【International Papers】Indentation-induced formation of vacancy defects in β-Ga₂O₃ crystals

日期:2025-08-29阅读:390

Researchers from the University of Technology Sydney have published a dissertation titled "Indentation-induced formation of vacancy defects in β-Ga2O3 crystals" in Applied Surface Science.

Abstract

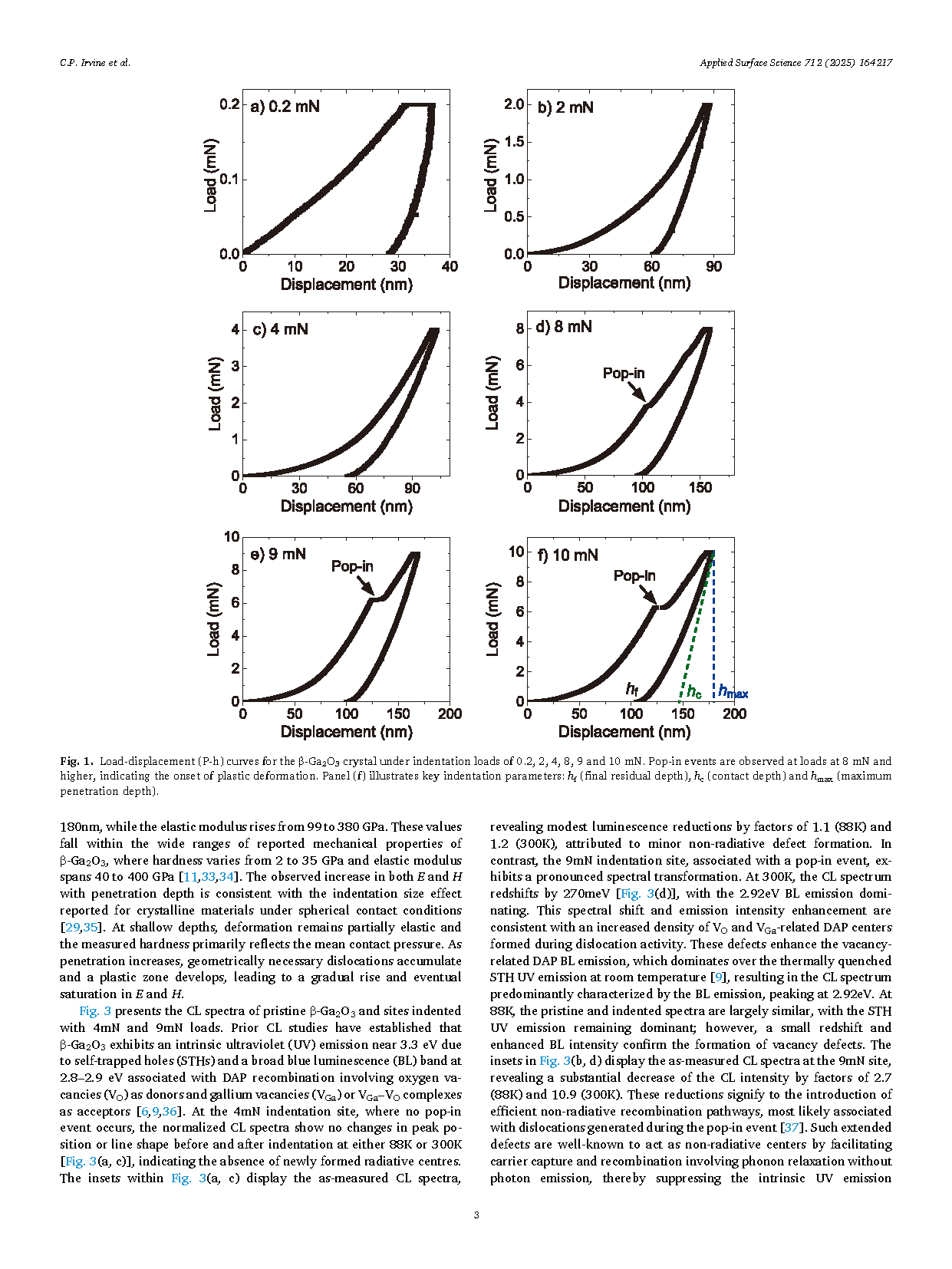

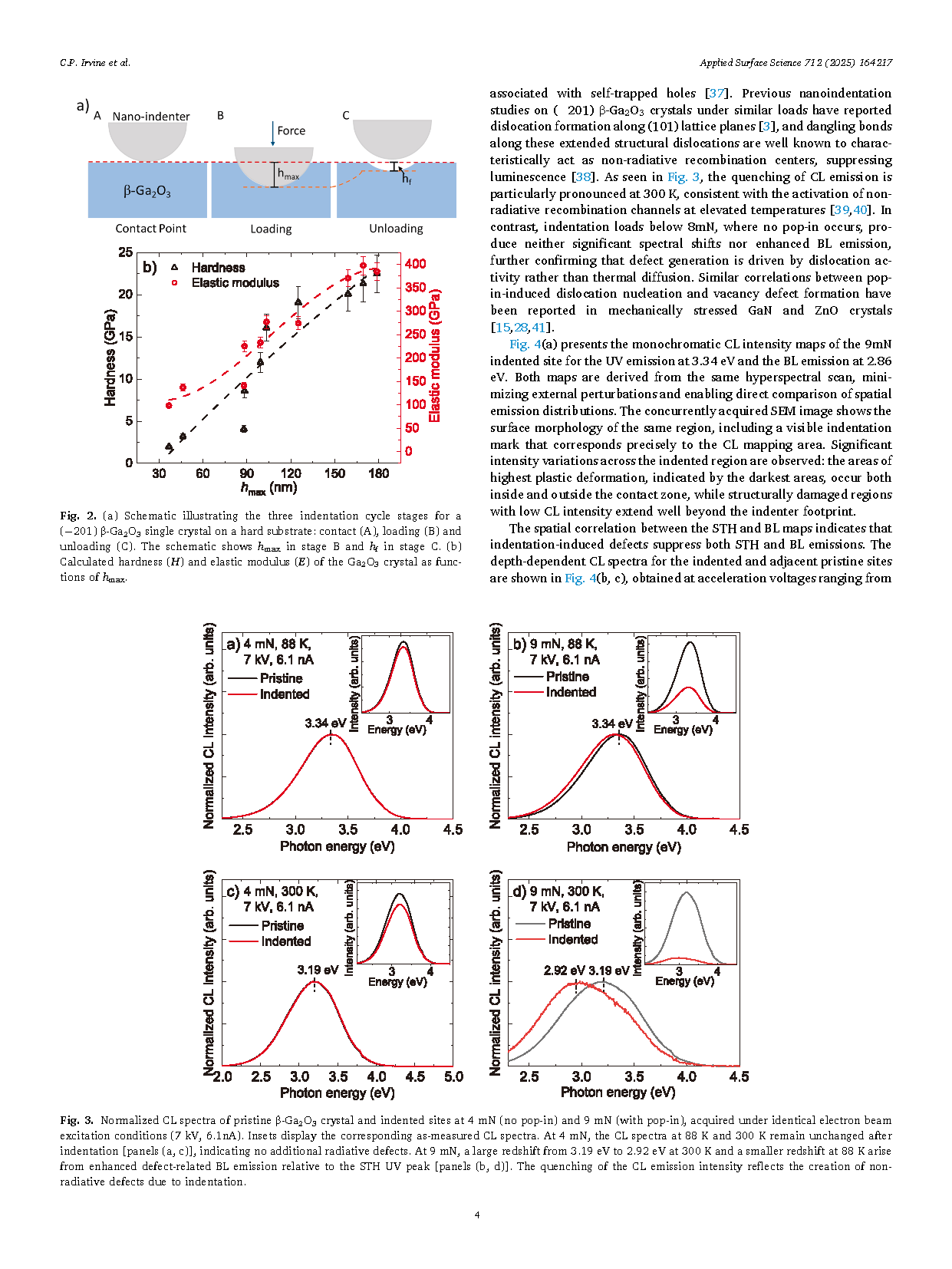

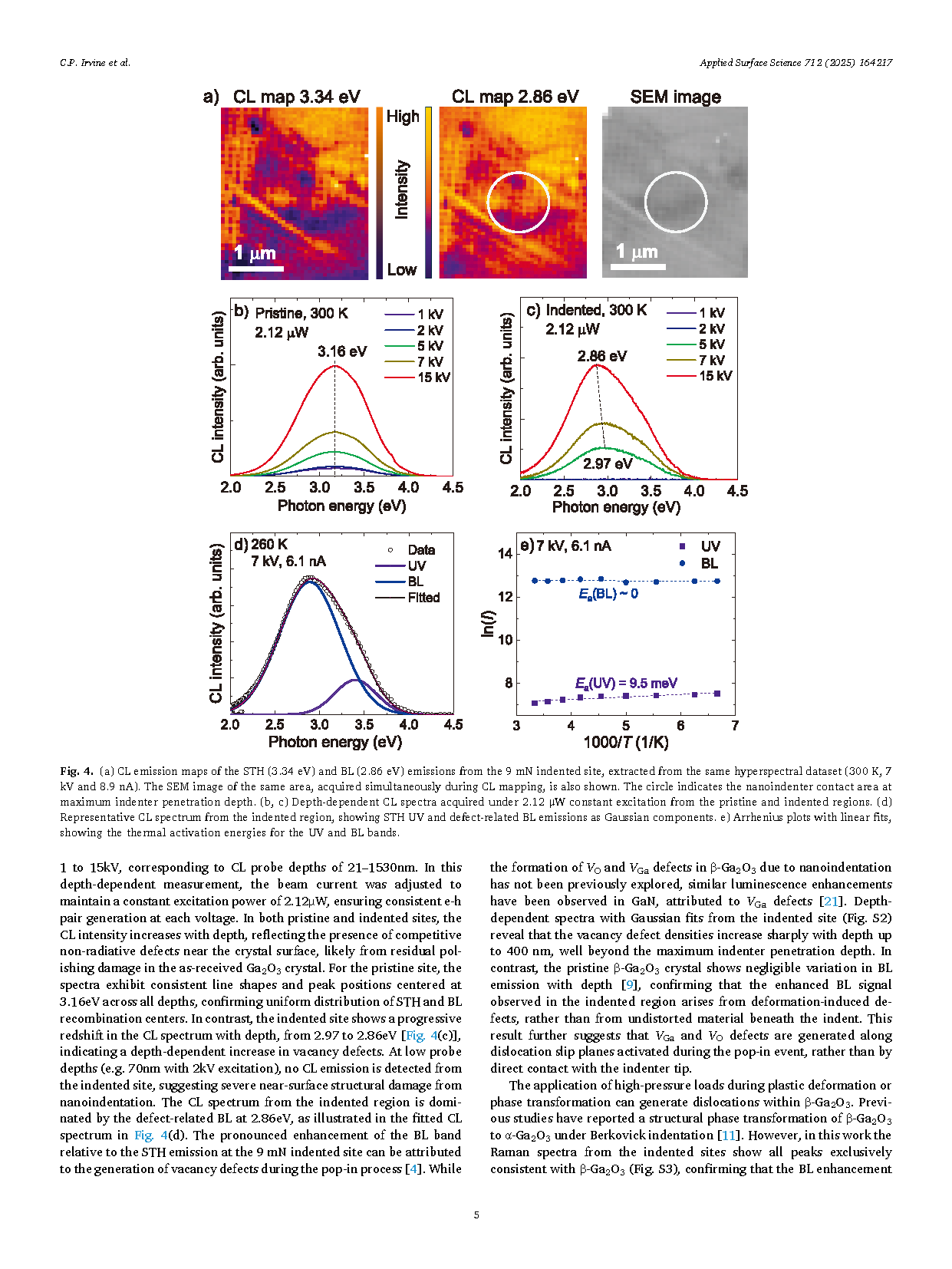

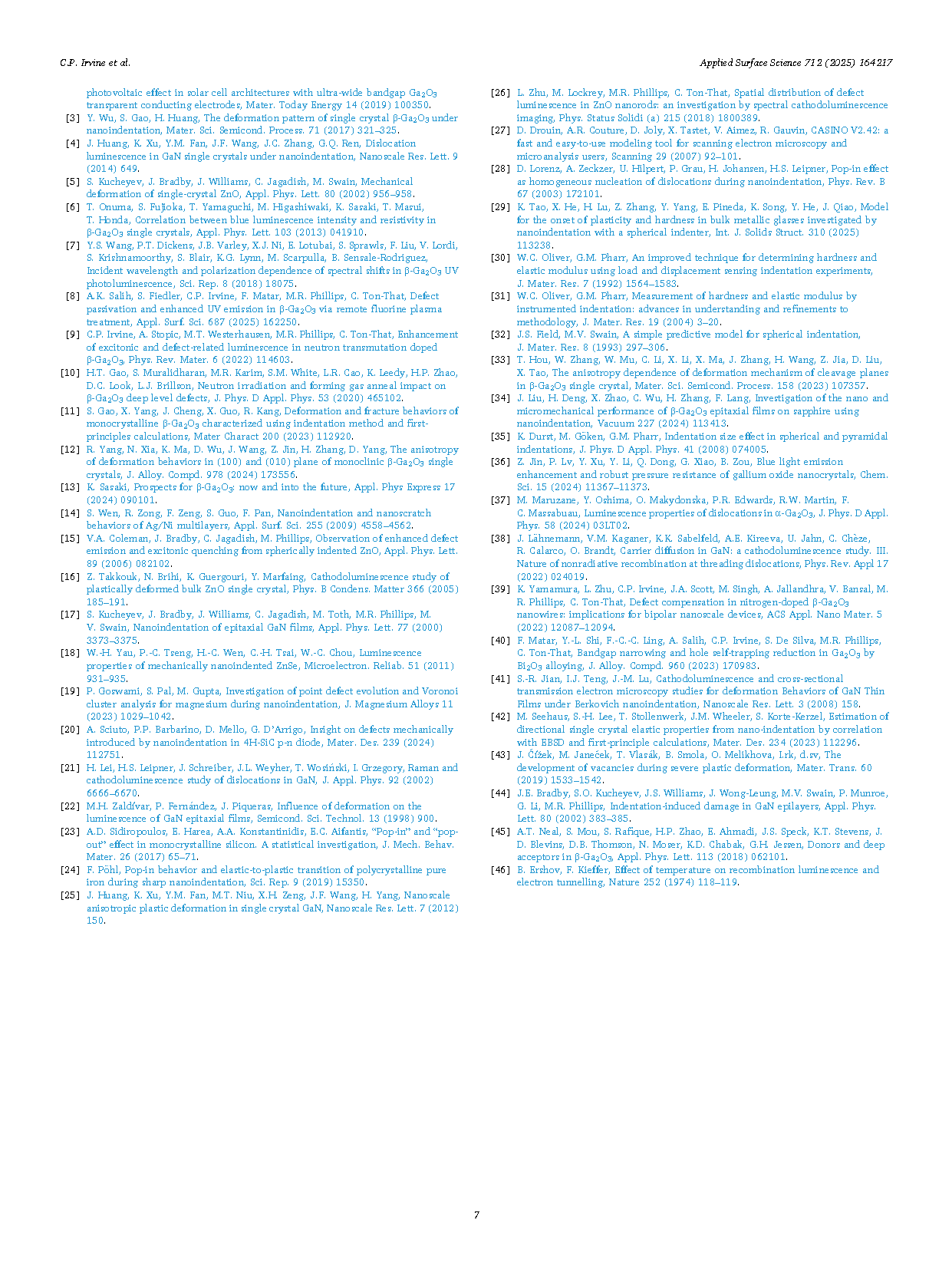

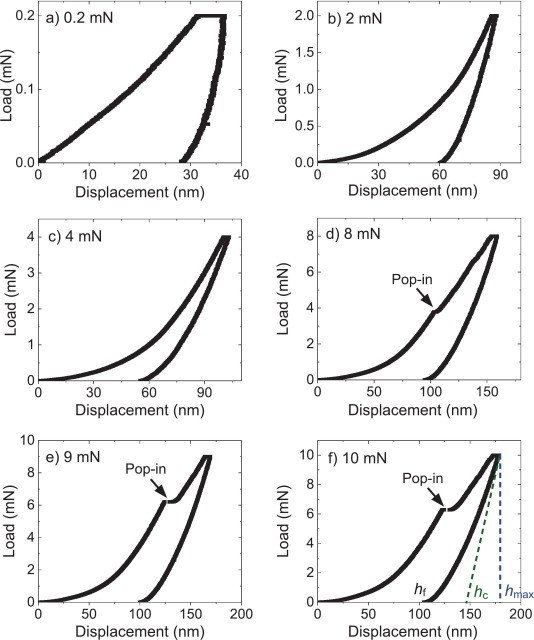

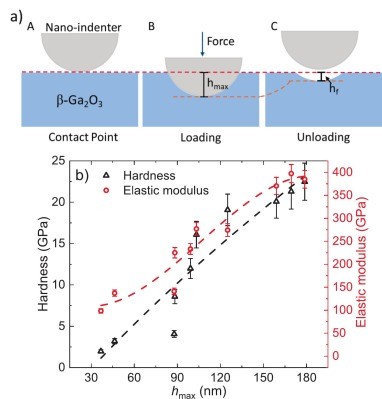

This study investigates the near-surface mechanical behavior and defect formation in (−201) β-Ga2O3 crystals subjected to spherical nanoindentation. Nanoindentation load-displacement measurements identify pop-in events at applied loads of 8 mN or higher, marking the onset of elastic-plastic deformation. Mechanical characterisation provides depth-dependent hardness and Young’s modulus values, ranging from 2 to 23 GPa and from 99 to 380 GPa, respectively. Cathodoluminescence (CL) spectroscopy shows a 270 meV redshift and intensity enhancement of blue luminescence (BL) due to donor–acceptor pair (DAP) transitions involving oxygen vacancies (VO) and gallium vacancy (VGa or VO-VGa complexes), accompanied by strong quenching of the intrinsic UV emission associated with self-trapped holes. These spectral changes are attributed to the formation of vacancy defects and extended non-radiative recombination centers during the pop-in event. Depth-resolved CL spectroscopy and spectral mapping reveal that these defects extend well beyond the indenter contact zone, while complementary electron backscatter diffraction (EBSD) mapping confirms localized plastic deformation and dislocation activity around the indent perimeter. The findings provide direct evidence that dislocation motion under mechanical stress generates both radiative and non-radiative defects in β-Ga2O3, highlighting its susceptibility to mechanical damage in optoelectronic and power electronic devices.

Highlights

● Spherical nanoindentation of (−201) β-Ga2O3 induces vacancy defects.

● Vacancy-related blue luminescence increases due to donor–acceptor pair formation.

● Cathodoluminescence and EBSD reveal defect propagation beyond the contact zone.

● Indentation-induced dislocations act as non-radiative centers, quenching UV emission.

● Findings highlight susceptibility of β-Ga2O3 to mechanical damage in electronics.

Fig. 1. Load-displacement (P-h) curves for the β-Ga2O3 crystal under indentation loads of 0.2, 2, 4, 8, 9 and 10 mN. Pop-in events are observed at loads at 8 mN and higher, indicating the onset of plastic deformation. Panel (f) illustrates key indentation parameters: hf (final residual depth), hc (contact depth) and hmax (maximum penetration depth).

Fig. 2. (a) Schematic illustrating the three indentation cycle stages for a (−201) β-Ga2O3 single crystal on a hard substrate: contact (A), loading (B) and unloading (C). The schematic shows hmax in stage B and hf in stage C. (b) Calculated hardness (H) and elastic modulus (E) of the Ga2O3 crystal as functions of hmax.

DOI:

doi.org/10.1016/j.apsusc.2025.164217