【International Papers】A Liquid Metal Balloon for the Exfoliation of an Ultrathin and Uniform Gallium Oxide Layer

日期:2025-02-17阅读:568

Researchers from the Ulsan National Institute of Science and Technology (UNIST) have published a dissertation titled "A Liquid Metal Balloon for the Exfoliation of an Ultrathin and Uniform Gallium Oxide Layer" in Molecules.

Abstract

We report the exfoliation of ultrathin gallium oxide (Ga2O3) films from liquid metal balloons, formed by injecting air into droplets of eutectic gallium–indium alloy (eGaIn). These Ga2O3 films enable the selective adsorption of carbon nanotubes (CNTs) dispersed in water, resulting in the formation of a dense, percolating CNT network on their surface. The self-assembled CNT network on Ga2O3 provides a versatile platform for device fabrication. As an example application, we fabricated a chemiresistive gas sensor for detecting simulants of chemical warfare agents (CWAs), including diisopropyl methylphosphonate (DIMP), dimethyl methylphosphonate (DMMP), and triethyl phosphate (TEP). The sensor exhibited reversible responses, high sensitivity, and low limits of detection (13 ppb for DIMP, 28 ppb for DMMP, and 53 ppb for TEP). These findings highlight the potential of Ga2O3 films derived from liquid metal balloons for integrating CNTs into functional electronic devices.

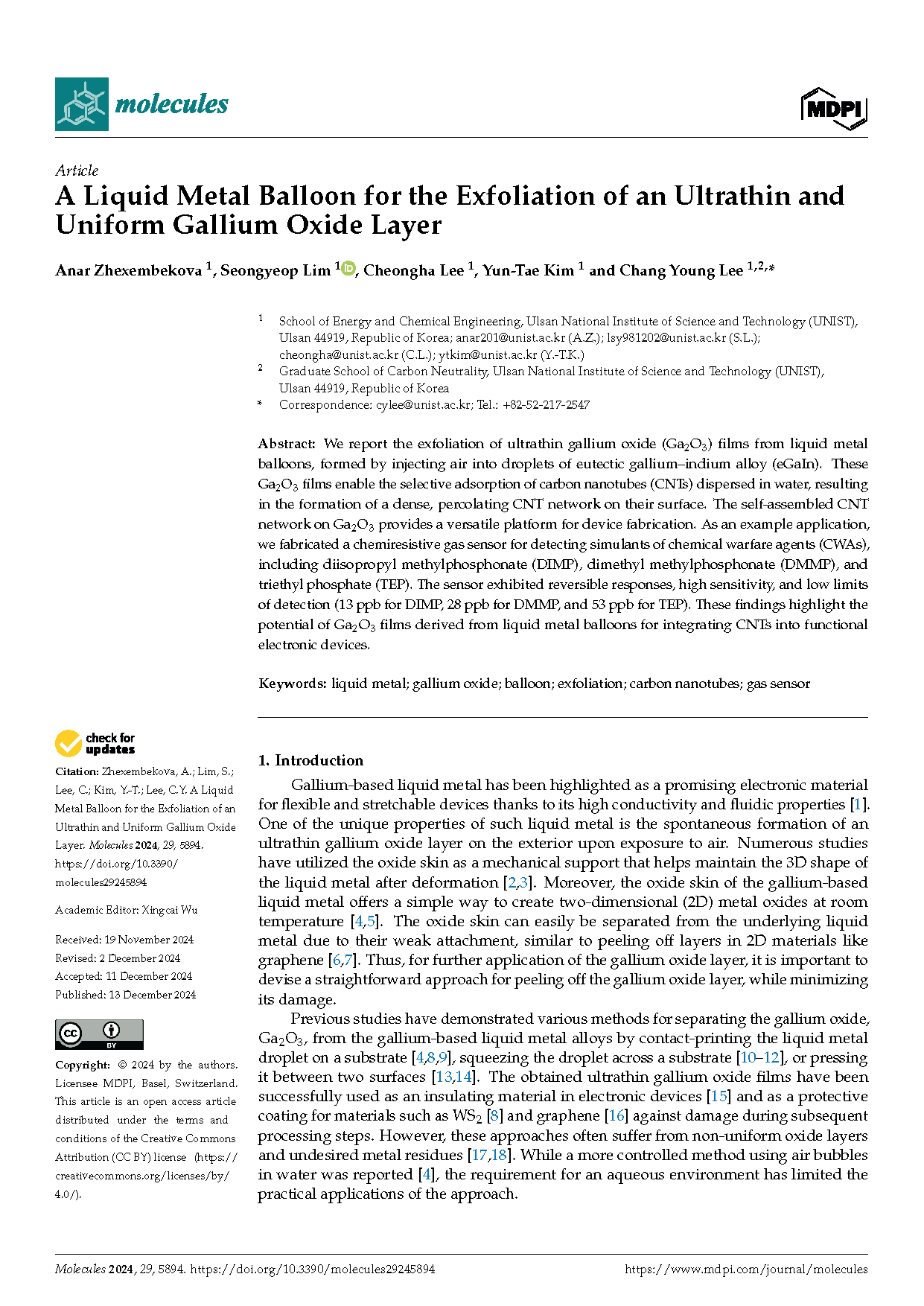

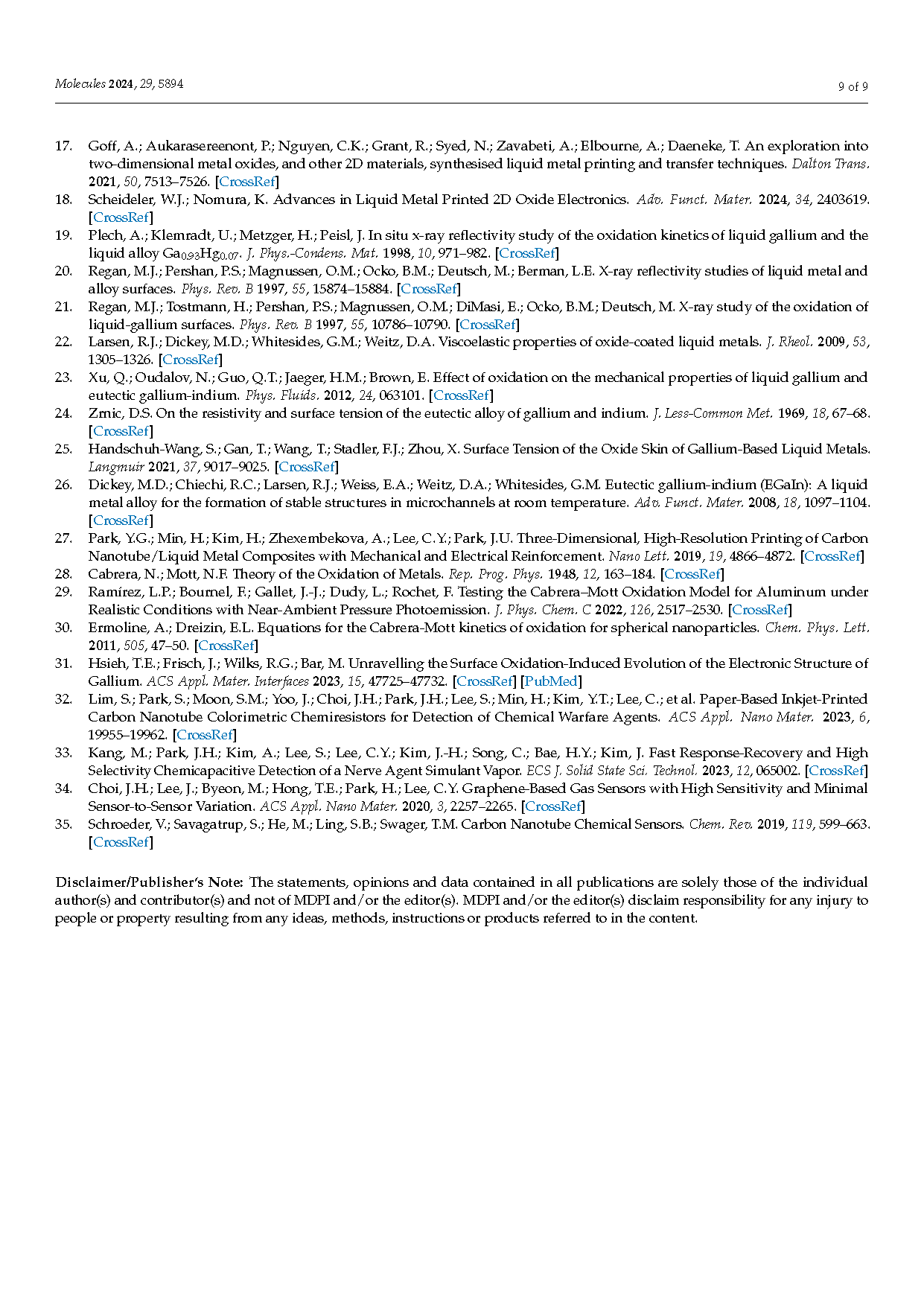

Figure 1. Preparation of a liquid metal balloon. (a) Schematic illustration of the liquid metal balloon formation by injecting air into a liquid metal droplet using a gas-tight syringe. (b) Optical images of an eGaIn droplet before (left) and after (right) air injection, showing a diameter increase from 1 mm to 2.4 mm. (c) Optical images of the liquid metal balloon collected from two different angles. (d) Optical image of the liquid metal balloon after the needle was removed.

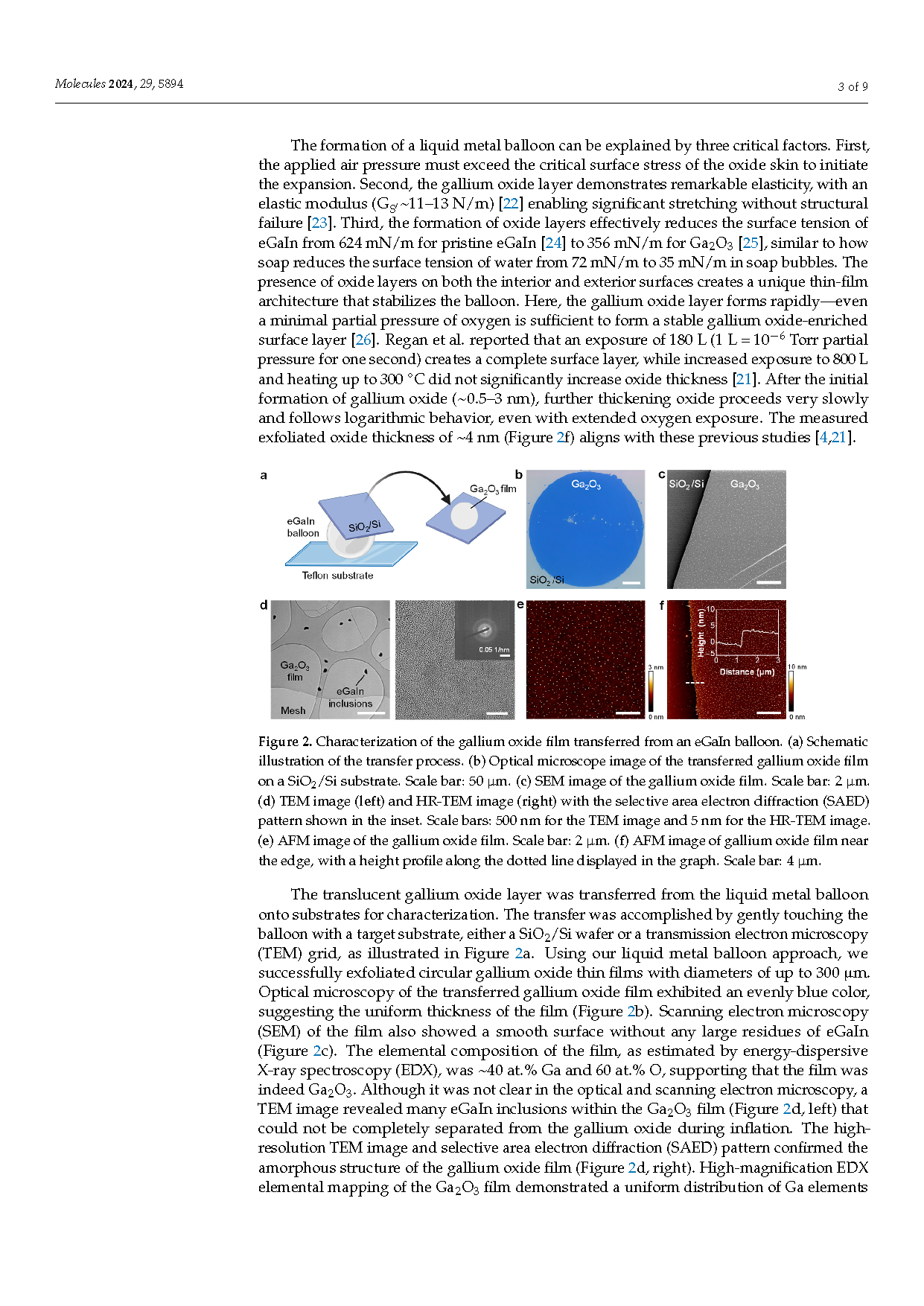

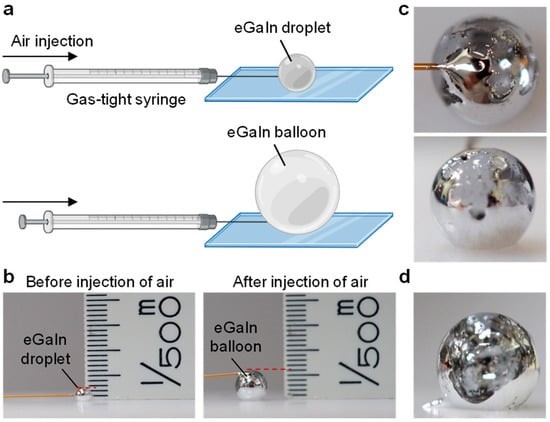

Figure 2. Characterization of the gallium oxide film transferred from an eGaIn balloon. (a) Schematic illustration of the transfer process. (b) Optical microscope image of the transferred gallium oxide film on a SiO2/Si substrate. Scale bar: 50 μm. (c) SEM image of the gallium oxide film. Scale bar: 2 µm. (d) TEM image (left) and HR-TEM image (right) with the selective area electron diffraction (SAED) pattern shown in the inset. Scale bars: 500 nm for the TEM image and 5 nm for the HR-TEM image. (e) AFM image of the gallium oxide film. Scale bar: 2 μm. (f) AFM image of gallium oxide film near the edge, with a height profile along the dotted line displayed in the graph. Scale bar: 4 μm.

DOI:

doi.org/10.3390/molecules29245894