【Member Papers】Effect of argon-oxygen ratios on crystallization and surface morphology of gallium oxide thin films by low-pressure chemical vapor deposition

日期:2025-11-05阅读:268

Researchers from the Xi’an University of Technology have published a dissertation titled "Effect of argon-oxygen ratios on crystallization and surface morphology of gallium oxide thin films by low-pressure chemical vapor deposition" in 2025 IEEE Workshop on Wide Bandgap Power Devices and Applications in Asia (WiPDA Asia) .

Project Support

This work was supported by the National Natural Science Foundation of China (Grant No.62474139 and 61904146); Science and technology planning project of Xi'an (No.2023JH-GXRC-0122).

Background

Boasting an ultra-wide bandgap (4.6-4.9eV) and exceptional Baliga's figure-of-merit (3444), β-Ga2O3 has emerged as a promising candidate for next-generation high-power electronic devices. However, this material faces a critical challenge in thermal management due to its relatively low thermal conductivity (27 W/m · K) compared to conventional semiconductors like Si (150 W/m·K), 4H-SiC (490 W/m·K), and GaN (230 W/m·K). To address this limitation, aluminum nitride (AlN) presents an ideal heteroepitaxial substrate solution, offering dual advantages: First, the (-201) β-Ga2O3 and (0001) AlN planes exhibit remarkably low lattice mismatch (2.4%), facilitating high-quality epitaxial growth. Second, AlN's superior thermal conductivity (340 W/m·K) effectively compensates for β-Ga2O3's thermal limitations. In this study, we employed low-pressure chemical vapor deposition (LPCVD) for β-Ga2O3 film growth on AlN substrates, motivated by its high deposition rate and cost-effectiveness. While process parameters crucially influence film quality, the argon-to-oxygen ratio - a critical yet underexplored growth parameter - remains insufficiently studied. We systematically investigated the effects of varying argon-oxygen ratios on the structural characteristics and surface morphology of β-Ga2O3 films. Through comprehensive XRD, AFM, SEM and XPS characterization, our work determines optimal process conditions that balance crystalline quality with surface uniformity.

Abstract

β-Ga2O3 thin films were heteroepitaxially grown on AlN(0001) substrates via low-pressure chemical vapor deposition (LPCVD). A comprehensive investigation was conducted to characterize the crystalline structure, surface morphology, and chemical composition of both the deposited films and heterostructures. X-ray diffraction (XRD) analysis revealed that the β-Ga2O3 films exhibited phase purity with a highly preferred (-201) growth orientation. The surface topography evolution under various growth conditions was systematically examined using scanning electron microscopy (SEM) and atomic force microscopy (AFM). X-ray photoelectron spectroscopy (XPS) measurements demonstrated an optimal Ga/O atomic ratio of 1.5, confirming the formation of stoichiometric Ga-O bonding configurations. These findings substantiate the feasibility of fabricating high-quality β-Ga2O3 films with superior physical properties through LPCVD heteroepitaxy on AlN substrates, thereby establishing a crucial foundation for developing next-generation Ga2O3-based power electronic devices.

Conclusion

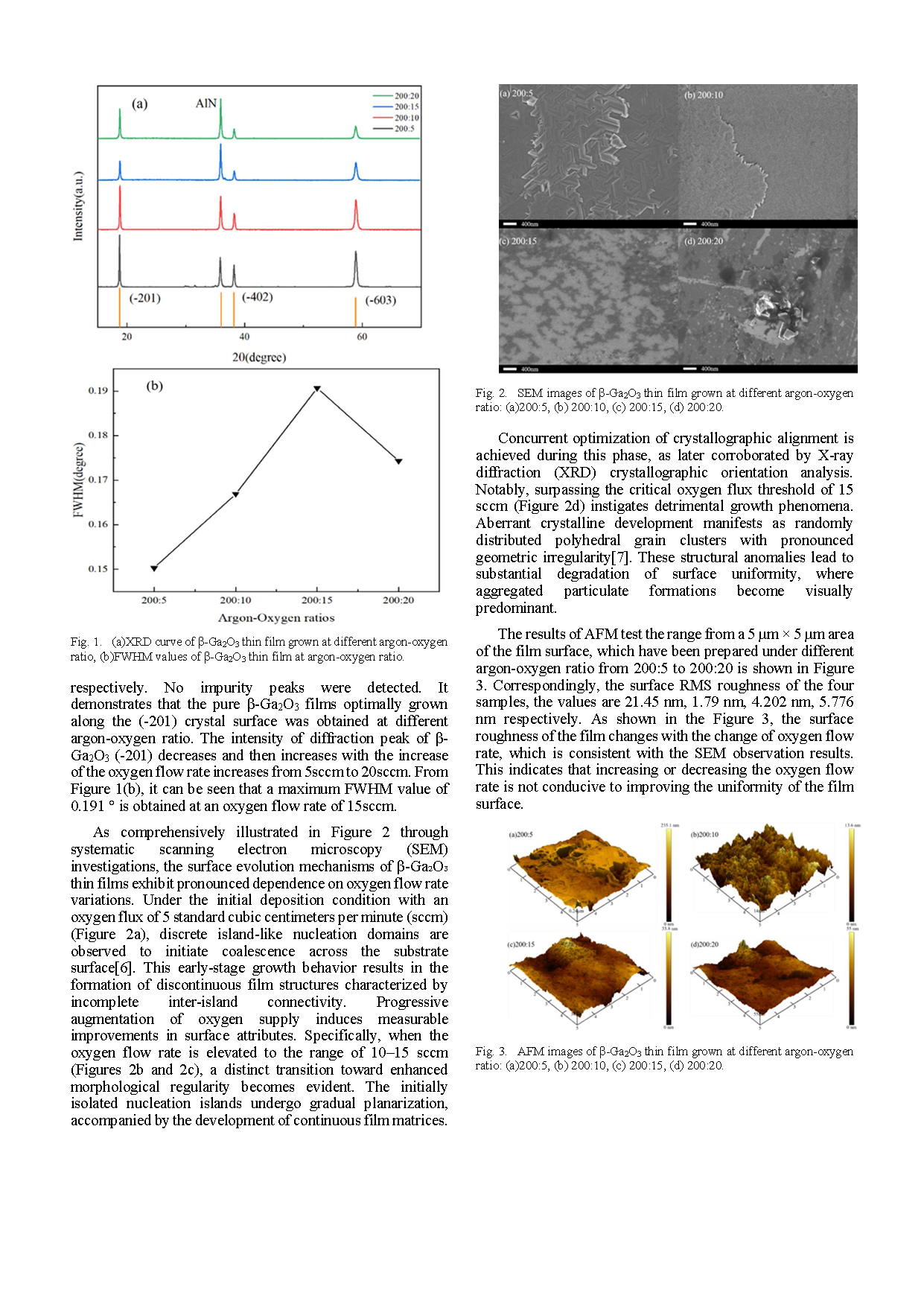

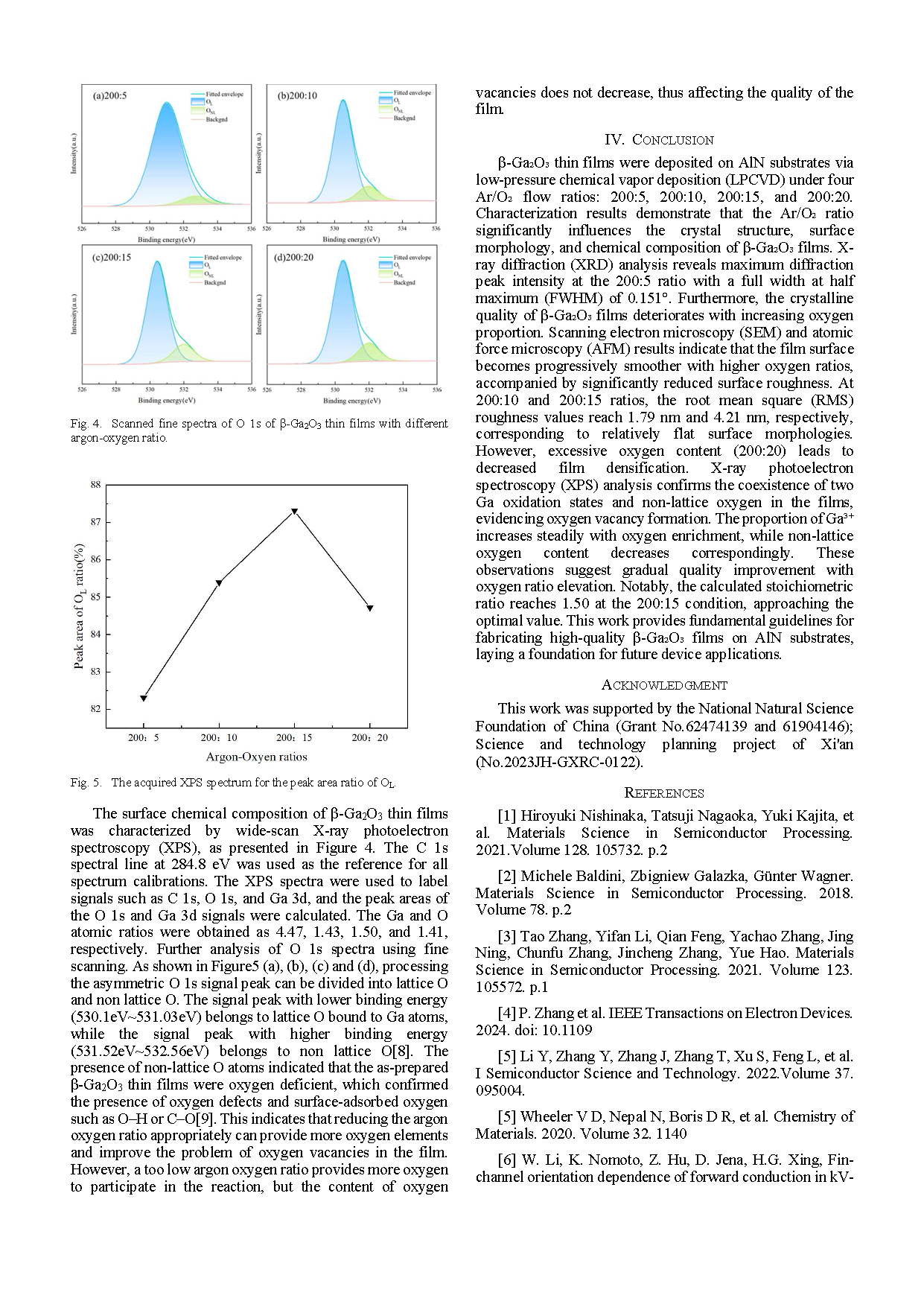

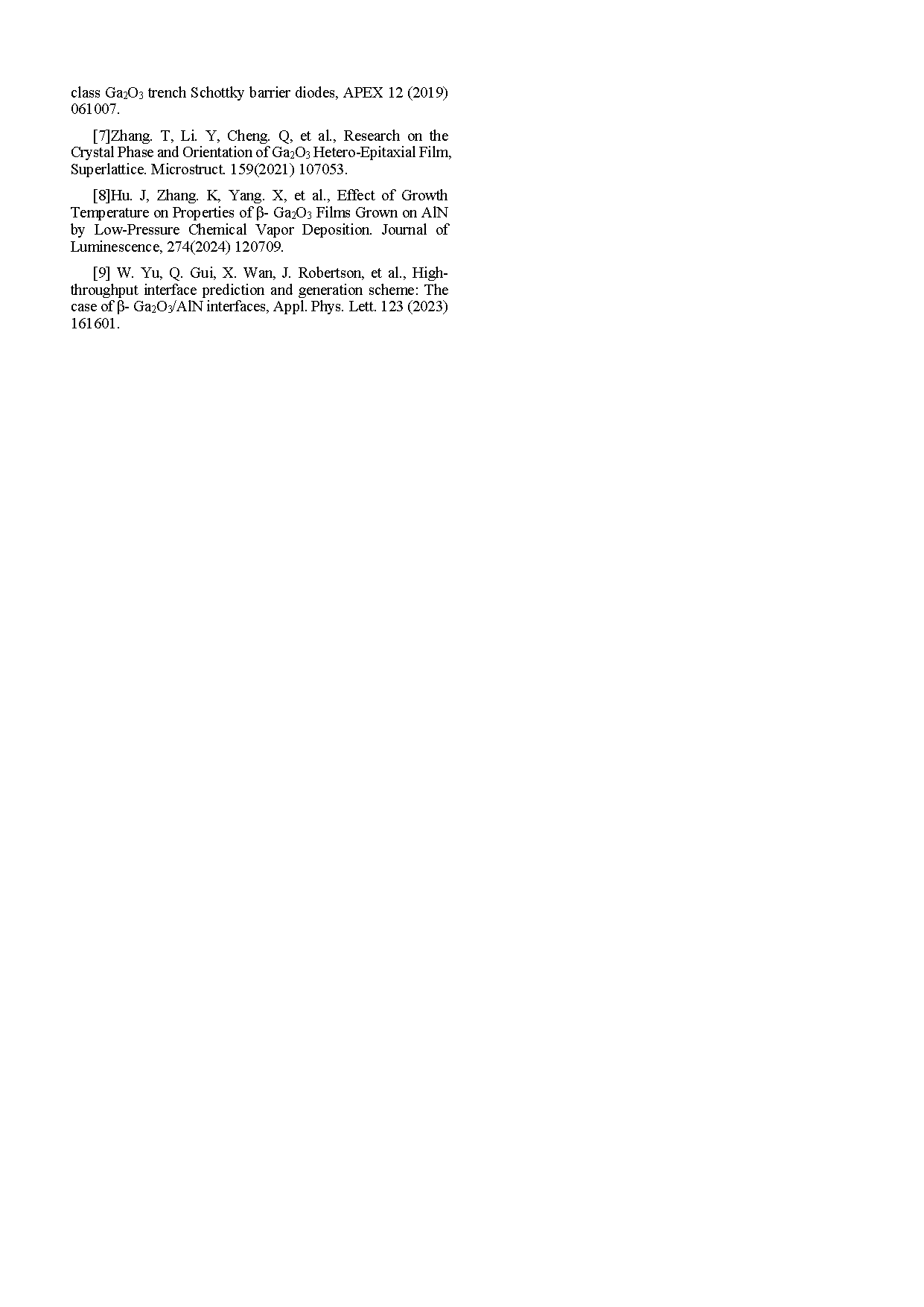

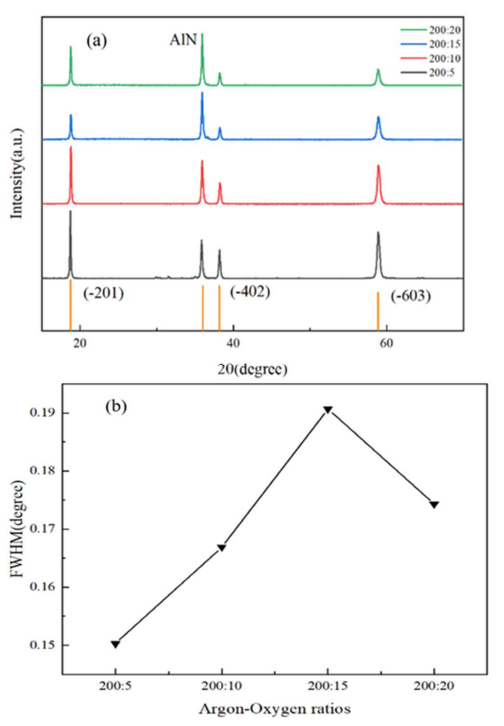

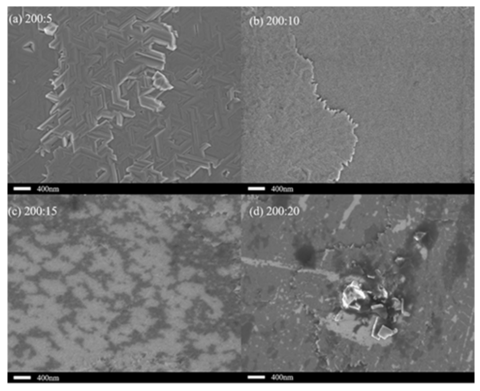

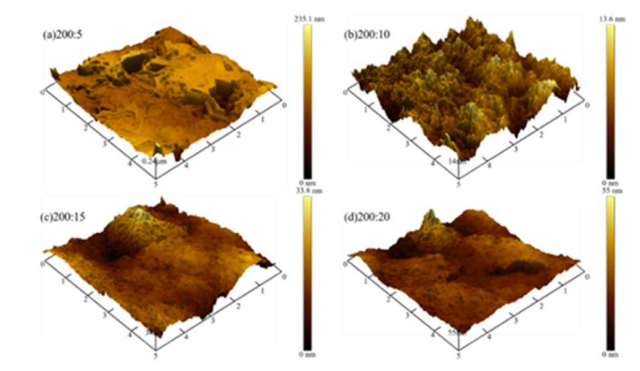

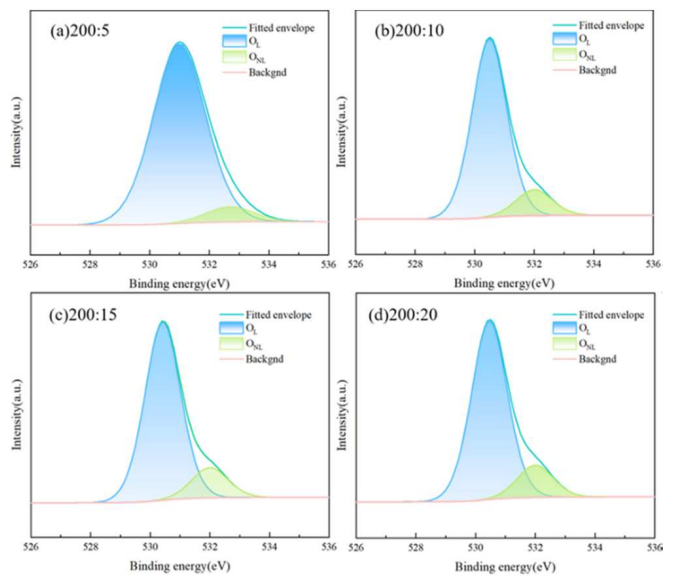

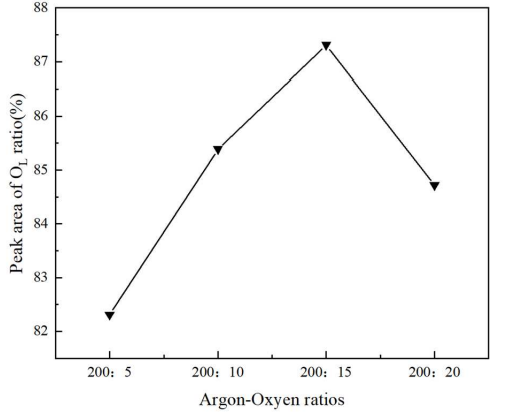

β-Ga2O3 thin films were deposited on AlN substrates via low-pressure chemical vapor deposition (LPCVD) under four Ar/O₂ flow ratios: 200:5, 200:10, 200:15, and 200:20. Characterization results demonstrate that the Ar/O₂ ratio significantly influences the crystal structure, surface morphology, and chemical composition of β-Ga2O3 films. X-ray diffraction (XRD) analysis reveals maximum diffraction peak intensity at the 200:5 ratio with a full width at half maximum (FWHM) of 0.151°. Furthermore, the crystalline quality of β-Ga2O3 films deteriorates with increasing oxygen proportion. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) results indicate that the film surface becomes progressively smoother with higher oxygen ratios, accompanied by significantly reduced surface roughness. At 200:10 and 200:15 ratios, the root mean square (RMS) roughness values reach 1.79 nm and 4.21 nm, respectively, corresponding to relatively flat surface morphologies. However, excessive oxygen content (200:20) leads to decreased film densification. X-ray photoelectron spectroscopy (XPS) analysis confirms the coexistence of two Ga oxidation states and non-lattice oxygen in the films, evidencing oxygen vacancy formation. The proportion of Ga3+ increases steadily with oxygen enrichment, while non-lattice oxygen content decreases correspondingly. These observations suggest gradual quality improvement with oxygen ratio elevation. Notably, the calculated stoichiometric ratio reaches 1.50 at the 200:15 condition, approaching the optimal value. This work provides fundamental guidelines for fabricating high-quality β-Ga2O3 films on AlN substrates, laying a foundation for future device applications.

Fig. 1. (a)XRD curve of β-Ga2O3 thin film grown at different argon-oxygen ratio, (b)FWHM values of β-Ga2O3 thin film at argon-oxygen ratio.

Fig. 2. SEM images of β-Ga2O3 thin film grown at different argon-oxygen ratio: (a)200:5, (b) 200:10, (c) 200:15, (d) 200:20.

Fig. 3. AFM images of β-Ga2O3 thin film grown at different argon-oxygen ratio: (a)200:5, (b) 200:10, (c) 200:15, (d) 200:20.

Fig. 4. Scanned fine spectra of O 1s of β-Ga2O3 thin films with different argon-oxygen ratio.

Fig. 5. The acquired XPS spectrum for the peak area ratio of OL.

DOI:

doi.org/10.1109/WiPDA-Asia63772.2025.11183966