【International Papers】Epitaxial lateral overgrowth of m-plane α-Ga₂O₃ by halide vapor phase epitaxy

日期:2025-04-13阅读:483

Researchers from the National Institute for Materials Science have published a dissertation titled "Epitaxial lateral overgrowth of m-plane α-Ga2O3 by halide vapor phase epitaxy" in Science and Technology of Advanced Materials.

Background

Ga2O3 can crystallize to various polymorphs such as α-, β-, γ-, κ- (ε-), and δ-phases. Among them, the β-phase is the most thermodynamically stable under ambient pressure, whereas the others are metastable. Corundum-structured α-Ga2O3 is a metastable phase of Ga2O3, which is stable up to 500–700 °C (a thinner film exhibits higher thermal stability). This material is an ultra-wide-bandgap semiconductor with the highest bandgap energy (Eg = 5.3 eV) among the Ga2O3 polymorphs. In addition, it is possible to prepare solid solutions such as α-(AlGa)2O3 with other corundum-structured oxides over a wide composition range for band engineering or to impart new functionality. Furthermore, isomorphic p-type oxides with small lattice mismatches, such as α-(IrGa)2O3 are available to make a hetero pn-junction. Therefore, α-Ga2O3 is advantageous for realizing high-performance future power devices with high breakdown voltage (VB) and low energy loss. Indeed, promising device prototypes have been constructed, such as Schottky barrier diodes (SBDs) with a very-low on-resistance of 0.1 mΩcm2, ampere-class SBDs with a VB of 1.7 kV, and junction-barrier controlled SBDs with reduced leakage current. In addition, a demonstration of metal-oxide-semiconductor field-effect transistors has been reported.

Abstract

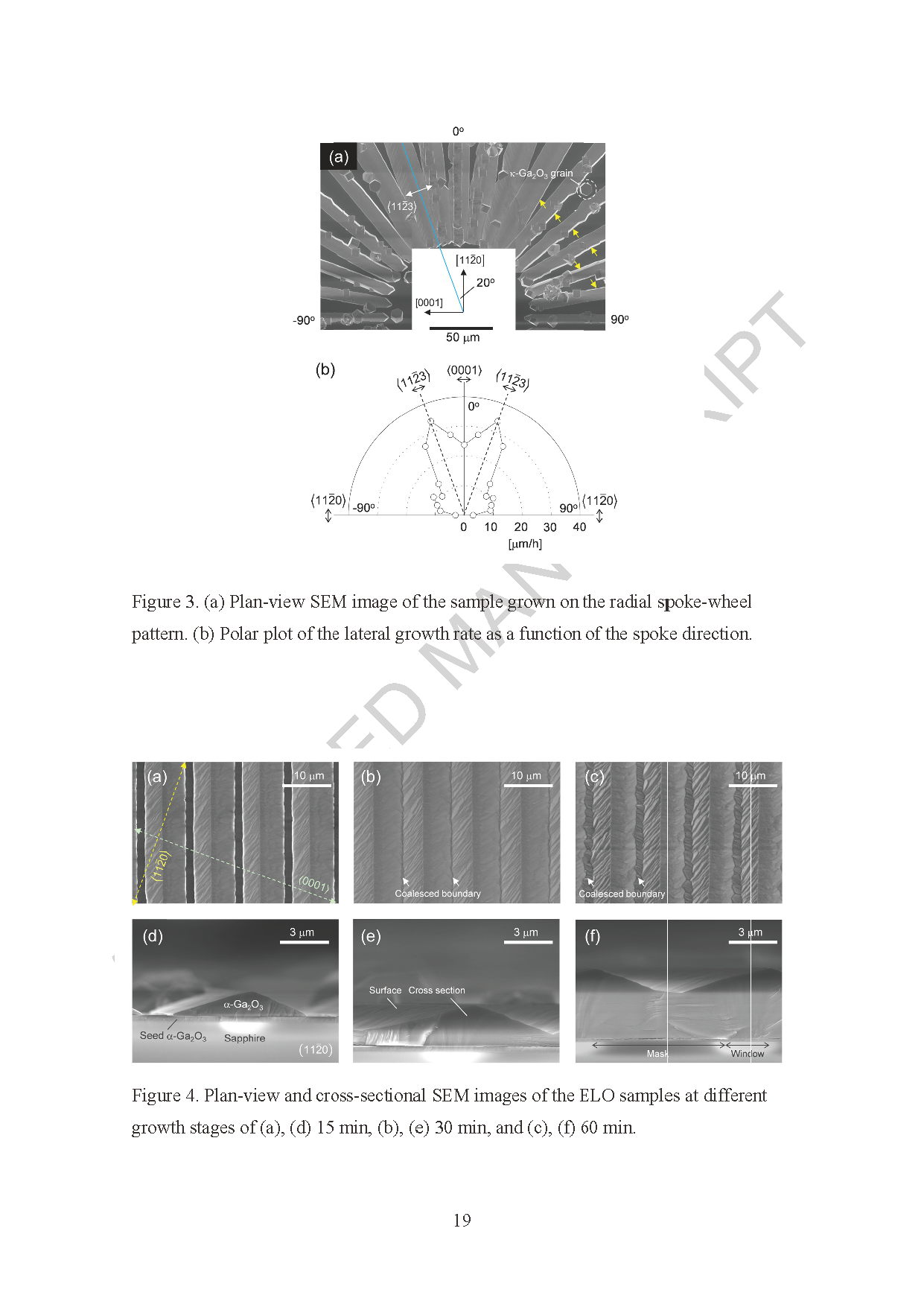

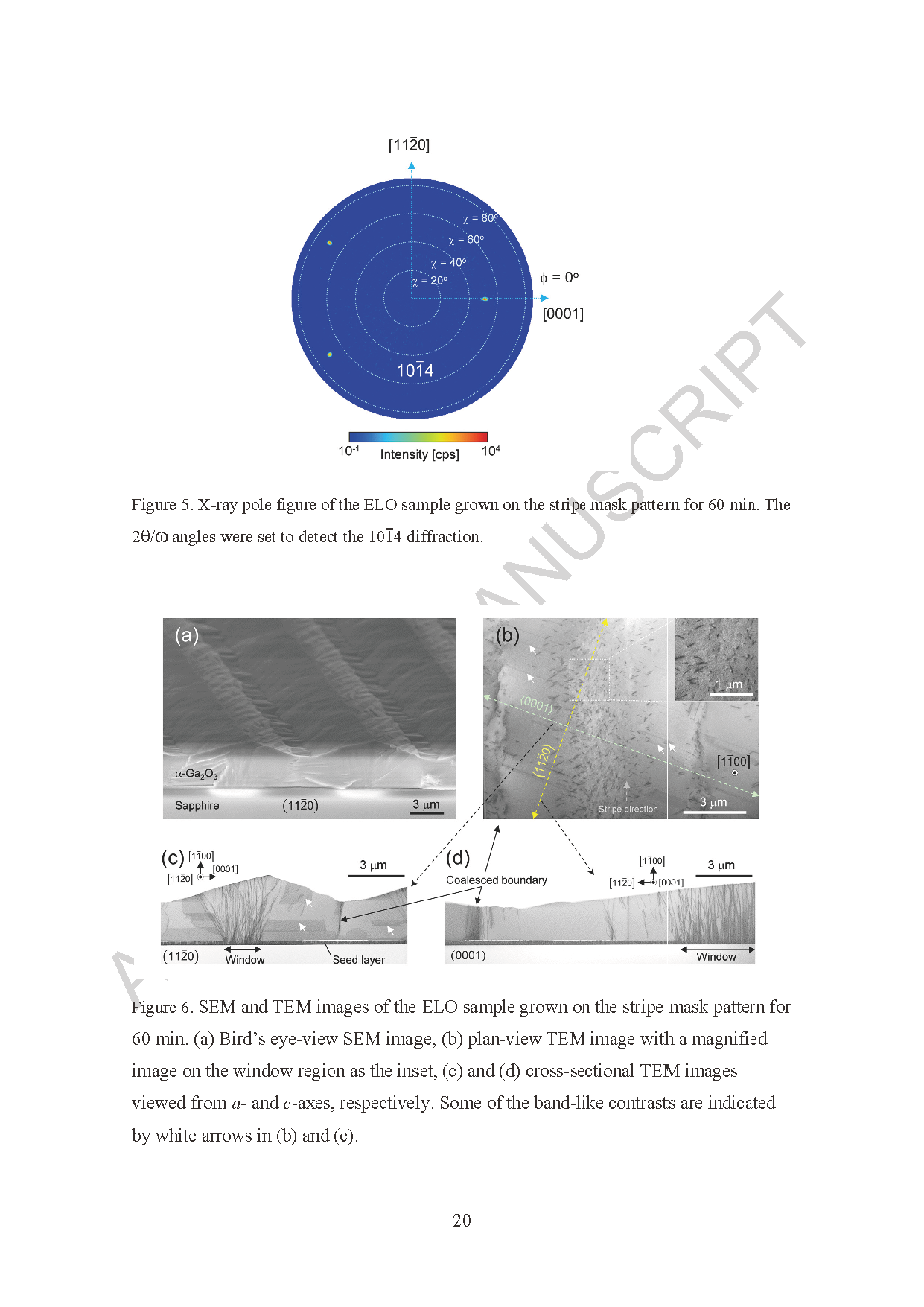

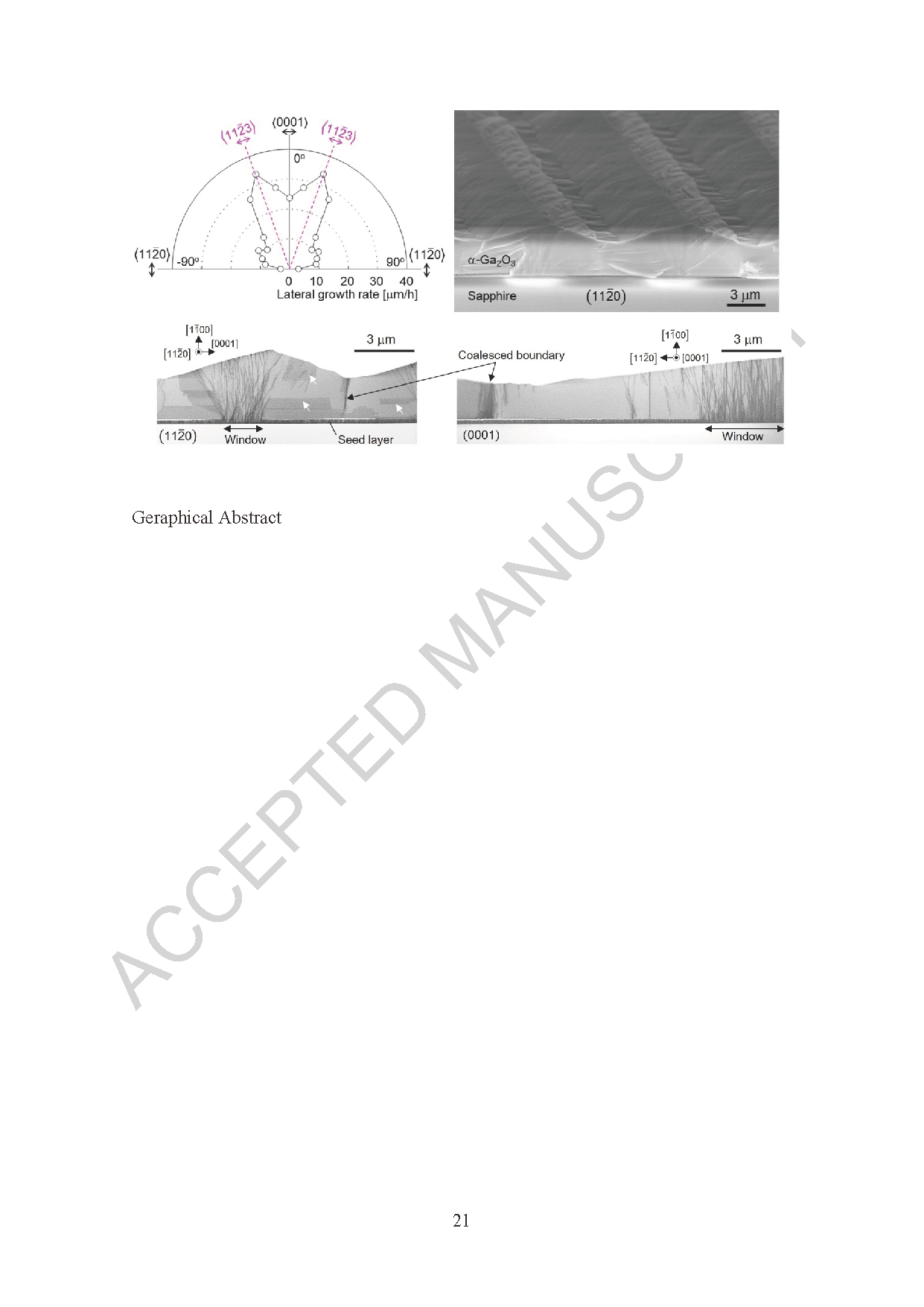

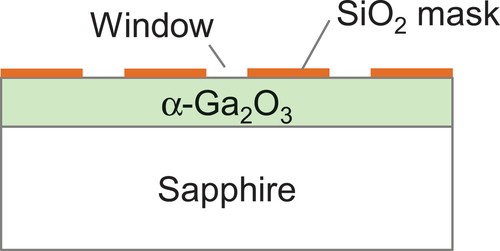

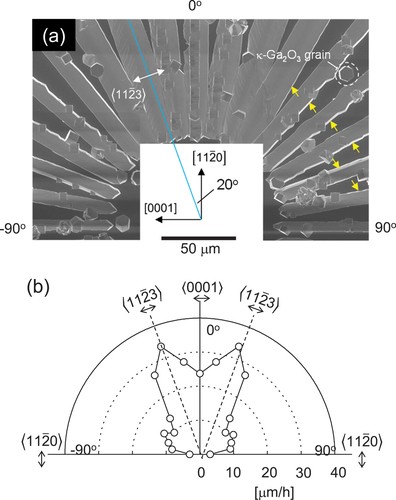

We demonstrated the epitaxial lateral overgrowth of m-plane α-Ga2O3 using halide vapor phase epitaxy. An m-plane α-Ga2O3/sapphire template with a patterned SiO2 mask was used as the substrate. The highest lateral growth rate for a radial spoke-wheel patterned mask was obtained when the spoke was perpendicular to the 11-23 direction. In this case, the lateral-to-vertical growth rate ratio (L/V ratio), with L defined as the rate of increase in the width of an elongated α-Ga2O3 island, was as large as 5.8. This ratio was greater than that reported for an m-direction stripe mask on a-plane α-Ga2O3 by a factor of 3.3 and that for an a-direction stripe mask on c- and m-plane α-Ga2O3 by a factor of 13. The epitaxial lateral overgrowth (ELO) of α-Ga2O3 on a stripe mask (window/mask widths of 2.5 μm/7.5 μm) perpendicular to (11-23) resulted in the selective nucleation of elongated α-Ga2O3 islands with a flat triangular cross-section on the window areas and their coalescence into a compact film. Transmission electron microscopy revealed that the dislocation density in the laterally grown area decreased drastically because the propagation of dislocations in the seed layer was effectively blocked by the mask. We believe these results greatly contribute to the realization of m-plane α-Ga2O3-based future power devices.

Summary

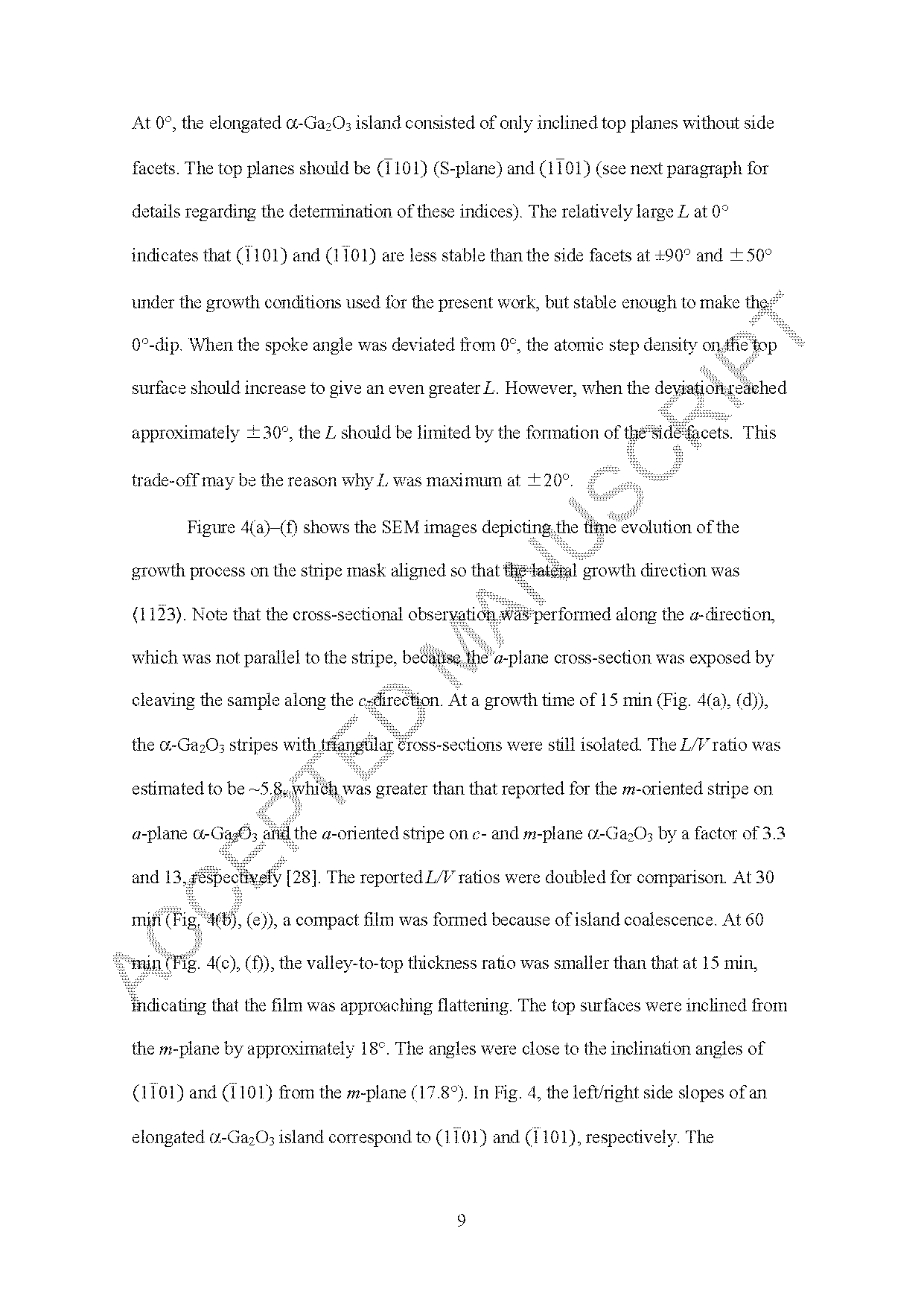

In this study, we demonstrated the ELO of α-Ga2O3 on the m-plane using HVPE. The anisotropy of the lateral growth rate was investigated using a radial-spoke-patterned mask, and the highest lateral growth rate was obtained along the ⟨11-23⟩ direction. Lateral growth rate L along ⟨11-23⟩ was 34 μm/h, which was approximately 11 times higher than that along ⟨11-20⟩, along which it was slowest. In the ⟨11-23⟩ case, the L/V ratio was 5.8, which was greater than the reported values for a-plane α-Ga2O3 with an m-direction stripe mask and m- and c-plane α-Ga2O3 with an a-direction stripe mask by a factor of 3.3 and 13, respectively. ELO was performed using the stripe mask pattern with window/mask widths of 2.5/7.5 μm aligned to give the highest lateral growth rate, and a compact film was achieved in <30 min. The plan-view and cross-sectional TEM images of the compact film revealed a significant reduction in the dislocation density in the laterally grown area although the dislocations propagated in the window area and were newly formed at the coalesced boundary. Planar defects were also observed in addition to dislocations. Thus, we believe that this technique will significantly contribute to the development of high-performance α-Ga2O3-based devices although the growth conditions require further improvement.

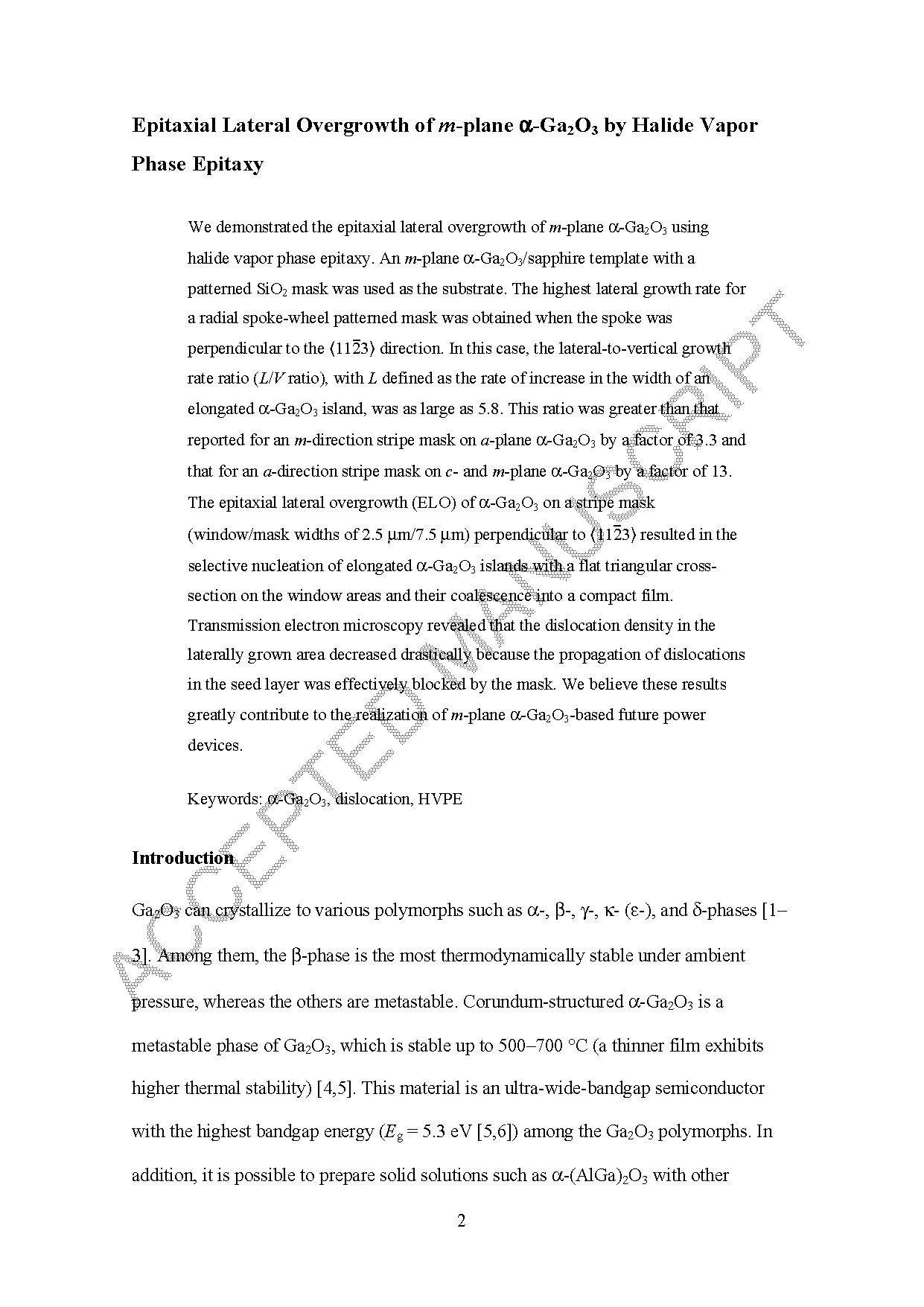

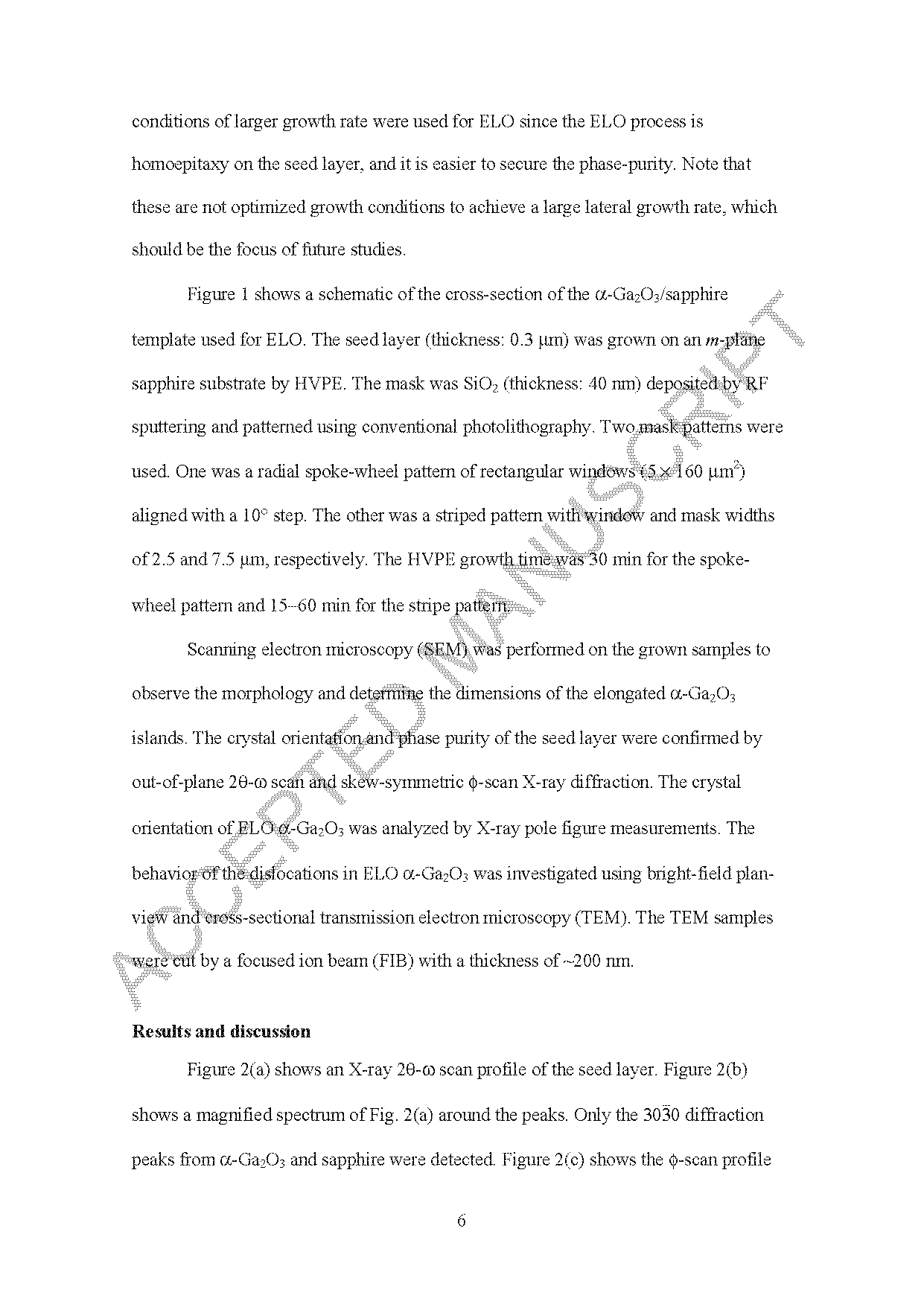

Figure 1. Schematic of the cross-section of an m-plane α-Ga2O3/sapphire template with a patterned mask.

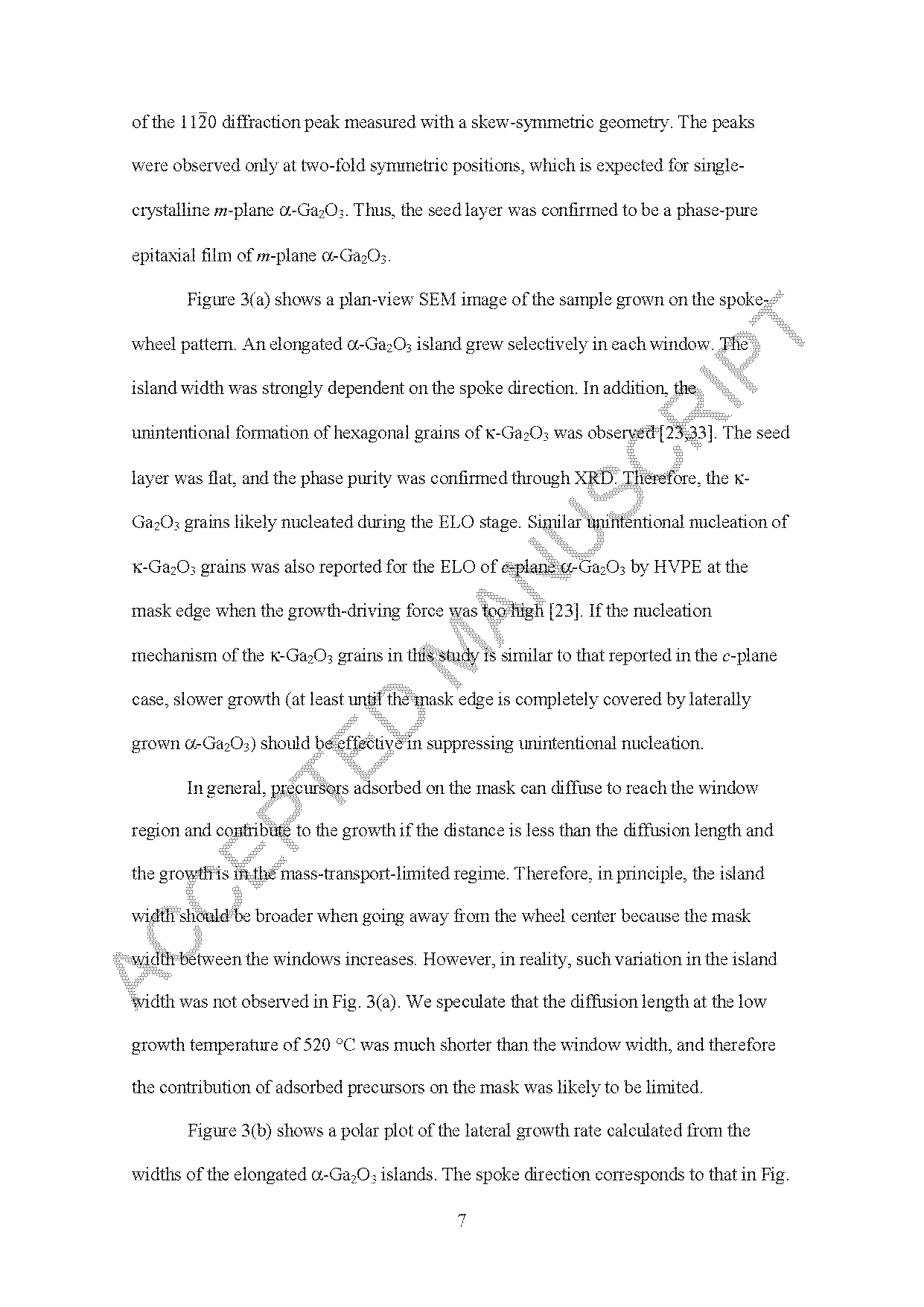

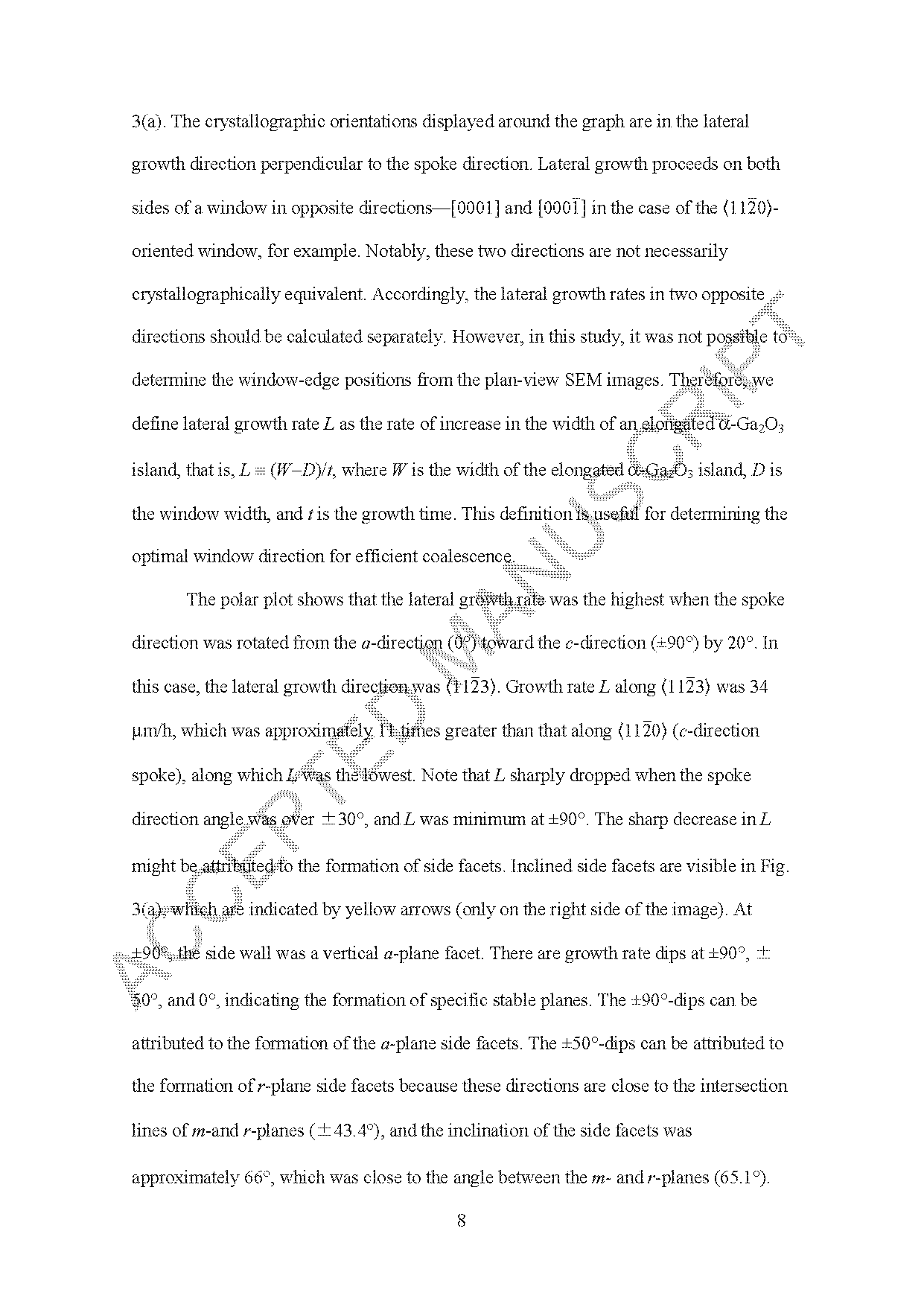

Figure 2. (a) Plan-view SEM image of the sample grown on the radial spoke-wheel pattern. (b) Polar plot of the lateral growth rate as a function of the spoke direction.

DOI:

doi.org/10.1080/14686996.2025.2485869