【Domestic Papers】β-Ga₂O₃ Thin Films via an Inorganic Sol–Gel Spin Coating: Preparation and Characterization

日期:2025-03-17阅读:504

Researchers from the Inner Mongolia University of Technology have published a dissertation titled "β-Ga2O3 Thin Films via an Inorganic Sol–Gel Spin Coating: Preparation and Characterization" in Nanomaterials.

Abstract

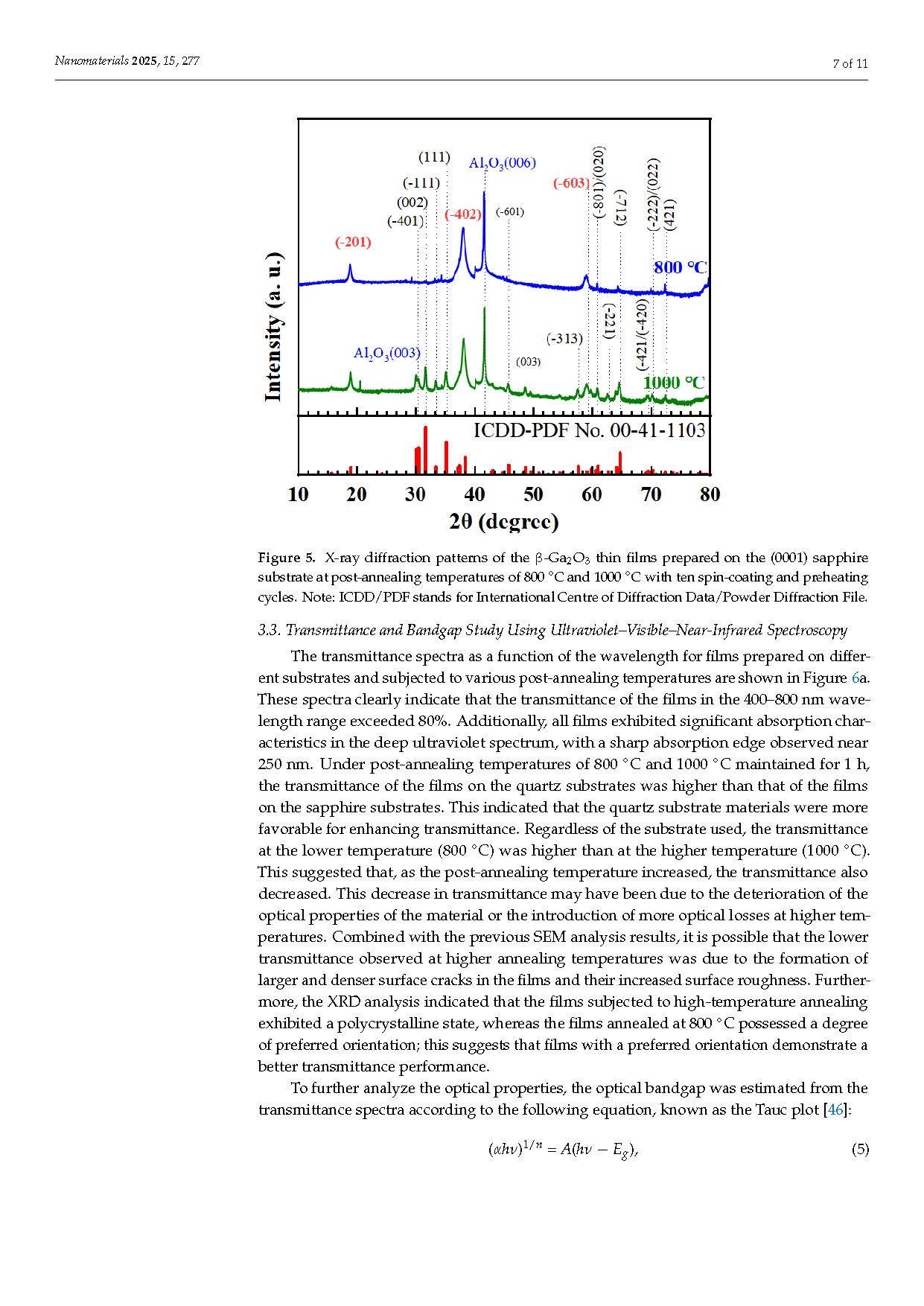

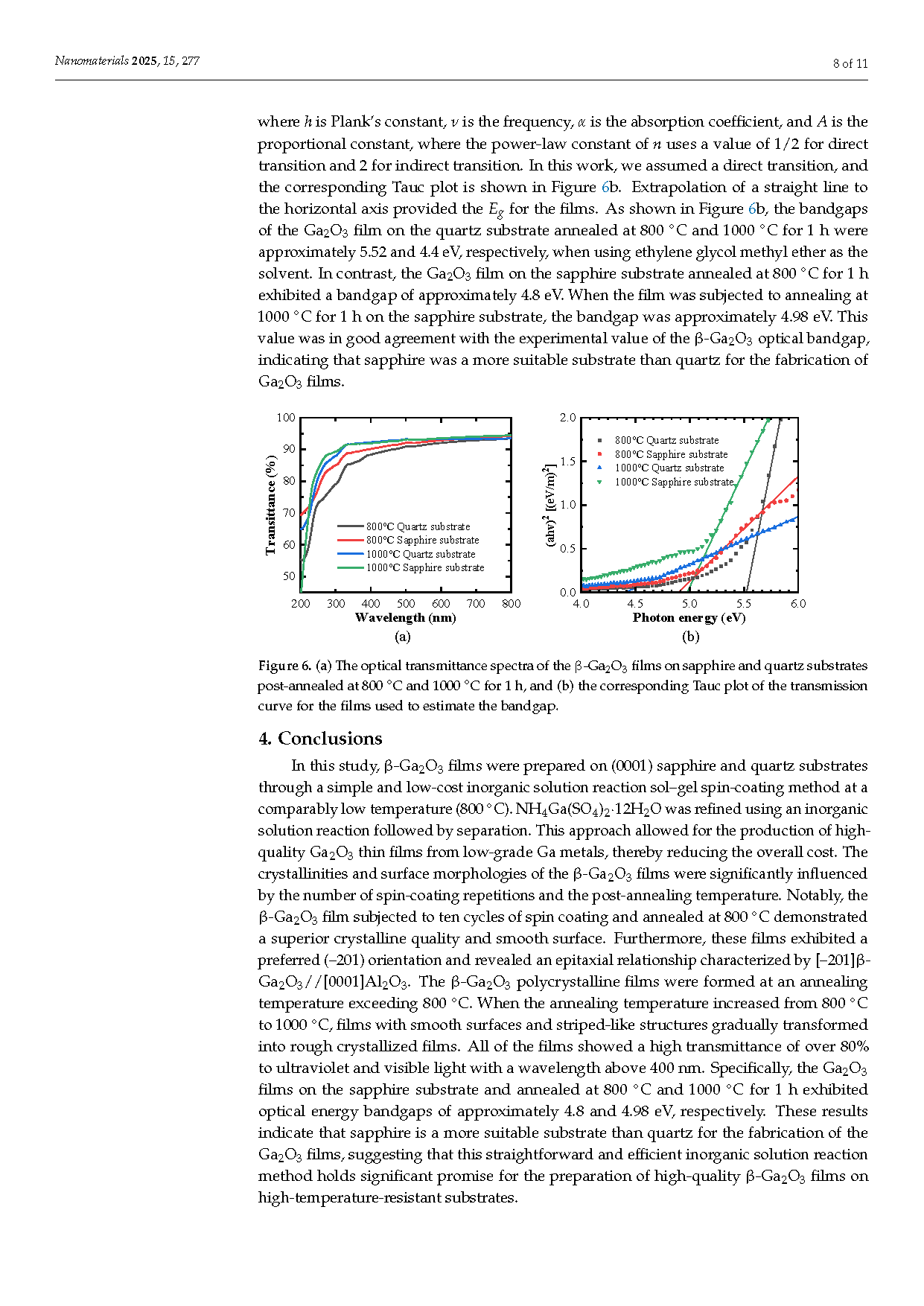

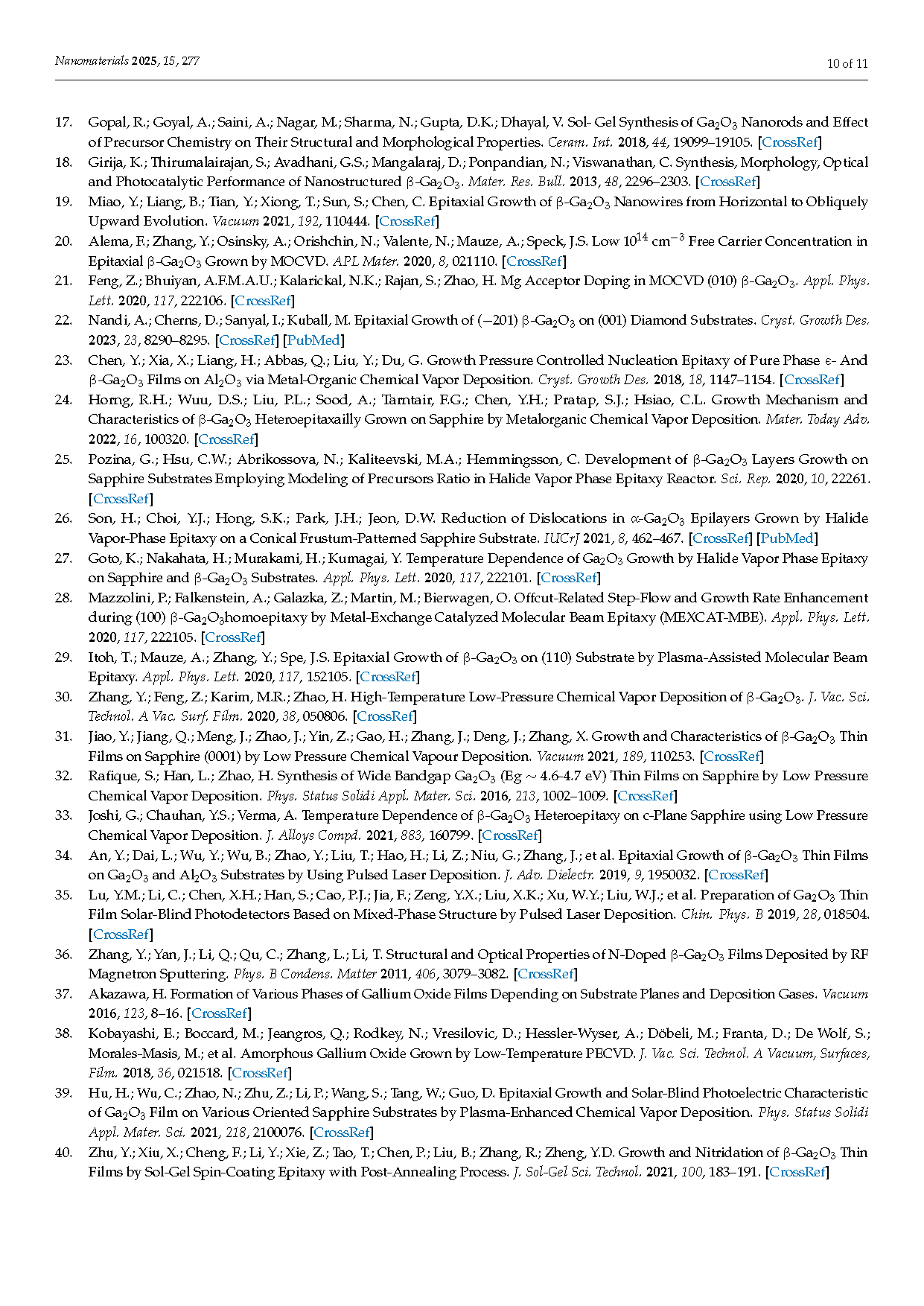

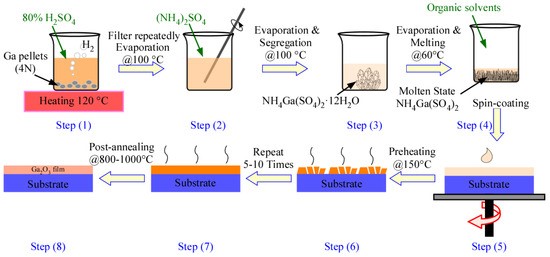

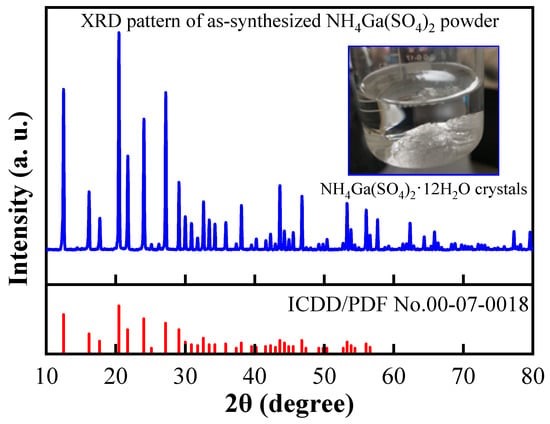

β-Ga2O3 holds significant promise for use in ultraviolet (UV) detectors and high-power devices due to its ultra-wide bandgap. However, the cost-effective preparation of large-area thin films remains challenging. In this study, β-Ga2O3 thin films are prepared using an inorganic solution reaction spin-coating method followed by post-annealing. The structures, surface morphologies, and optical properties of the films are then characterized using X-ray diffraction, scanning electron microscopy, and ultraviolet–visible spectrophotometry. A low-cost Ga metal was used to produce NH4Ga(SO4)2, which was then converted into a precursor solution and spin-coated onto sapphire and quartz substrates. Ten cycles of spin coating produced smoother films, although higher annealing temperatures induced more cracks. The films on the (0001) sapphire subjected to spin-coating and preheating processes that were repeated for ten cycles, followed by annealing at 800 °C, had a preferred orientation in the [–201] direction. All the films showed high transmittances of 85% in ultraviolet–visible light with wavelengths above 400 nm. The films on the (0001) sapphire substrate that were annealed at 800 °C and 1000 °C exhibited bandgaps of 4.8 and 4.98 eV, respectively. The sapphire substrates demonstrated a superior compatibility for high-quality Ga2O3 film fabrication compared to quartz. This method offers a cost-effective and efficient approach for producing high-quality β-Ga2O3 films on high-temperature-resistant substrates with promising potential for optoelectronic applications.

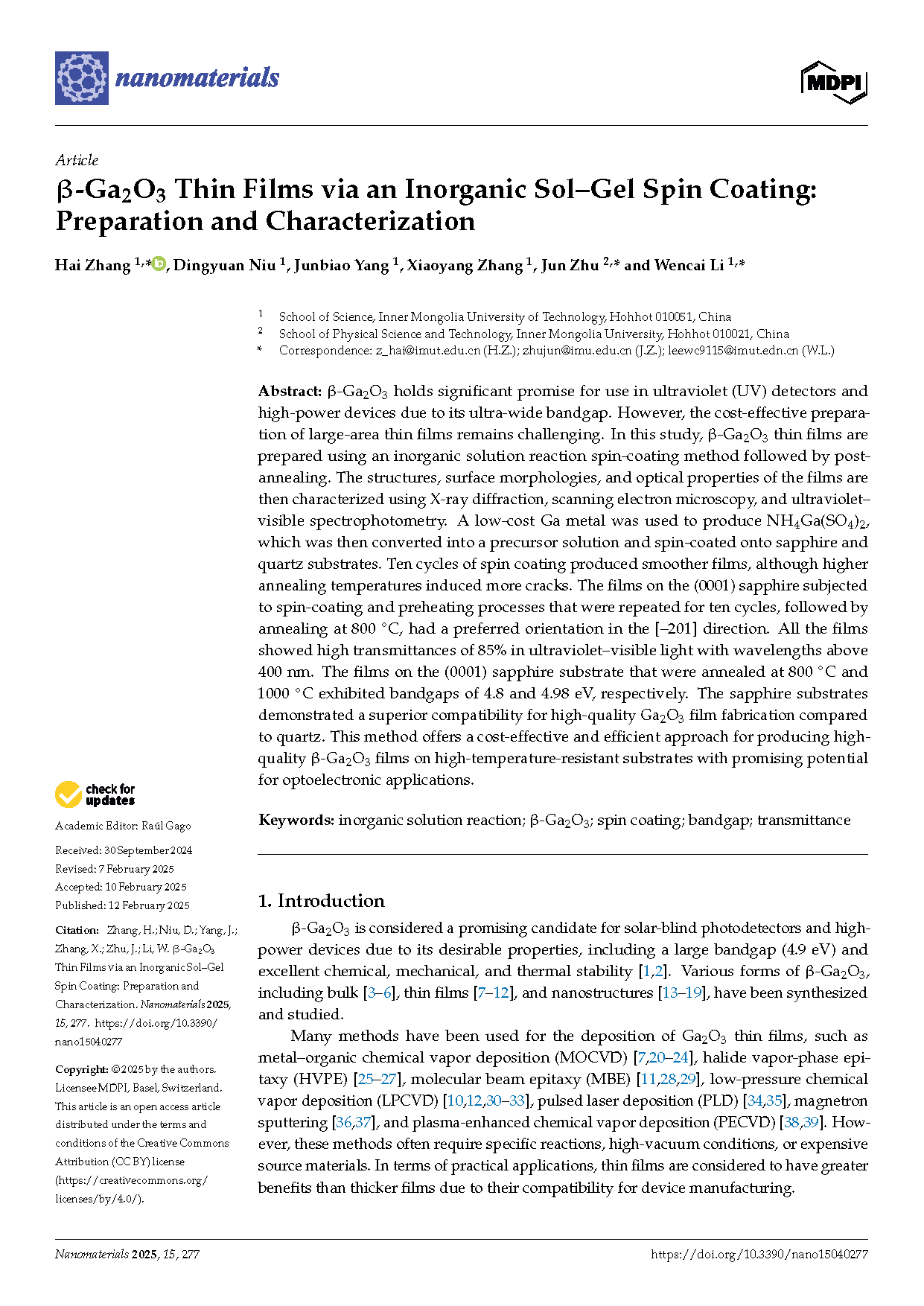

Figure 1. Schematic illustration of the Ga2O3 films prepared using the solution spin-coating method with a post-annealing process. Step (1): reaction between Ga and H2SO4. Step (2): repeated evaporation and filtration. Step (3): repeated evaporation and segregation to form NH4Ga(SO4)2·12H2O crystals. Step (4): evaporation, melting, and addition of an organic solvent to form the precursor solution. Step (5): spin coating of the solution on a substrate. Step (6): preheating at 150 °C. Step (7): spin-coating and preheating process consisting of 5–10 cycles. Step (8): post-annealing at 800–1000 °C to produce the final Ga2O3 film.

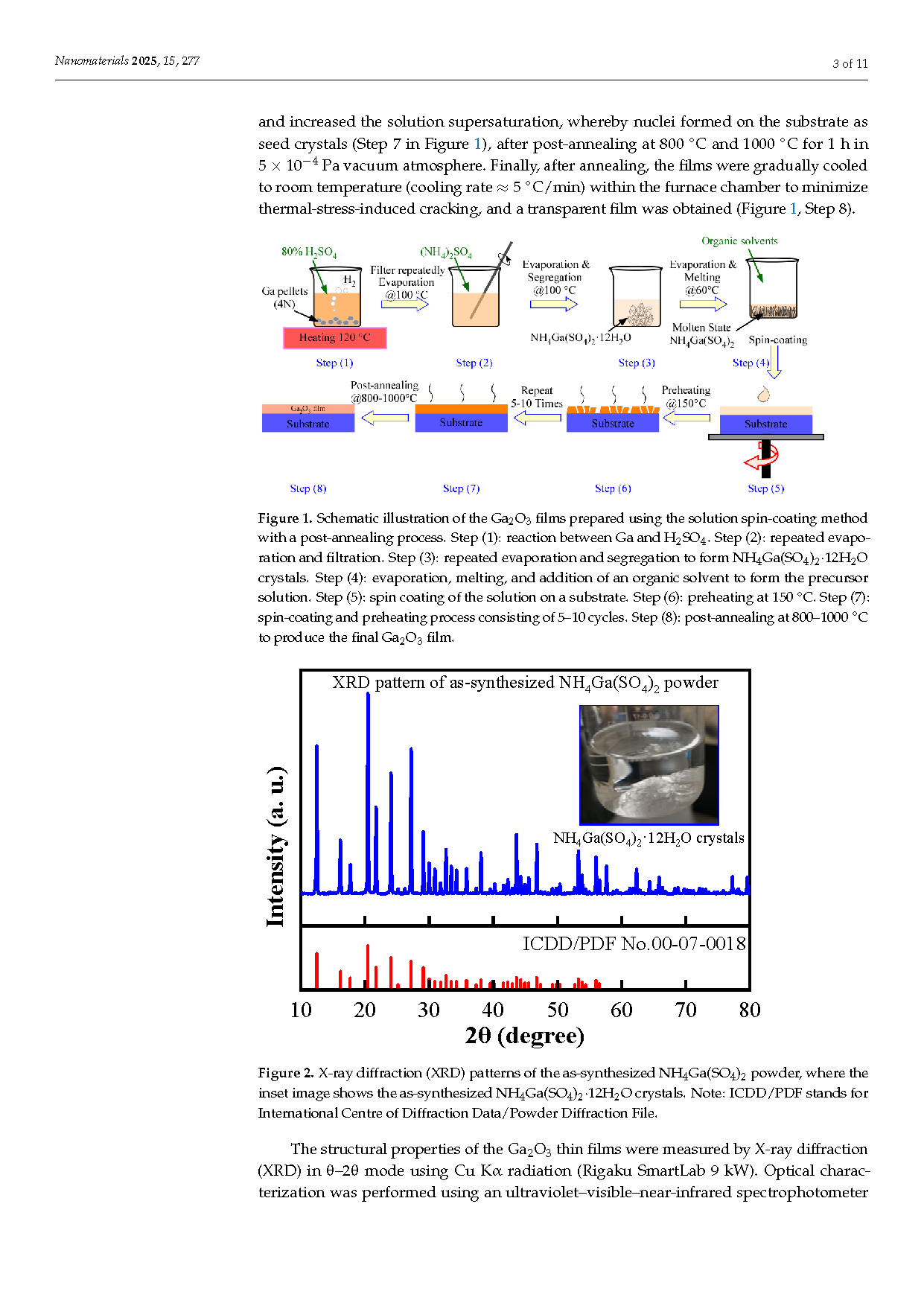

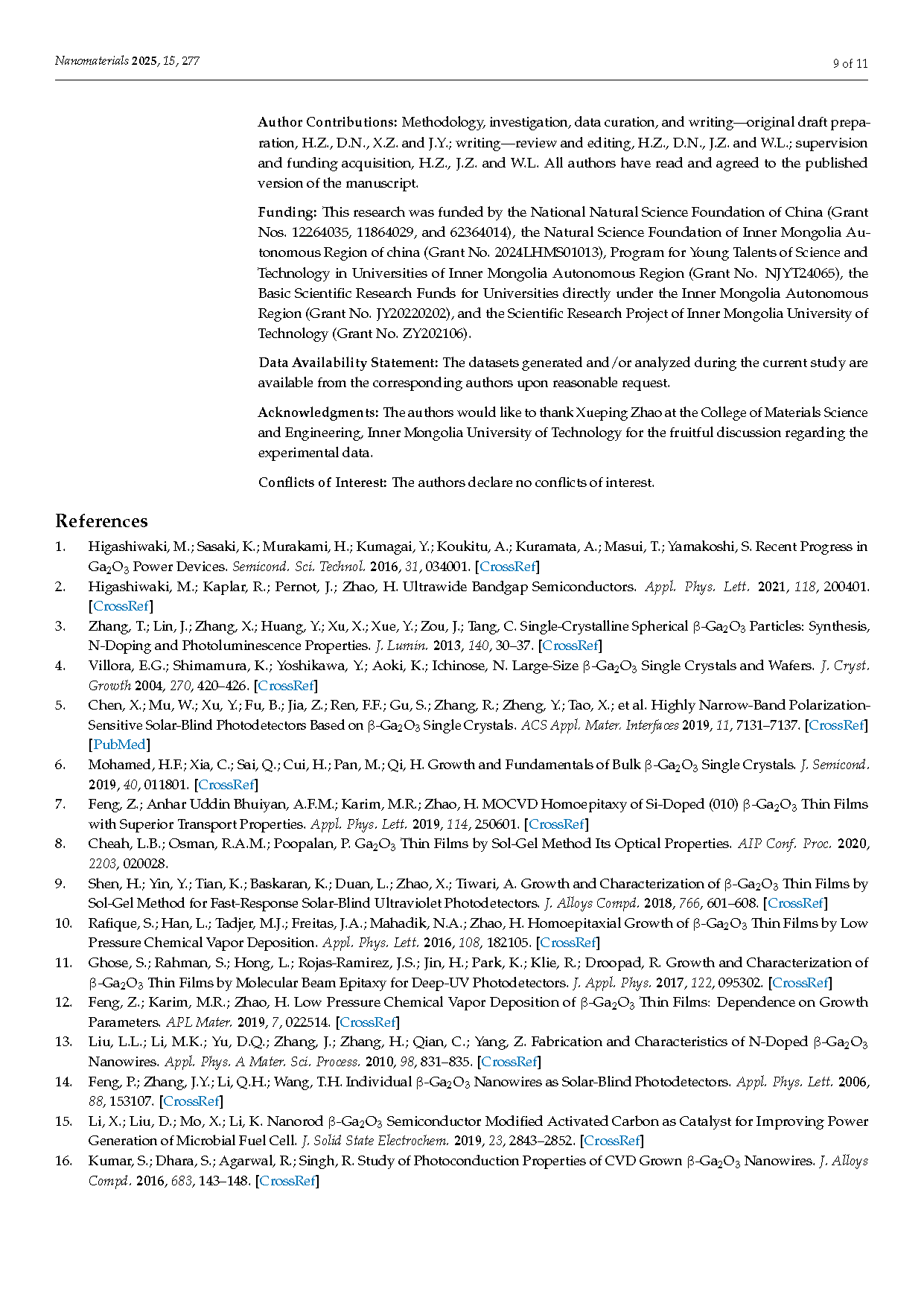

Figure 2. X-ray diffraction (XRD) patterns of the as-synthesized NH4Ga(SO4)2 powder, where the inset image shows the as-synthesized NH4Ga(SO4)2·12H2O crystals. Note: ICDD/PDF stands for International Centre of Diffraction Data/Powder Diffraction File.

DOI:

doi.org/10.3390/nano15040277