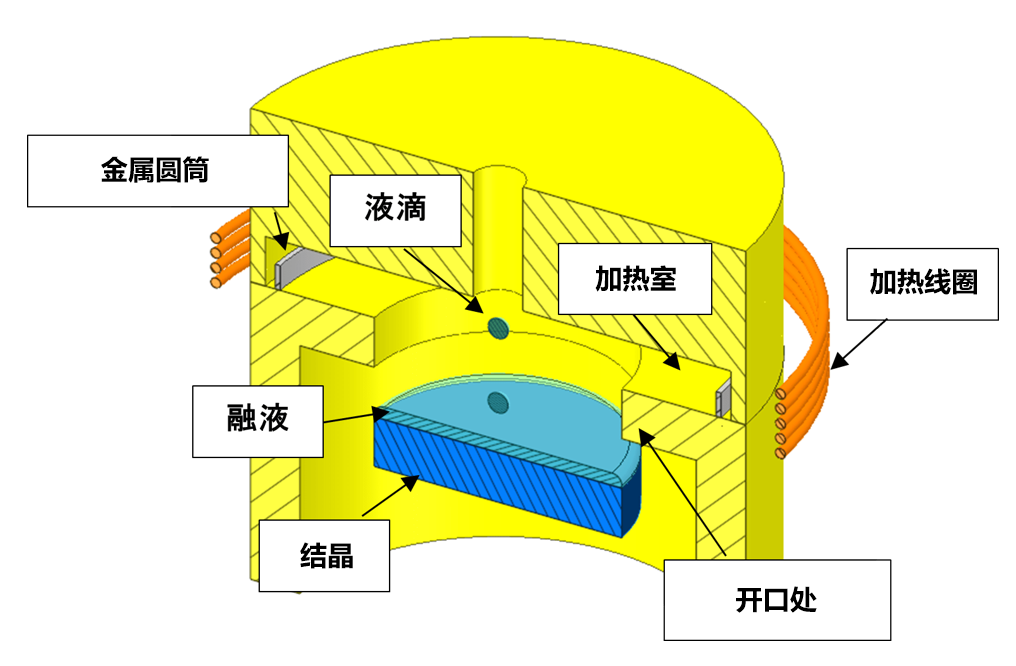

In this method, a metal cylinder is heated using induction heating※³, and the temperature inside the heating chamber is increased such that the crystal (seed crystal) surface is heated and melted by thermal radiation emitted from the opening of the heating chamber. Owing to the geometry of this opening, the temperature distribution on the crystal surface can be more readily controlled, enabling the formation of an optimal temperature profile matched to the crystal diameter. This facilitates the growth of large-diameter crystals. In addition, while the crystal is lowered, molten source material is continuously supplied to the crystal surface in the form of droplets, allowing crystal growth to proceed without the use of the iridium crucible required in conventional methods (Figure 2).

The newly developed DG method has the following characteristics:

● It does not require the use of precious-metal crucibles, enabling a significant reduction in iridium consumption.

● By heating and melting the crystal growth surface, it facilitates the growth of large-diameter crystals.

● Continuous feeding of the source material allows the fabrication of long-length crystals.

Figure 2. Schematic diagram of the crystal growth apparatus

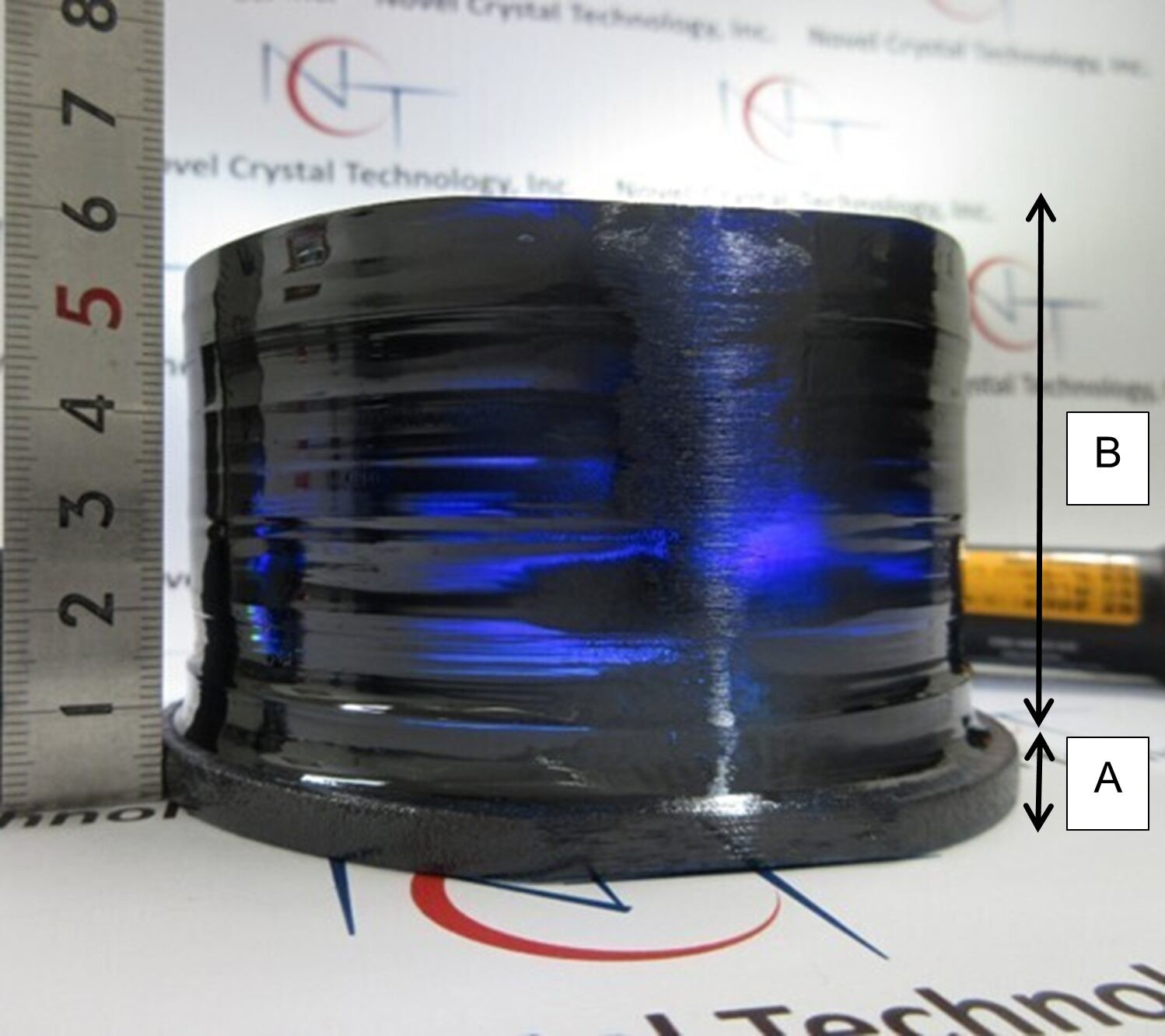

Figure 3 shows a β-Ga₂O₃ crystal with a diameter of 95 mm grown using the DG method. Region A corresponds to the seed crystal, while region B above it is the grown crystal. The crystal has a cylindrical shape with a growth length of 50 mm. By introducing dopant impurities, the crystal was rendered n-type. When only n-type dopants are added, β-Ga₂O₃ crystals appear blue, and the grown region exhibits a deep blue color, confirming its n-type conductivity.

Figure 3. Crystal grown using the DG method

(Region A corresponds to the seed crystal, and region B indicates the grown length.)

It is estimated that, by significantly reducing the consumption of the precious metal iridium and through other measures, the DG method can reduce the manufacturing cost of β-Ga₂O₃ substrates to one-tenth of that of the conventional EFG method.

In addition, patents related to the DG method have been filed both domestically and internationally, and the patent rights are currently being pursued.

Japan: Patent No. 7633637 (granted); JP 2025-061932 (under examination)

United States: US 11,725,299 B2 (granted); US 12,163,246 B2 (granted)

Europe: EP 3 945 147 A1 (under examination)

China: CN 114000188 A (under examination)

Future Plans

NCT will continue to advance the scale-up of the DG method to larger diameters and further improve crystal quality. The company plans to begin shipping 150 mm (6-inch) substrates from 2029, followed by 200 mm (8-inch) substrates from 2035.

Notes

※¹ β-Ga₂O₃: A compound composed of gallium and oxygen, classified as a wide-bandgap semiconductor.

※² Power devices: Semiconductor devices capable of controlling high voltages and high currents, used in power conversion equipment such as inverters.

※³ Induction heating: A heating method used in crystal growth in which a high-frequency current is applied to a coil to generate a magnetic field, inducing eddy currents in metal components (such as crucibles) placed inside the coil, thereby generating heat.

Learn more/WENDER-SINO

Novel Crystal Technology, Inc. (NCT), Japan, is the world’s first company engaged in the research, development, and production of Gallium Oxide substrates, epitaxy, and devices. As the pioneer in the global Gallium Oxide field, NCT integrates substrate manufacturing, epitaxial growth, and device R&D and production. From crystal growth and substrate fabrication to epitaxy and device development, NCT remains at the forefront of the global Gallium Oxide industry, driving the industrialization of Gallium Oxide technologies.

Wonder-Sino Group, as NCT’s designated agent in China, is fully responsible for brand marketing, market promotion, and after-sales services for NCT in the Chinese region. Adhering to the core philosophy of “leading-edge technologies and customer-oriented service,” the company leverages world-class advanced technologies to deliver deeply customized, integrated solutions combining materials + equipment + process, creating irreplaceable industrial value for customers.

NCT continues to focus deeply on Gallium Oxide, a core material in the fourth-generation ultrawide-bandgap semiconductor field, advancing the full industrial chain—from substrates to epitaxy and devices—while driving technological innovation across the industry. Currently, NCT’s full range of Gallium Oxide products has passed rigorous verification by major global research institutions and leading enterprises, with related reports published. For more information, please visit the “News” section on the Wonder-Sino website (www.wonder-sino.com).

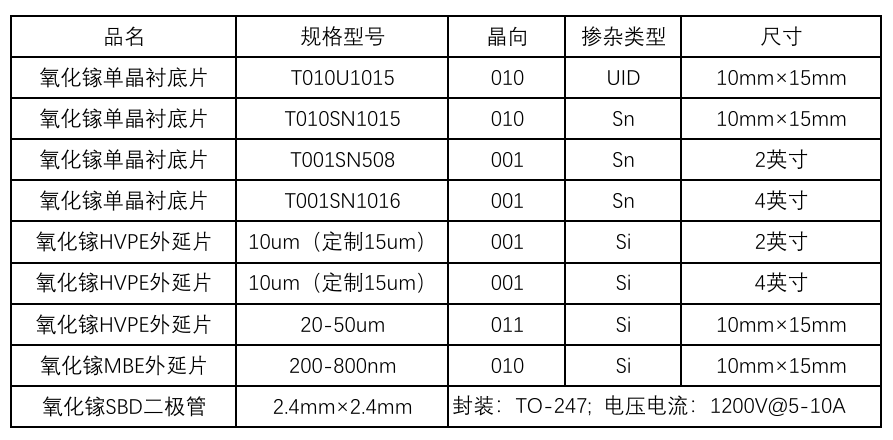

Related product specifications are provided below:

Looking ahead, NCT will continue to increase investment in Gallium Oxide material research and is committed to providing higher-quality products for global customers. At the same time, NCT will work together with Wonder-Sino to explore the unlimited potential of Gallium Oxide materials and contribute to the innovative development of the global Gallium Oxide industry.

For further product information, please contact:

Contact Person: Ms. Guo – 13164023887

Email: gxm@wonder-sino.com

Website: www.wonder-sino.com