【Domestic Papers】Interfacial synergy in mesoporous silica–supported Ga₂O₃ composites enables efficient dye degradation

日期:2026-01-08阅读:17

Researchers from the Henan University have published a dissertation titled "Interfacial synergy in mesoporous silica–supported Ga2O3 composites enables efficient dye degradation" in Applied Surface Science.

Project Support

This work was financially supported by the Key Research and Development Program of Henan Province (Grant No. 221111230100 and 231111233100), the Science and Technology Development Program of Henan Province (Grant No. 232102230019), the Science and Technology Development Plan of Jiyuan City (Grant No. 23022002 and 24012001) and Postgraduate Education Reform and Quality Improvement Project of Henan Province (Grant No. YJS2024JD28).

Background

The industrial production of textiles, plastics and printed materials consumes a substantial amount of organic dyes of which 10–20 % are discharged into wastewater, posing a significant threat to ecosystems. These dyes exhibit diverse compositions, biotoxicity and bioaccumulation properties, with some identified as carcinogenic and mutagenic to humans. Therefore, the development of efficient wastewater treatment technology has become essential for sustainable environmental protection.

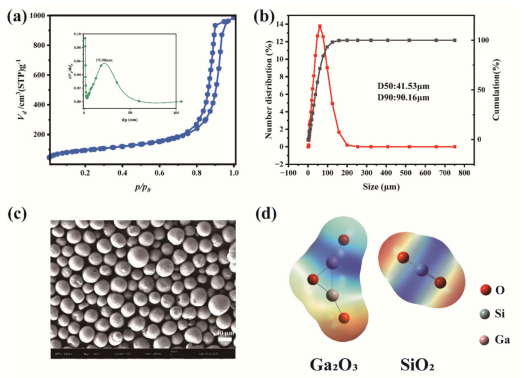

In this work, we report a high-yield strategy for the synthesis of mesoporous silica microparticles via spray-drying of nano-silica aqueous slurries containing 8–12 wt% solids. Mesoporous silica with spherical morphology, narrow particle size distribution and high porosity was prepared and subsequently employed as a support for loading Ga2O3 catalysts. The resulting Ga2O3/SiO2 composites were thoroughly characterized, and their adsorption and photocatalytic performances were evaluated against Rhodamine B (RhB) and Methylene Blue (MB) under both dark and UV-light (24 W) conditions. Among all samples, the GS3 composite (3 wt% Ga2O3 loading) showed the highest degradation efficiency. The enhanced removal performance was attributed to the synergistic effect of high surface area-driven adsorption and Ga2O3-enhanced photocatalysis. This study provides a robust route for the scalable fabrication of mesoporous silica-based photocatalysts and highlights a promising strategy for the efficient removal of dye pollutants from wastewater.

Abstract

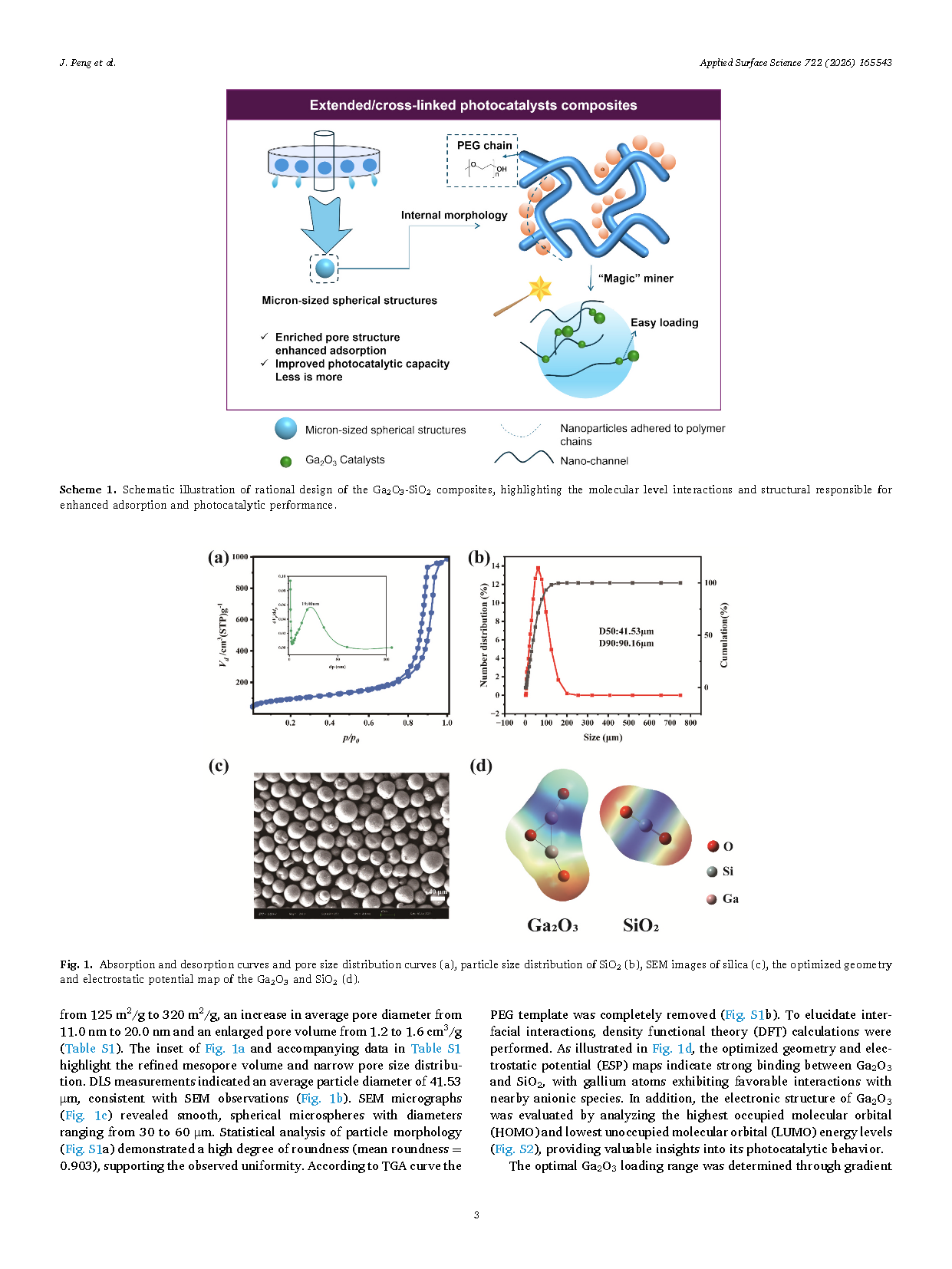

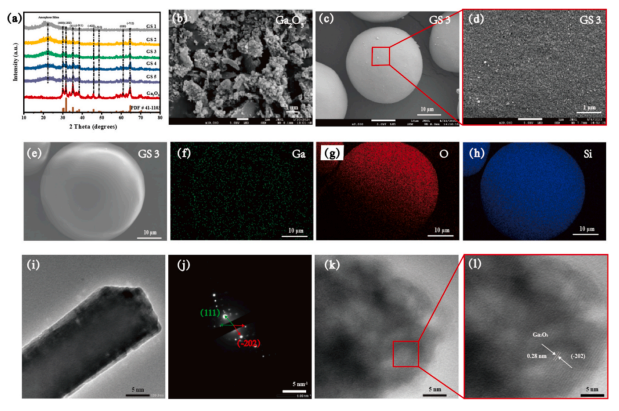

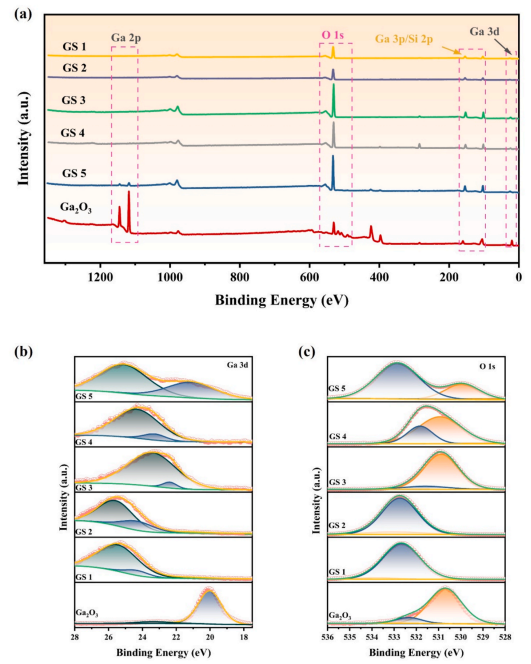

Catalyst supports play a critical role in suppressing nanoparticle agglomeration and enhancing catalytic performance. Here, mesoporous silica microspheres (40–45 μm) were synthesized via spray-drying of silica filter cake with polyethylene glycol (PEG) as a pore-forming agent. The resulting particles exhibited highly ordered mesostructure with large specific surface areas (300–400 m2/g) and pore volumes (1.5–1.6 cm3/g), providing an ideal scaffold for Ga2O3 loading. Ga2O3-SiO2 composites were prepared by wet impregnation, achieving uniform Ga2O3 dispersion within the mesoporous framework. The composites were evaluated for the photodegradation of Rhodamine B (RhB) and Methylene Blue (MB) under UV irradiation. Superior performance was observed, with the optimized catalyst achieving >96 % dye removal within 120 min. The enhanced activity arose from the synergistic combination of high adsorption capacity, ensuring intimate dye-catalyst contact, and Ga2O3-driven photocatalysis. A lattice coupling mechanism is proposed, wherein the silica support modulates the Ga2O3 electronic structure, suppressing electron-hole recombination and improving charge separation. Mechanistic insights from DFT, XPS, and SEM analyses confirmed structure–activity relationships. This study demonstrates a scalable strategy for fabricating Ga2O3-based composites and highlights their potential as efficient photocatalysts for dye-contaminated wastewater treatment.

Highlights

● Mesoporous silica microspheres were synthesized via spray-drying as catalyst support.

● Ga2O3-SiO2 composites were prepared with Ga2O3 dispersion in the mesoporous scaffold.

● The GS3 composite catalyst exhibited outstanding photocatalytic performance.

Conclusion

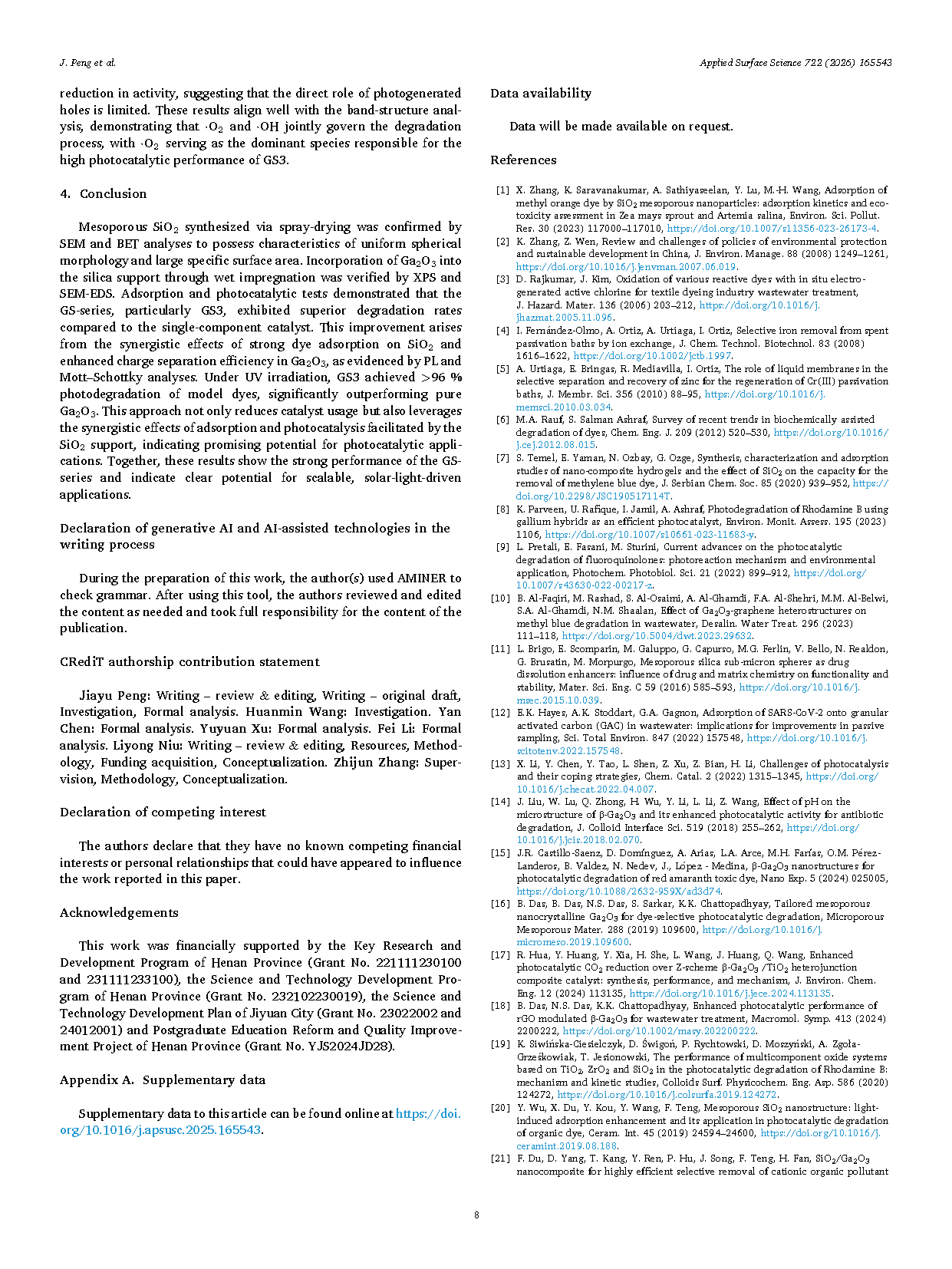

Mesoporous SiO2 synthesized via spray-drying was confirmed by SEM and BET analyses to possess characteristics of uniform spherical morphology and large specific surface area. Incorporation of Ga2O3 into the silica support through wet impregnation was verified by XPS and SEM-EDS. Adsorption and photocatalytic tests demonstrated that the GS-series, particularly GS3, exhibited superior degradation rates compared to the single-component catalyst. This improvement arises from the synergistic effects of strong dye adsorption on SiO2 and enhanced charge separation efficiency in Ga2O3, as evidenced by PL and Mott–Schottky analyses. Under UV irradiation, GS3 achieved >96 % photodegradation of model dyes, significantly outperforming pure Ga2O3. This approach not only reduces catalyst usage but also leverages the synergistic effects of adsorption and photocatalysis facilitated by the SiO2 support, indicating promising potential for photocatalytic applications. Together, these results show the strong performance of the GS-series and indicate clear potential for scalable, solar-light-driven applications.

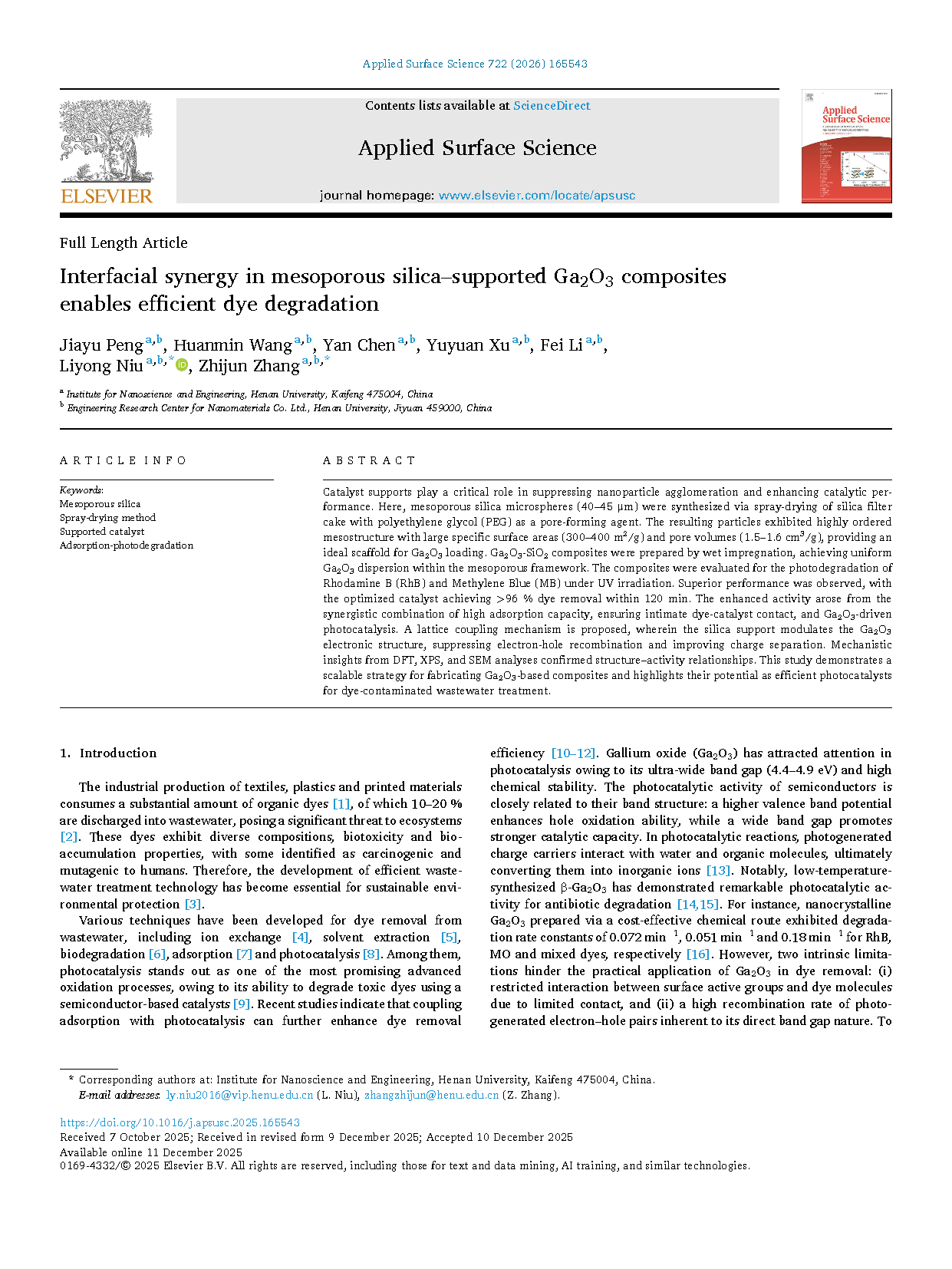

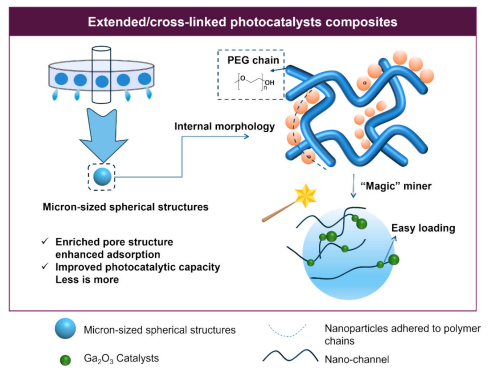

Scheme 1. Schematic illustration of rational design of the Ga2O3-SiO2 composites, highlighting the molecular level interactions and structural responsible for enhanced adsorption and photocatalytic performance.

Fig. 1. Absorption and desorption curves and pore size distribution curves (a), particle size distribution of SiO2 (b), SEM images of silica (c), the optimized geometry and electrostatic potential map of the Ga2O3 and SiO2 (d).

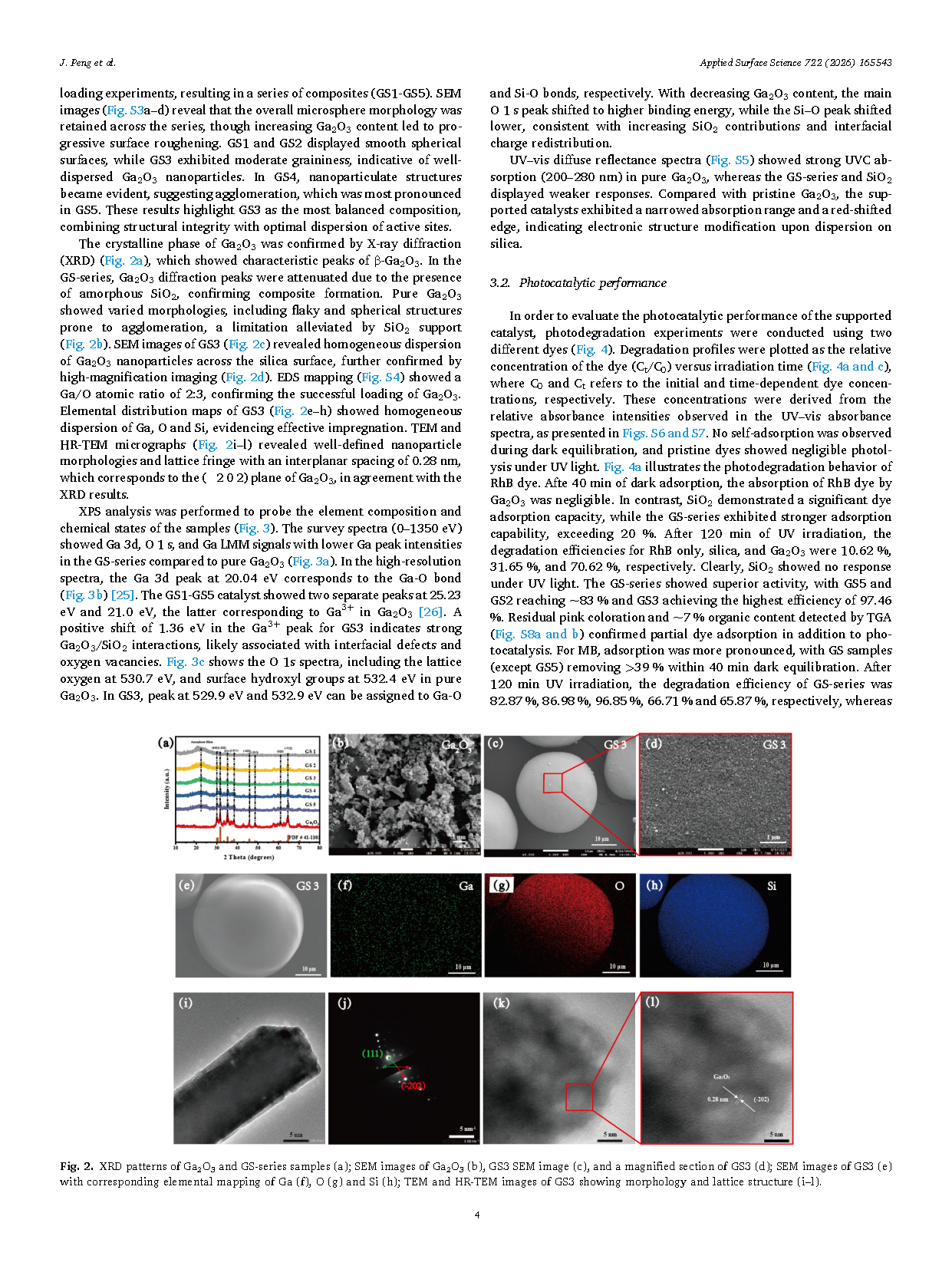

Fig. 2. XRD patterns of Ga2O3 and GS-series samples (a); SEM images of Ga2O3 (b), GS3 SEM image (c), and a magnified section of GS3 (d); SEM images of GS3 (e) with corresponding elemental mapping of Ga (f), O (g) and Si (h); TEM and HR-TEM images of GS3 showing morphology and lattice structure (i–l).

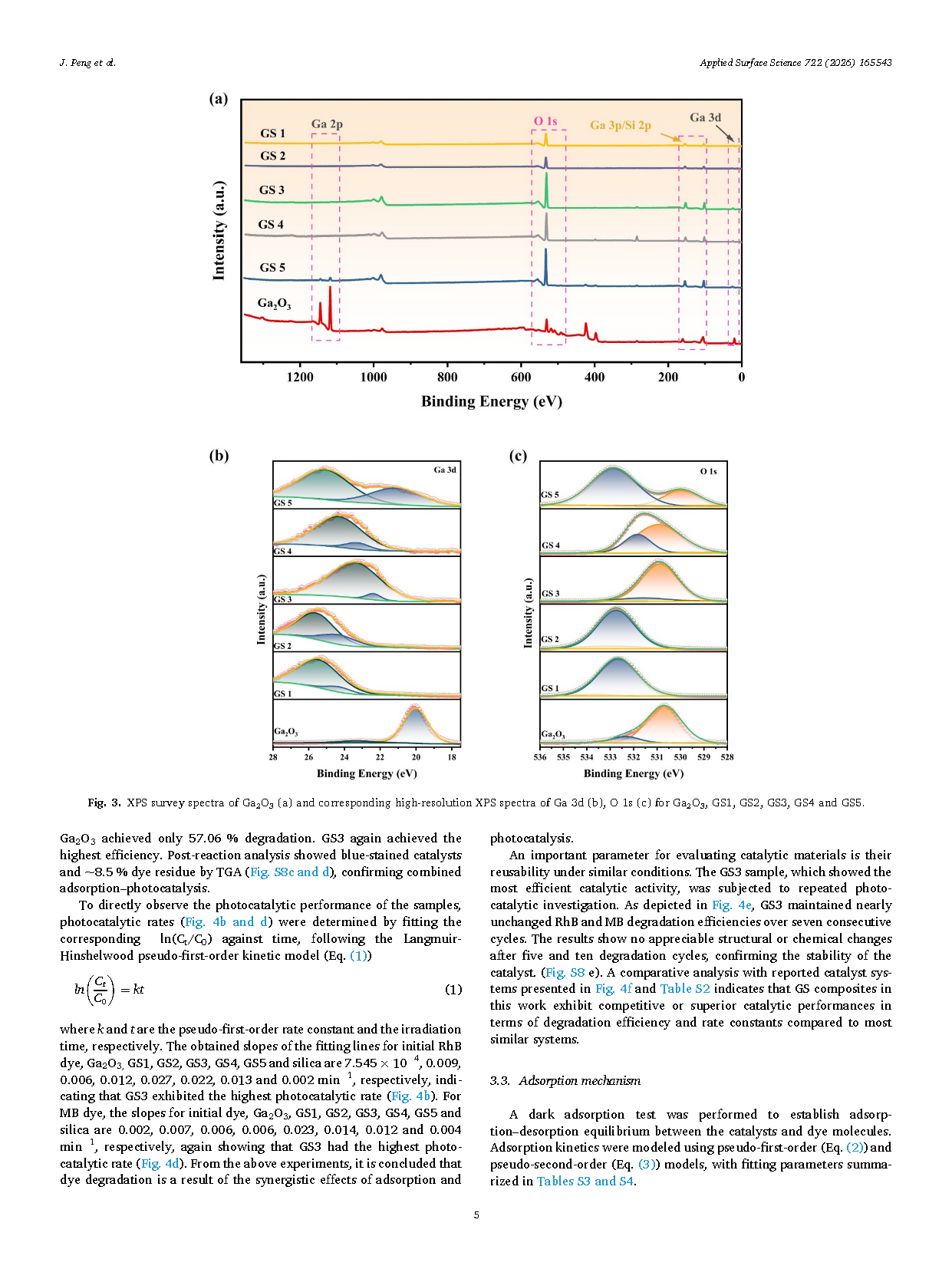

Fig. 3. XPS survey spectra of Ga2O3 (a) and corresponding high-resolution XPS spectra of Ga 3d (b), O 1s (c) for Ga2O3, GS1, GS2, GS3, GS4 and GS5.

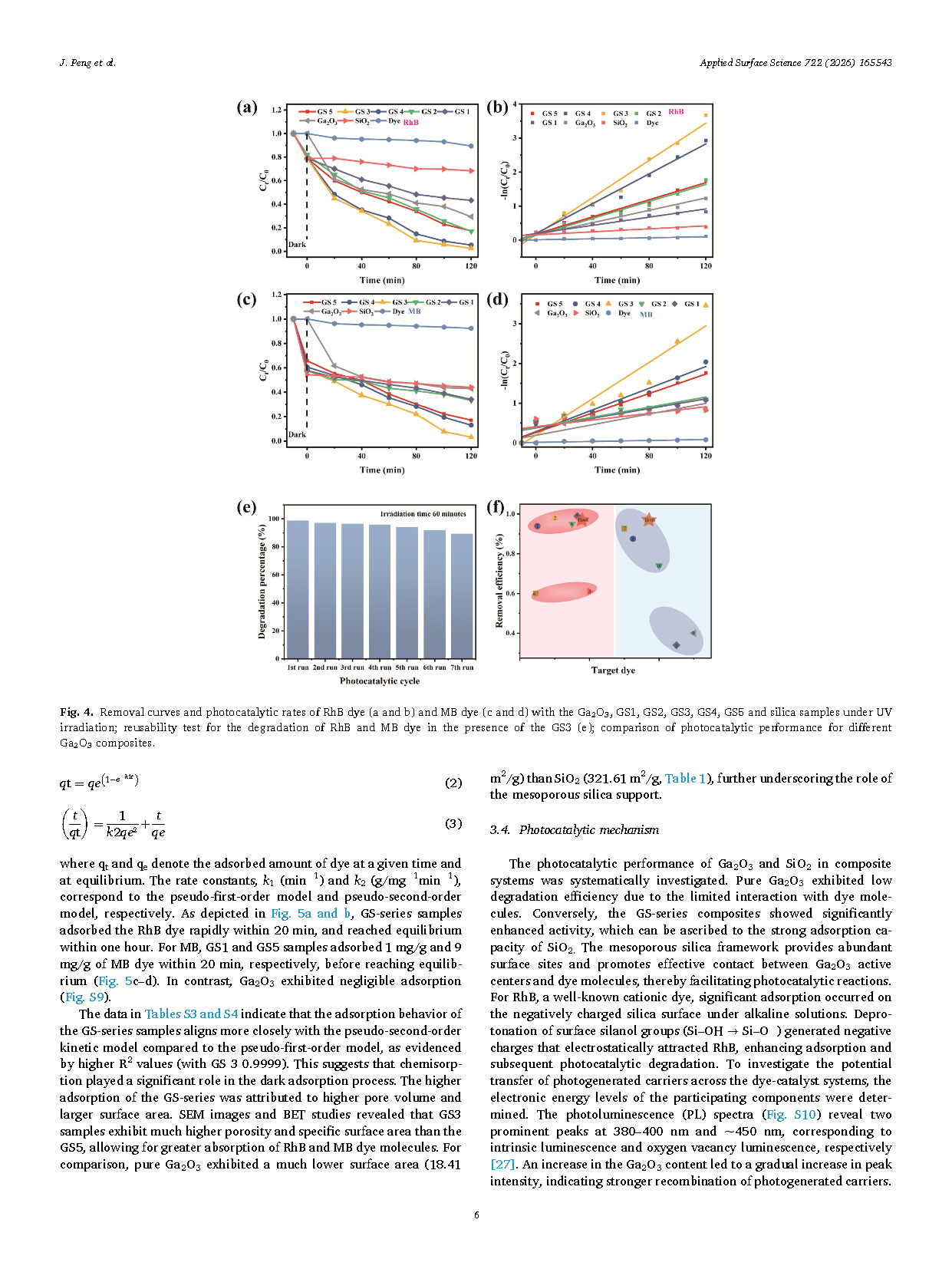

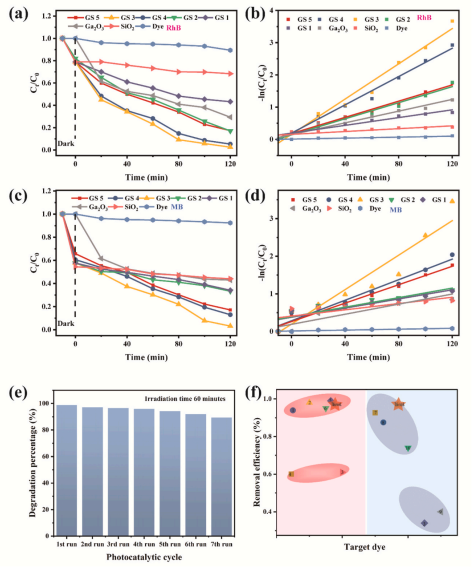

Fig. 4. Removal curves and photocatalytic rates of RhB dye (a and b) and MB dye (c and d) with the Ga2O3, GS1, GS2, GS3, GS4, GS5 and silica samples under UV irradiation; reusability test for the degradation of RhB and MB dye in the presence of the GS3 (e); comparison of photocatalytic performance for different Ga2O3 composites.

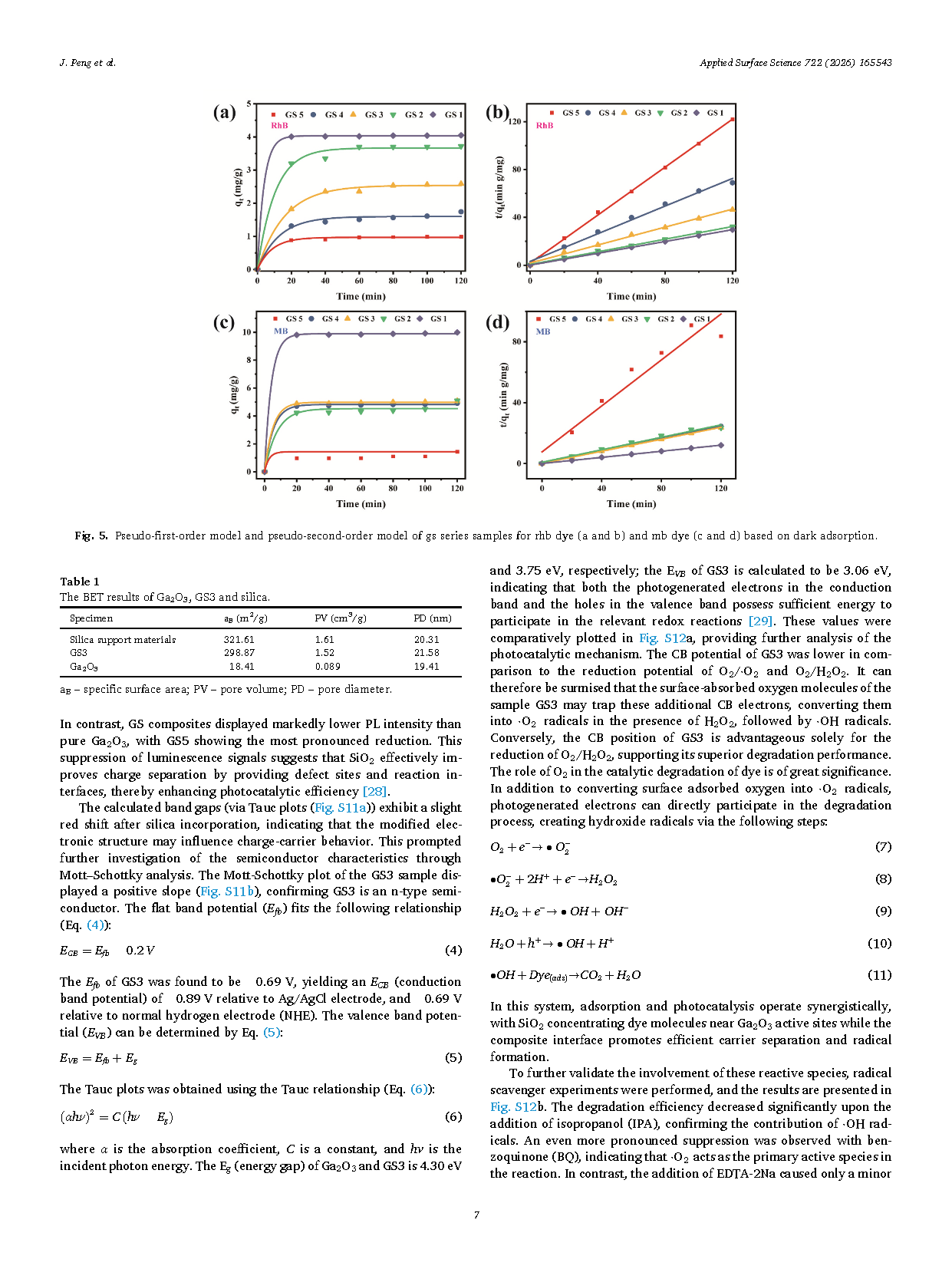

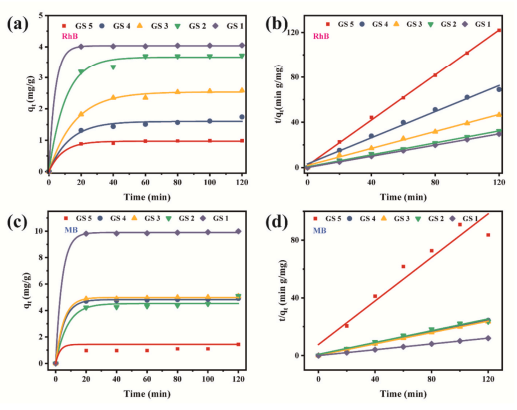

Fig. 5. Pseudo-first-order model and pseudo-second-order model of gs series samples for rhb dye (a and b) and mb dye (c and d) based on dark adsorption.

DOI:

doi.org/10.1016/j.apsusc.2025.165543