【Member Papers】Southern University of Science and Technology --- Investigation of the machinability of (001) single-crystal β-Ga₂O₃ via tribological methodology

日期:2025-04-14阅读:495

Researchers from the Southern University of Science and Technology have published a dissertation titled "Investigation of the machinability of (001) single-crystal β-Ga2O3 via tribological methodology" in Nanotechnology and Precision Engineering.

Acknowlegement

The authors acknowledge financial support from the Shenzhen Key Laboratory of Intelligent Robotics Flexible and Manufacturing Systems (Grant No. ZDSYS20220527171403009) and the Shenzhen Science and Technology Innovation Commission (Grant No. 20231115111658002). Special thanks to SUSTech Core Research Facilities and the SUSTech Energy Research Institute for Carbon Neutrality for their valuable technical support.

Abstract

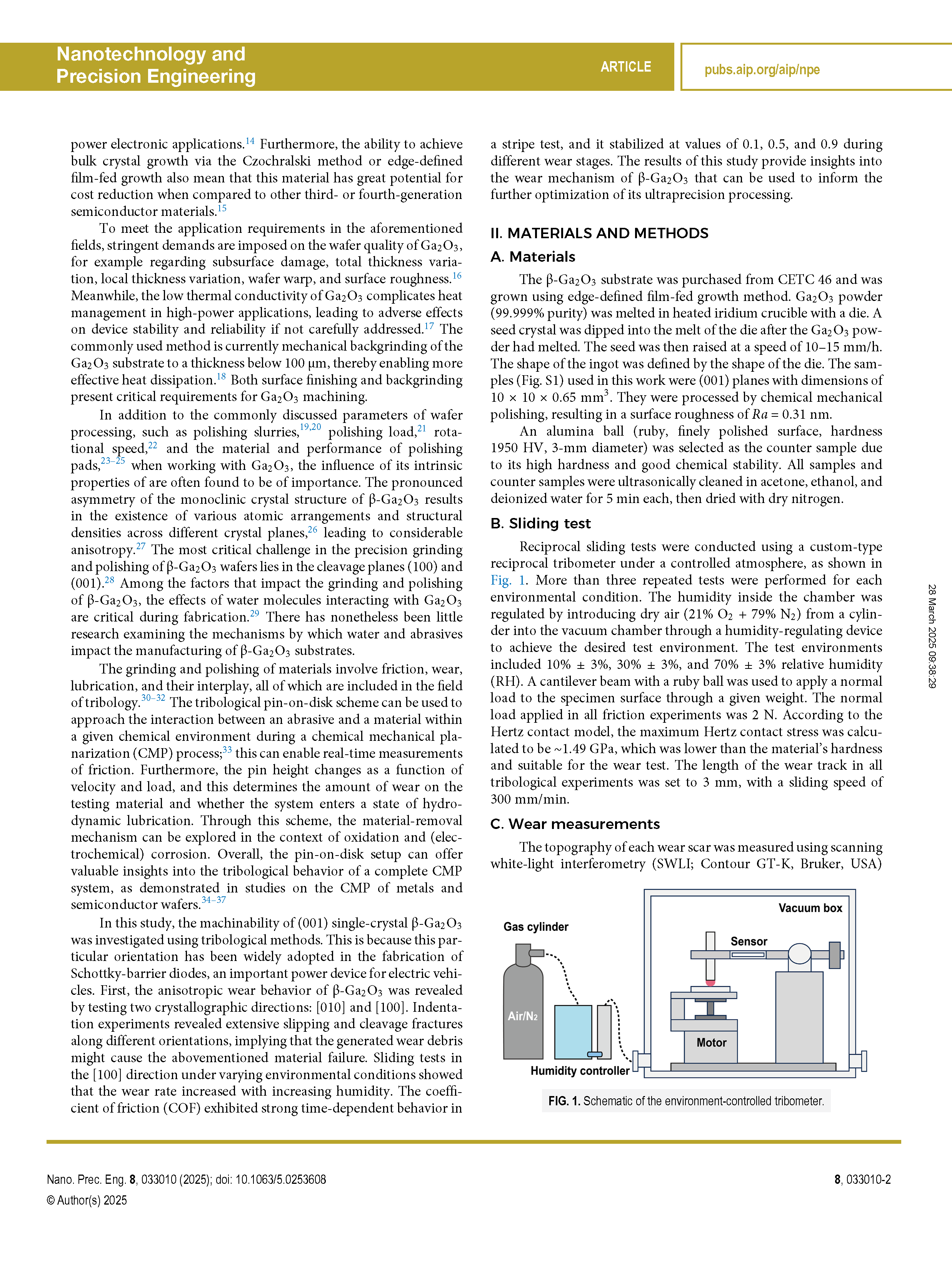

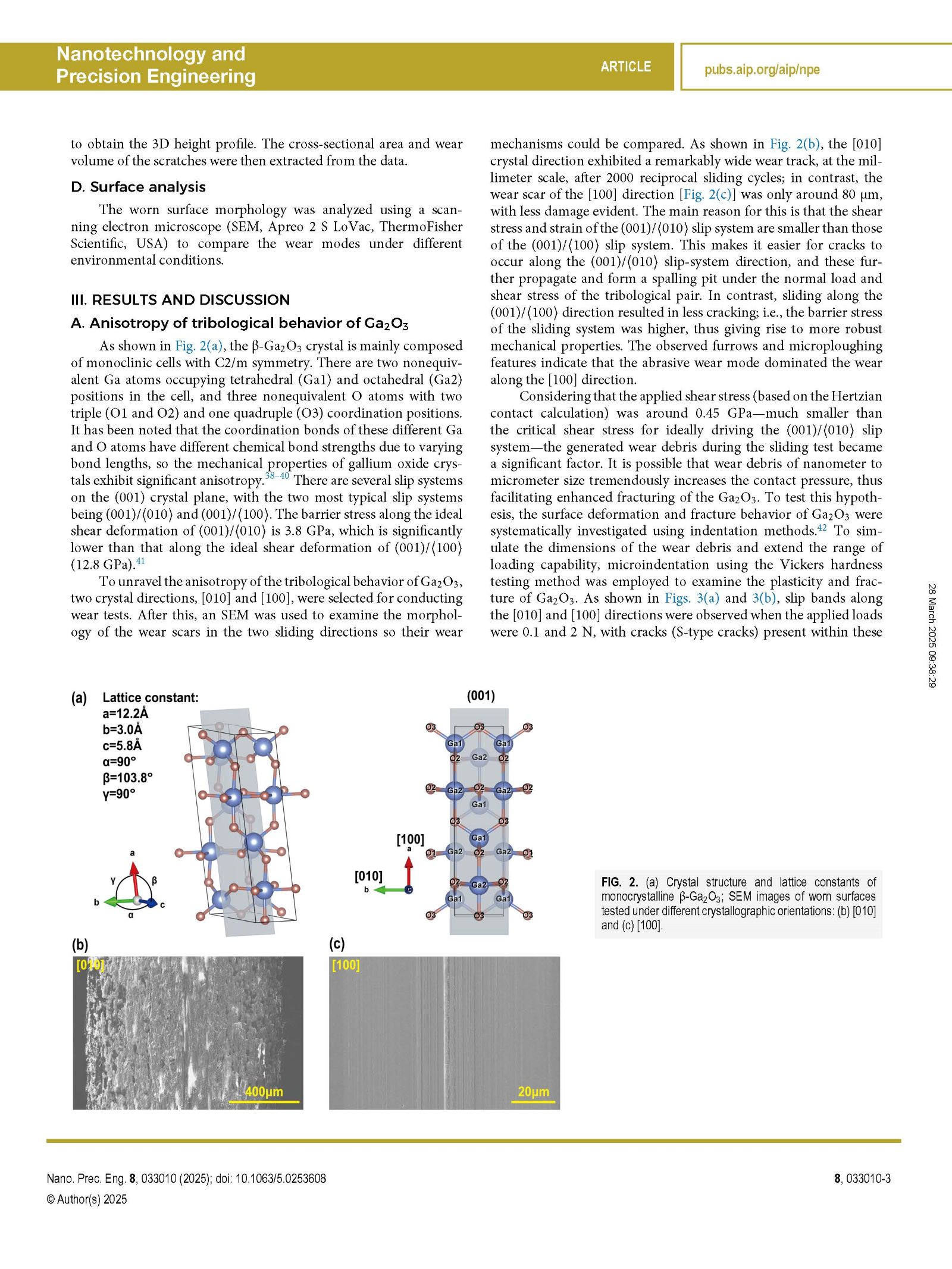

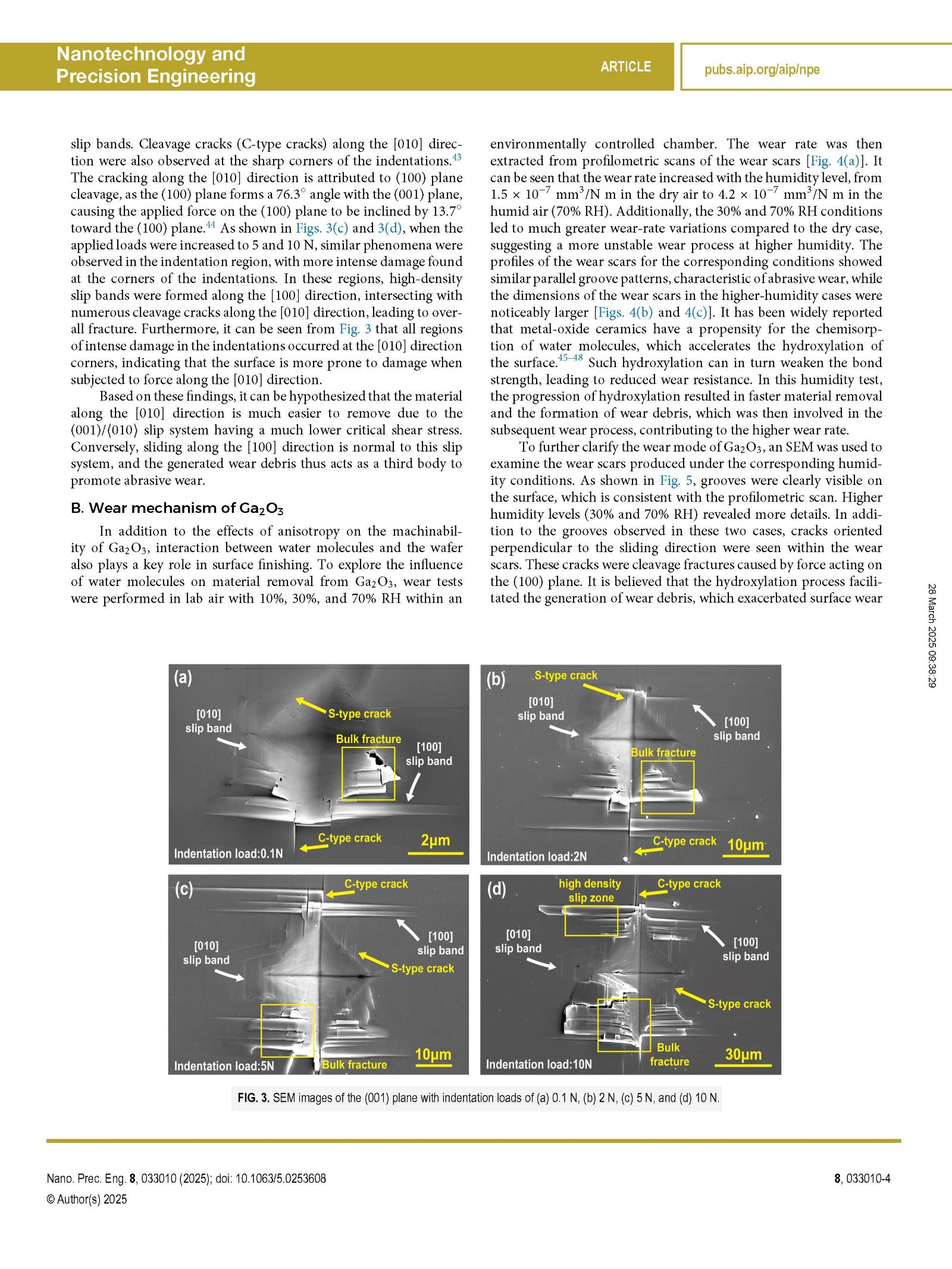

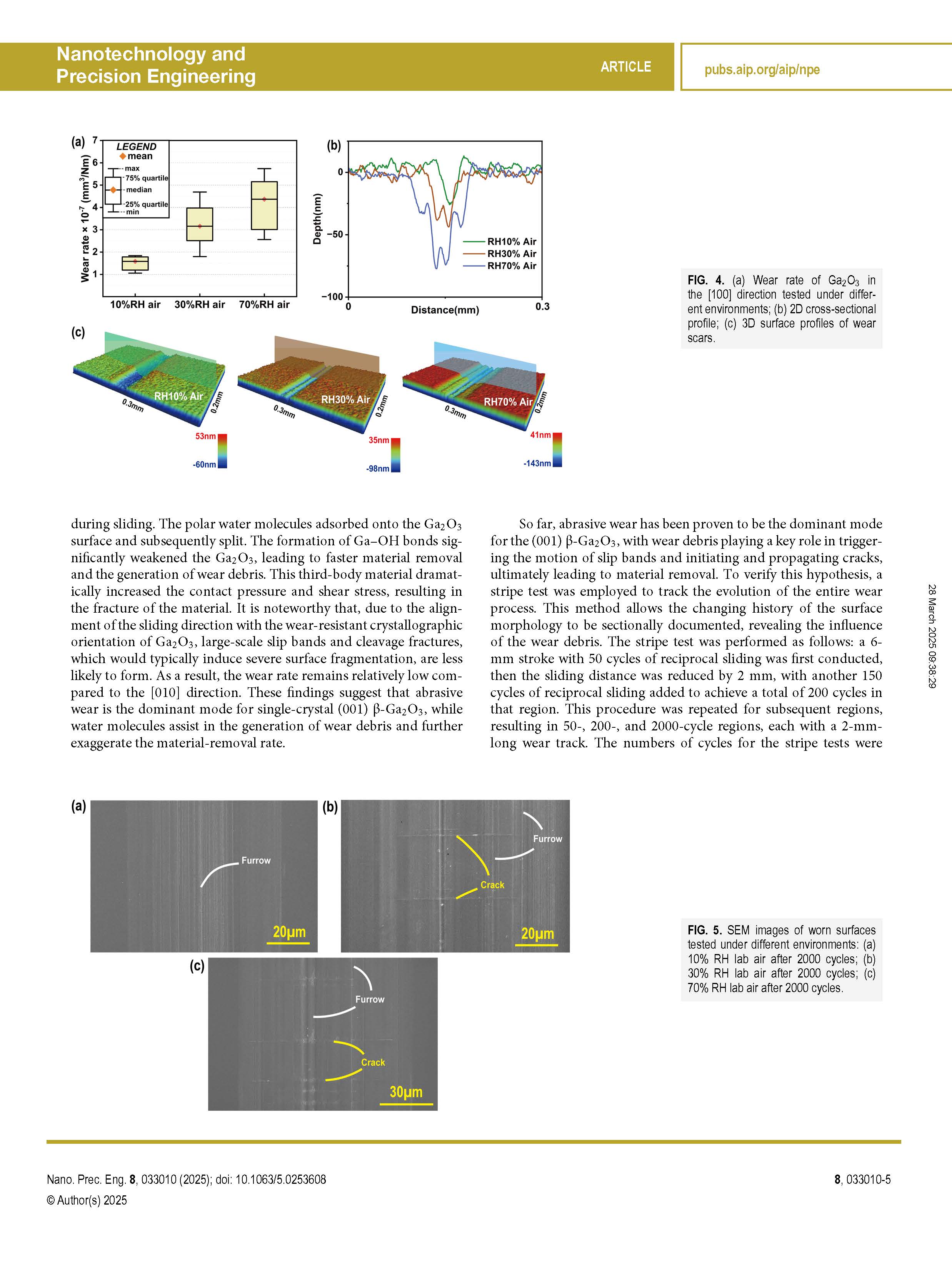

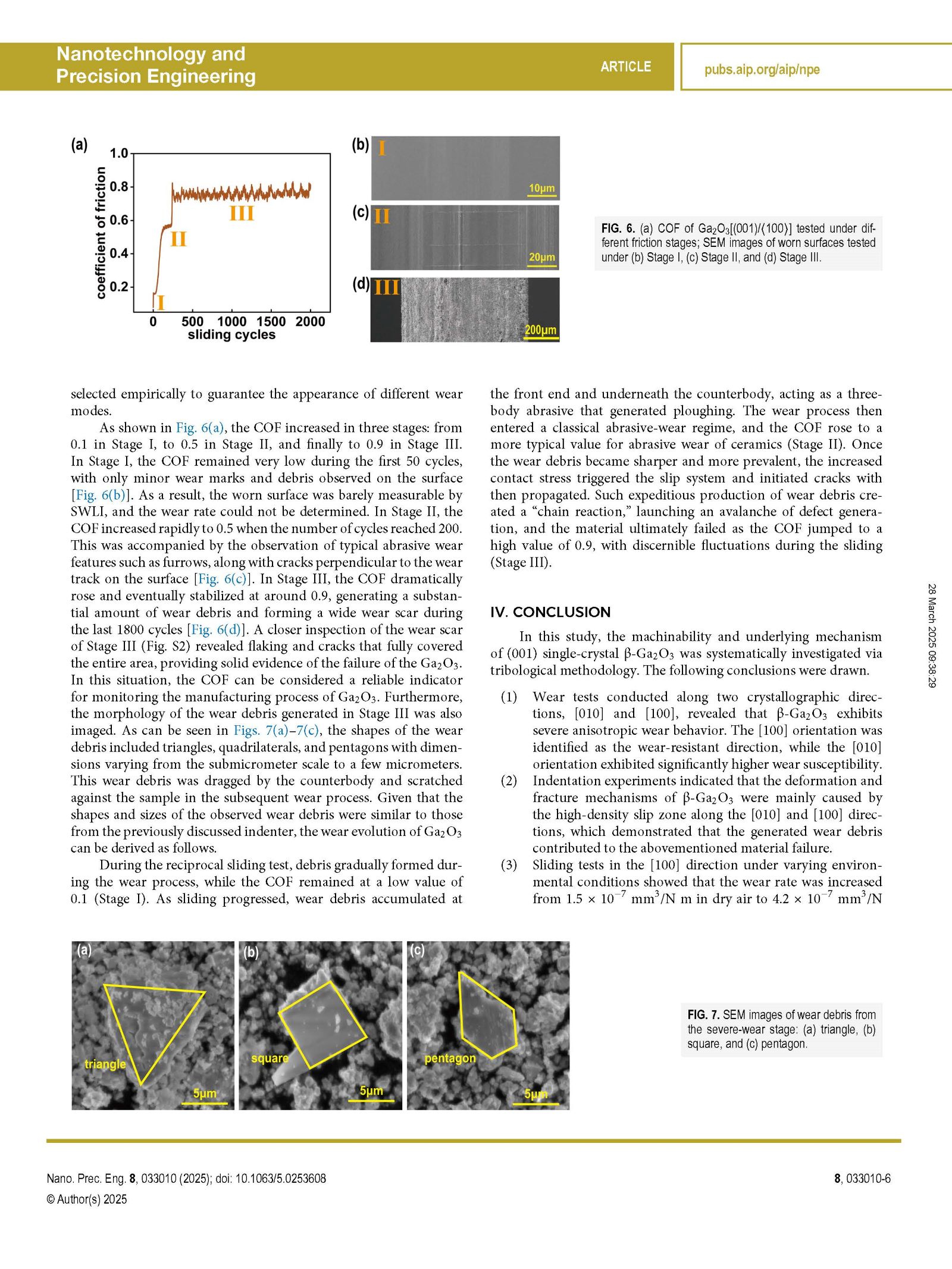

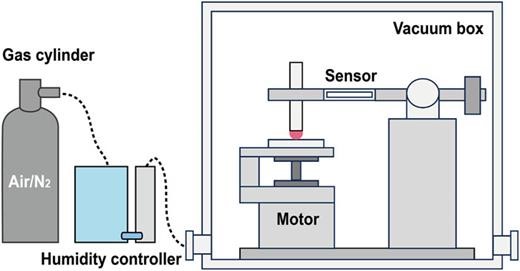

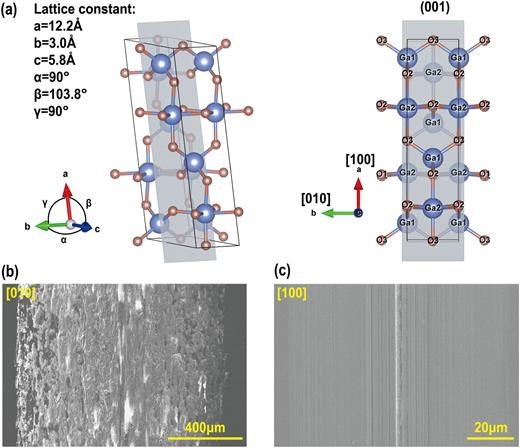

Gallium oxide (Ga2O3) is a promising material for next-generation power devices due to its ultrawide bandgap and extremely high critical electric field strength; however, the strong anisotropy and cleavage tendency of Ga2O3 pose significant challenges for high-precision surface processing. In this work, a systematic study was conducted through tribological analysis of monocrystalline (001) β-Ga2O3. Initially, reciprocal sliding tests were conducted on β-Ga2O3 along different crystallographic directions, [100] and [010]. The results revealed that the [100] direction was more wear resistant, while the [010] direction was more prone to failure. Indentation experiments on (001) β-Ga2O3 showed extensive slip and cleavage cracking along different crystallographic orientations, indicating that mechanical wear might dominate the wear mode of this material. Subsequently, sliding tests under various environmental conditions revealed that the wear rate was correlated with humidity. Additionally, β-Ga2O3 exhibited time-dependent frictional behavior, with its coefficient of friction stabilizing around 0.1, 0.5, and 0.9 at different stages during the wear test. These findings indicate that the frictional behavior of Ga2O3 is closely linked to the state of its surface. This study provides critical insights into the tribological behavior of Ga2O3 and offers guidance for ultraprecision machining of this material.

Conclusion

In this study, the machinability and underlying mechanism of (001) single-crystal β-Ga2O3 was systematically investigated via tribological methodology. The following conclusions were drawn.

1.Wear tests conducted along two crystallographic directions, [010] and [100], revealed that β-Ga2O3 exhibits severe anisotropic wear behavior. The [100] orientation was identified as the wear-resistant direction, while the [010] orientation exhibited significantly higher wear susceptibility.

2.Indentation experiments indicated that the deformation and fracture mechanisms of β-Ga2O3 were mainly caused by the high-density slip zone along the [010] and [100] directions, which demonstrated that the generated wear debris contributed to the abovementioned material failure.

3.Sliding tests in the [100] direction under varying environmental conditions showed that the wear rate was increased from 1.5 × 10−7 mm3/N m in dry air to 4.2 × 10−7 mm3/N m in humid air (70% RH). This increase in wear rate was attributed to the application of shear stress at the interface between water and β-Ga2O3, which promoted the formation of hydroxides that were easily removed as wear debris.

4.The COF of β-Ga2O3 exhibited sliding-cycle-dependent behavior in the stripe test, with values stabilizing at ∼0.1, 0.5, and 0.9 at different wear stages. The wear process progressed through three stages: it began with mild abrasive wear and a low COF, then transitioned to more intense material failure due to a “chain reaction” of wear debris accumulation and crack propagation, resulting in a significant increase in COF.

These insights enhance the understanding of the wear mechanisms of β-Ga2O3 and provide valuable guidance for optimizing processing parameters such as applied load, rotation speed, and abrasive slurry, thus improving the surface finishing quality of (001) single-crystal β-Ga2O3.

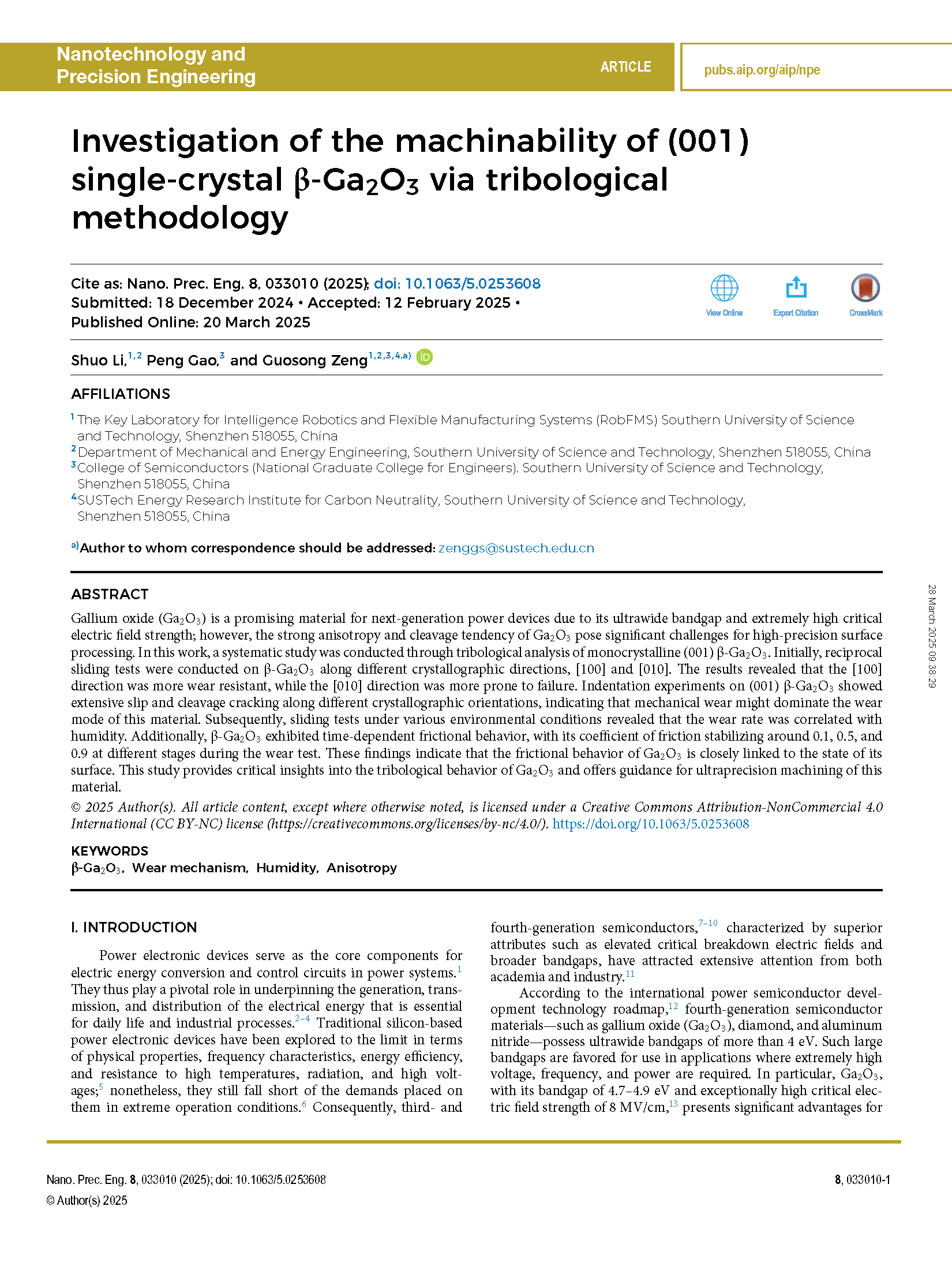

FIG. 1. Schematic of the environment-controlled tribometer.

FIG. 2. (a) Crystal structure and lattice constants of monocrystalline β-Ga2O3; SEM images of worn surfaces tested under different crystallographic orientations: (b) [010] and (c) [100].

DOI:

doi.org/10.1063/5.0253608