【Member Intro】Shandong Extreme Temperature New Material Co., LTD —— Regular Member

日期:2024-08-01阅读:1526

Company Profile

Shandong Extreme Temperature New Materials Co., Ltd. is an innovative zirconia fiber new material enterprise jointly established by Professor Xu Dong's team of Crystal Materials Research Institute of Shandong University and Shandong Yuwang Group. It is located in Yucheng high-tech Industrial Development Zone, Dezhou City, Shandong Province, and is a subsidiary of Shandong Dipole Energy-saving Materials Co., LTD. The company is mainly committed to ultra-high temperature heat insulation, heat insulation energy-saving new materials industry application, in the bipolar thermal insulation fiber materials and related application products have independent patents and proprietary technology, has been included in the National Major Projects, National High-Tech Research and Development Program (863 program), Military Key Projects, National Natural Science Foundation and so on.

The company research and produced for the "bipolar temperature range" oxide thermal insulation energy-saving material zirconia fiber series products have reached the international advanced level. The company has applied for nearly 20 national invention patents, and the products have huge market prospects in the fields of aerospace, iron and steel metallurgy, ceramic sintering, crystal growth, composite materials and so on.

Product Introduction

Zirconia Fiber Cotton

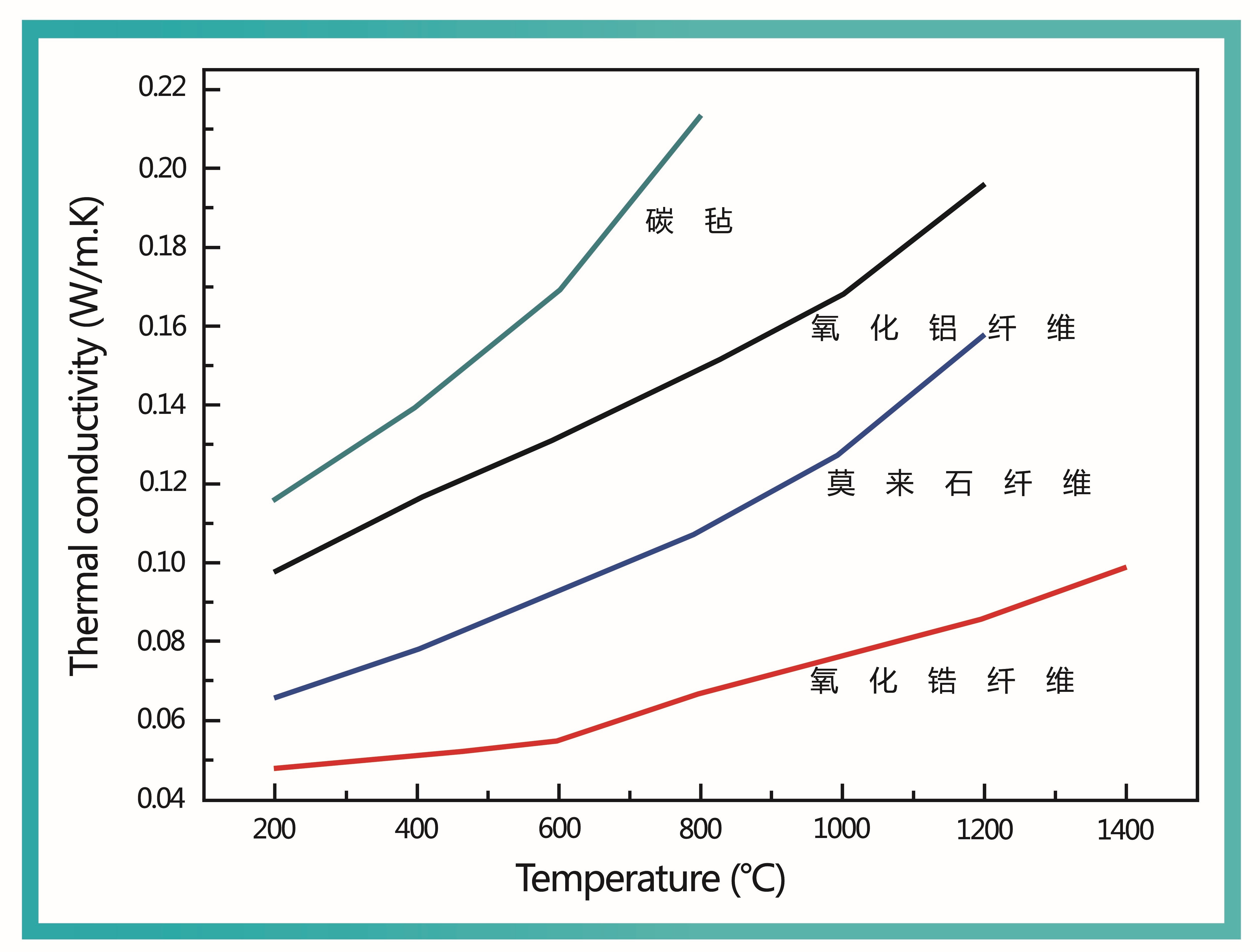

Our company adopts pure inorganic reaction synthesis system, keeping the sol with high polymerization degree, high purity, continuous spinnability and long-term stability at the same time, clean, environmental protection, tasteless, pollution-free. The use of unique high pressure spinning process, continuous production of nanometer and micron zirconia fiber. Zirconia fiber high temperature vapor pressure is small, no volatilization at high temperature, clean, pollution-free. Zirconia fiber has the lowest thermal conductivity among all oxide fibers.

Nanometer fiber cotton diameter 800-1000 nanometers, feel soft and delicate, the appearance compared with micron fiber reflects the obvious layered state, compared with micron fiber made products have lower thermal conductivity.

The diameter of micron fiber cotton is 2-4 microns, and the appearance is stacked cotton. Compared with nanofibers, it has more advantages in cost performance.

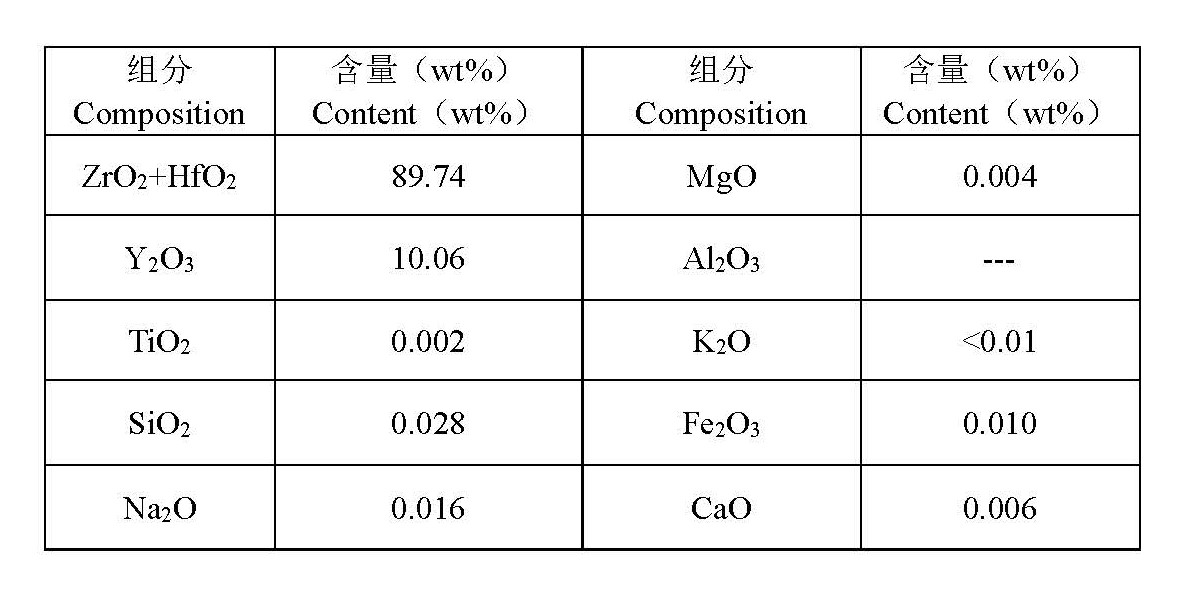

Chemical Composition of Zirconia Fiber Cotton

Micron Grade Fiber Cotton

Nano Grade Fiber Cotton

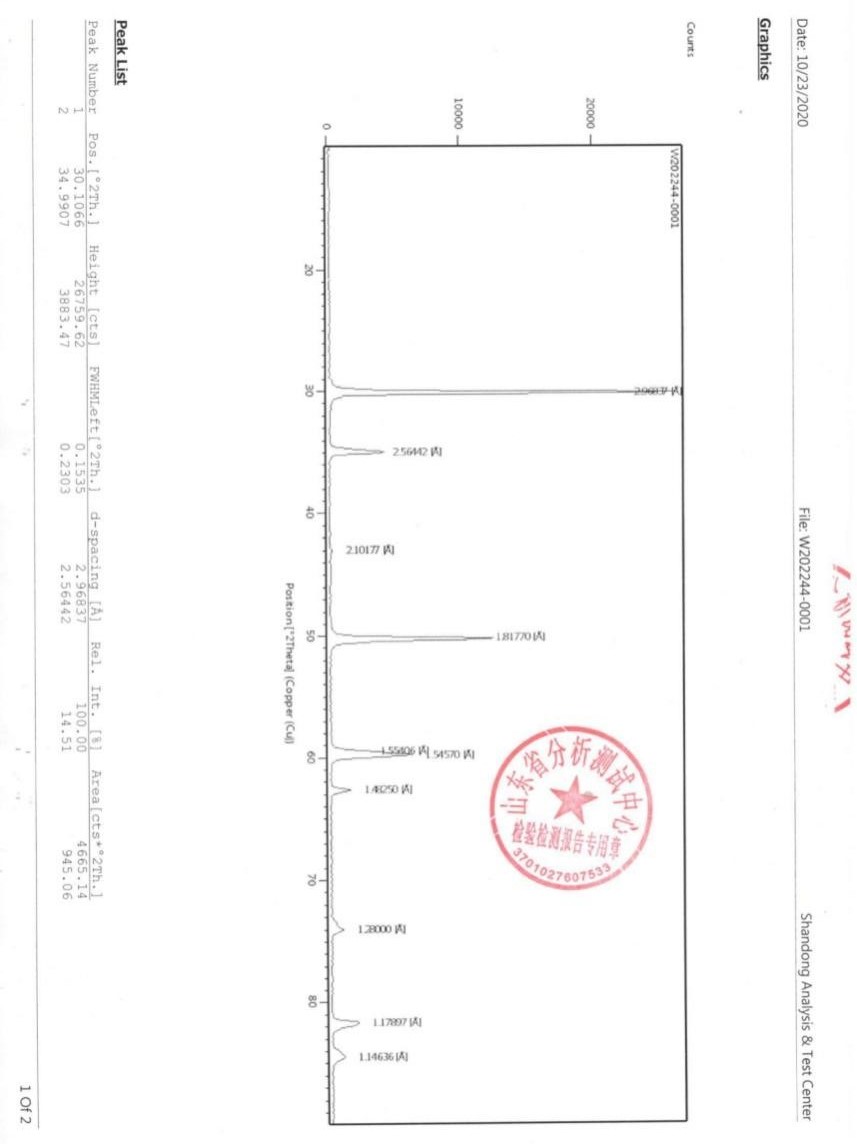

Phase Diffraction Pattern

Comparison of thermal conductivity between zirconia fiber materials and other material

Test Report

Zirconia Fiber Products

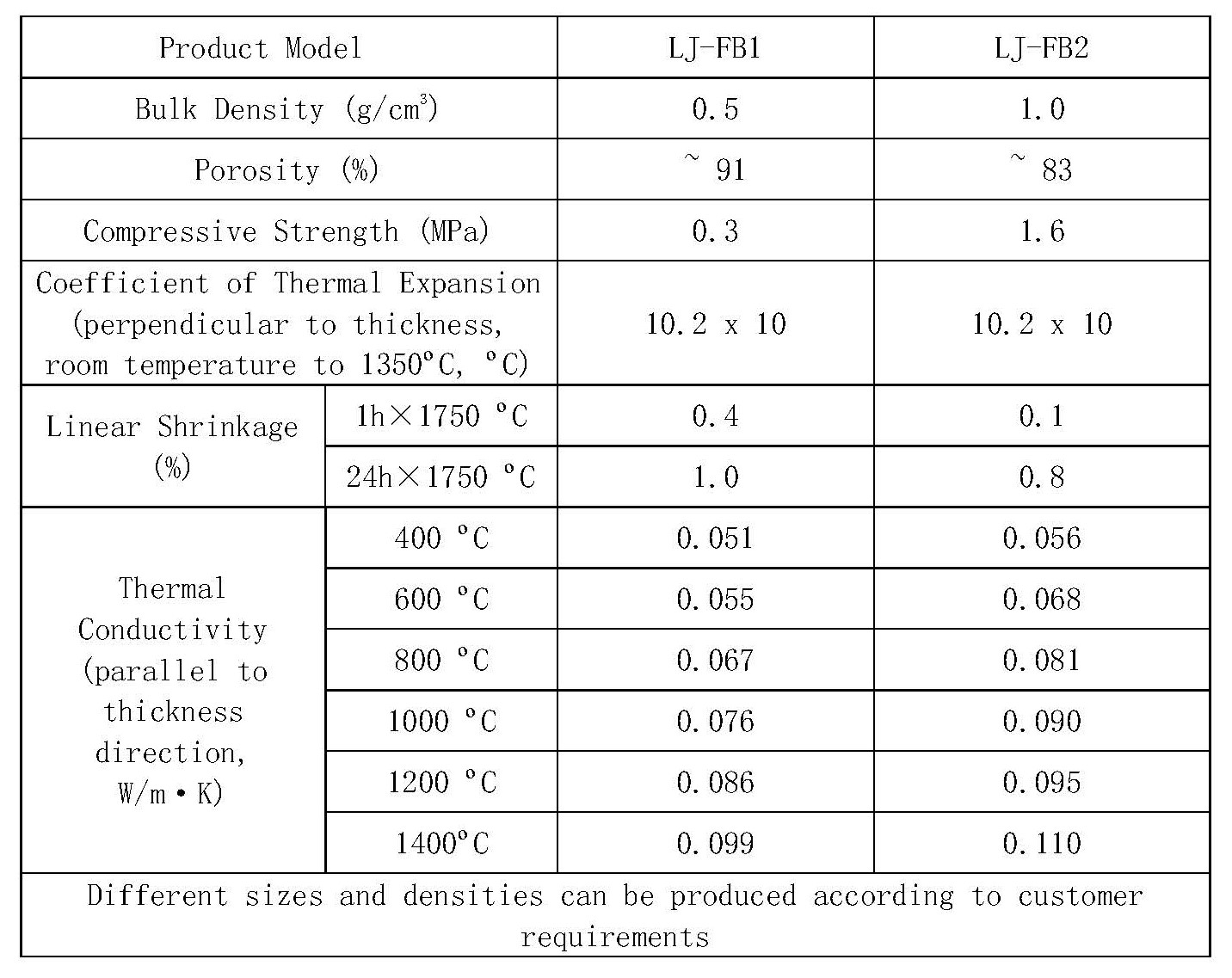

Zirconia fiber products are made of yttrium stabilized zirconia fiber after several processes of production of light fire-resistant energy-saving materials, compared with pure zirconia does not exist phase change. This kind of products after special process treatment, high temperature can still maintain the stability of product size. Zirconia fiber products can be processed into furnace plates, all kinds of special-shaped products; Different density of zirconia fiber products can be customized, with different strength and thermal conductivity. The product can be used in 2200 ºC high temperature environment. It has excellent corrosion resistance.

Basic Features

- Temperature resistance up to 2400ºC, long-term use of 2200ºC

- Very low thermal conductivity 0.099W/m·K(1400ºC)

- High purity (ZrO2+Y2O3) ≥99.8%

- No volatile organic residues

- Oxidation resistance, corrosion resistance chemical properties stable acid and alkali corrosion resistance

- Do not drop powder, do not drop slag appearance smooth

- The shape can be customized according to the requirements of drawings

- Density customizable products with different densities can be customized according to different application fields

Application Field

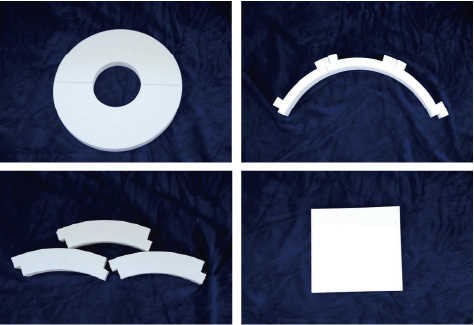

Zirconia combined temperature field for crystal growth

Design Scheme:

- The side screen temperature field is designed with two layers inside and outside. The inner layer is high-density zirconia special-shaped parts and the outer layer is low-density zirconia fiber special-shaped parts;

- Each layer is divided into several pieces, and the child buckle or "Sharp Angle" joint splicing is used between each piece, and the child buckle splicing is used between layers; The height of each layer of the inner and outer layers is different to ensure the sealing and structural stability of the temperature field.

Design Advantages:

- Compared with traditional materials, can greatly reduce the use of power, energy saving up to 40%.

- The dislocation splicing method is adopted in the layer and the layer, which can effectively prevent the cracking and light leakage of the material and ensure the stability of the temperature field of the crystal furnace.

- No volatilization under high temperature environment, reduce temperature field pollution, green environmental protection.

- The crystal quality of zirconia fiber products is better.

- Reduce the thickness of insulation material, greatly improve the utilization rate of the internal space of crystal furnace.

Product Photos

Inner Layer

Outer layer

Inner and outer layer combinations

Zirconia fiber furnace for high temperature furnace

Design Scheme:

- The furnace adopts special structure of all zirconia fiber products furnace.

Design Advantages:

- Compared with traditional materials, can greatly reduce the use of power, energy saving up to more than 30%, the larger the furnace, the higher the temperature, the more obvious energy-saving effect.

- Using the company's special structure, can be used for a long time.

- Long-term use temperature of box furnace can reach 1800 ºC, vacuum furnace can reach 2200 ºC.

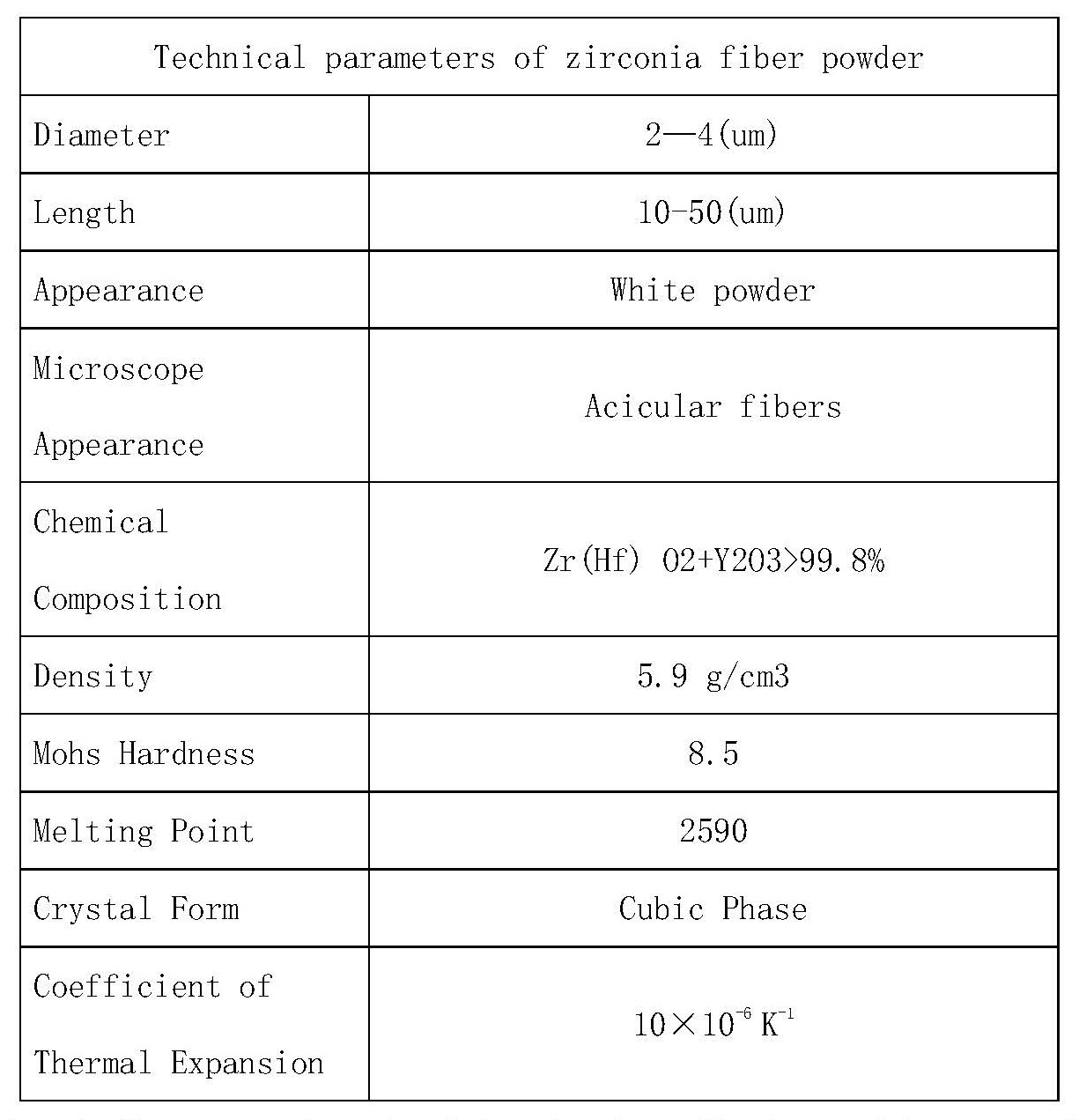

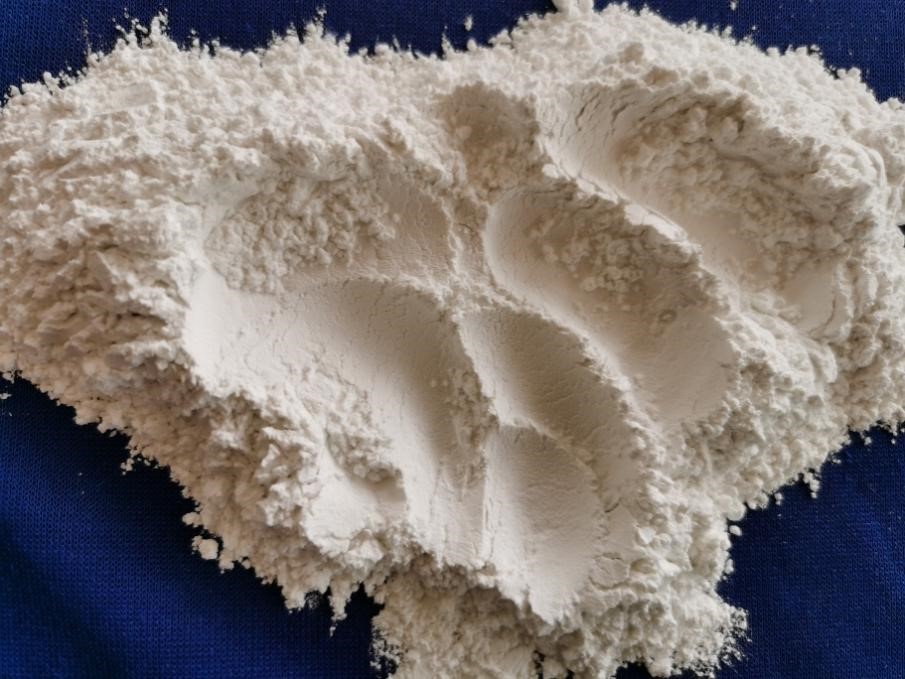

Zirconia fiber powder

Zirconia fiber powder is made of zirconia micron fiber by special process grinding. The appearance is powdery structure, white and delicate, and the microscope is needle-like structure. It can be applied to the enhancement and toughening of various materials.

Publicity Display

Former Premier of the State Council Li Keqiang inspects our company's zirconia fiber at Shandong University

The Chairman of the Group was warmly received by the General Secretary

The thermal insulation performance of the company's products was displayed