【International Papers】β-Ga₂O₃ crystal growth with cold container crucibles: Large-scale oxide crystal growth from cold crucible method

日期:2025-12-18阅读:337

Researchers from the FOX Corporation have published a dissertation titled "β-Ga2O3 crystal growth with cold container crucibles: Large-scale oxide crystal growth from cold crucible method" in Journal of Crystal Growth.

Background

Wide-bandgap (WBG) semiconductors—such as silicon carbide (SiC), gallium nitride (GaN), diamond, and gallium oxide (Ga2O3)—are promising candidates for next-generation power devices owing to their ability to operate under high-voltage, high-frequency, and high-temperature conditions. These properties enable considerable reductions in energy loss during power conversion, which is essential for energy-efficient electronics. Among of them, β-Ga2O3 has garnered attention as a melt-grown WBG semiconductor like silicon by using bulk single-crystal melt-growth methods, such as the Czochlralski (Cz), Bridgeman–Stockbargar, and edge-defined film-fed growth (EFG) methods. β-Ga2O3 bulk growth has demonstrated growth rates of up to 15 mm/h by EFG—much faster than those of SiC or GaN. This scalability makes it an economically attractive candidate for power electronics.

Abstract

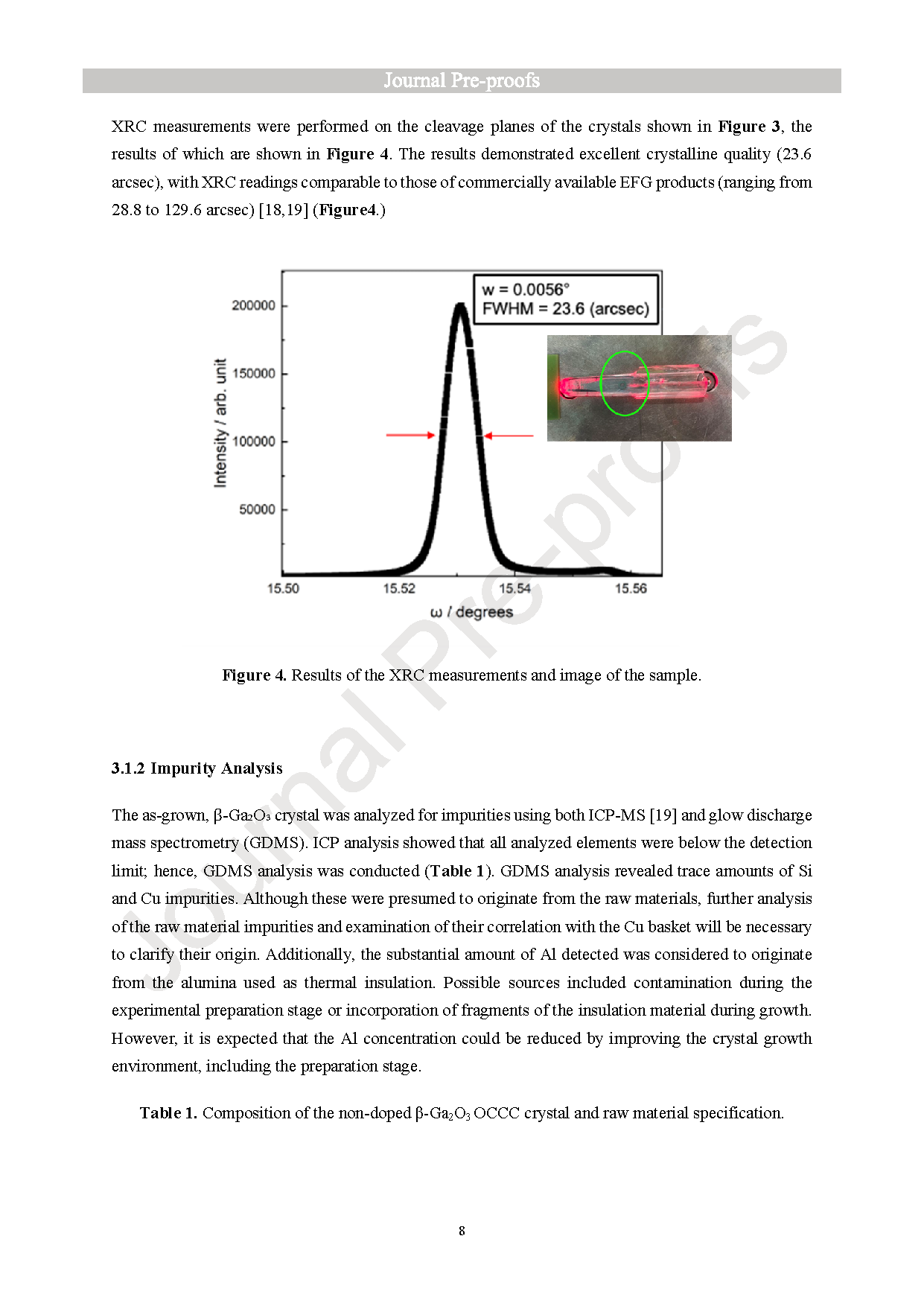

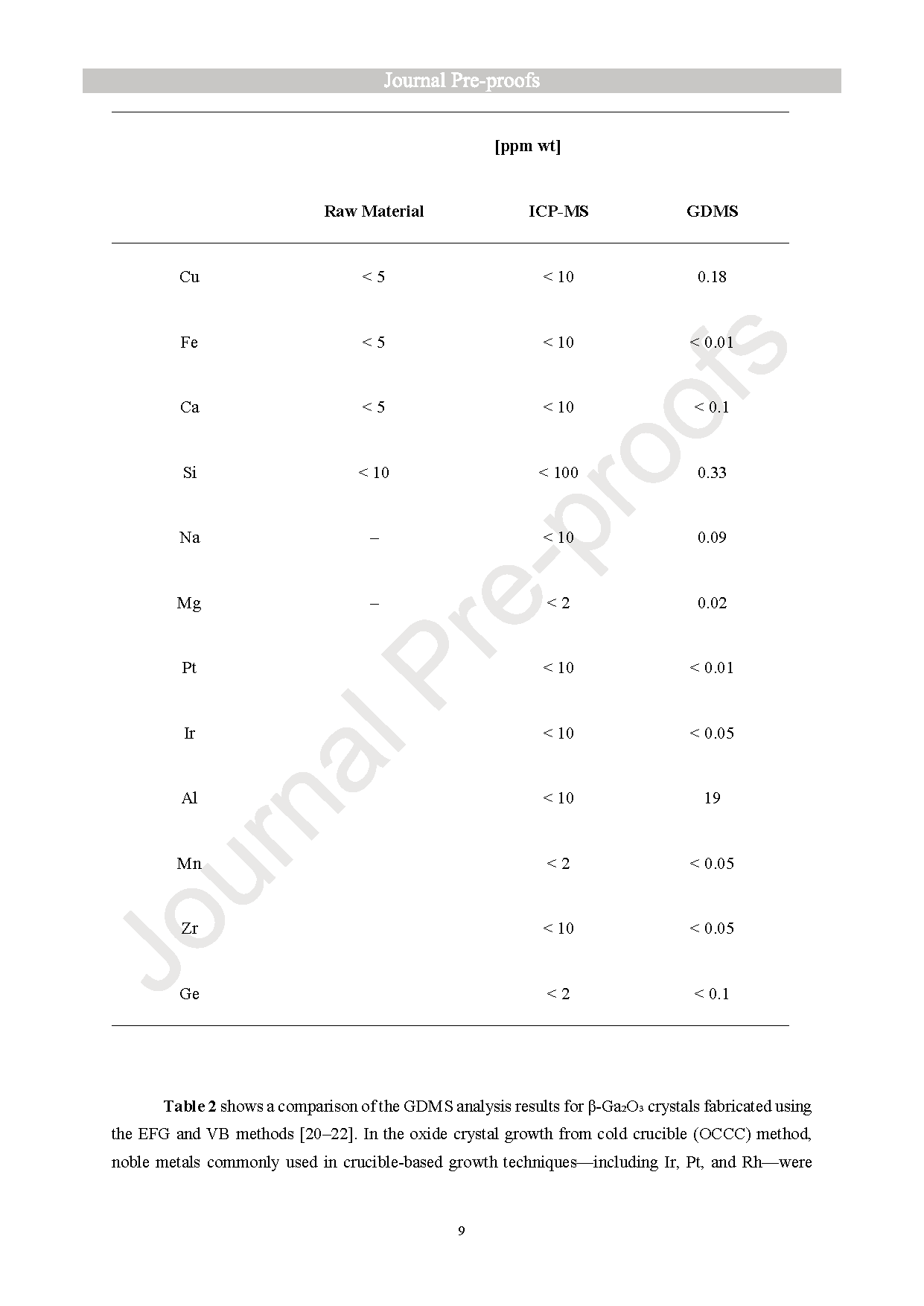

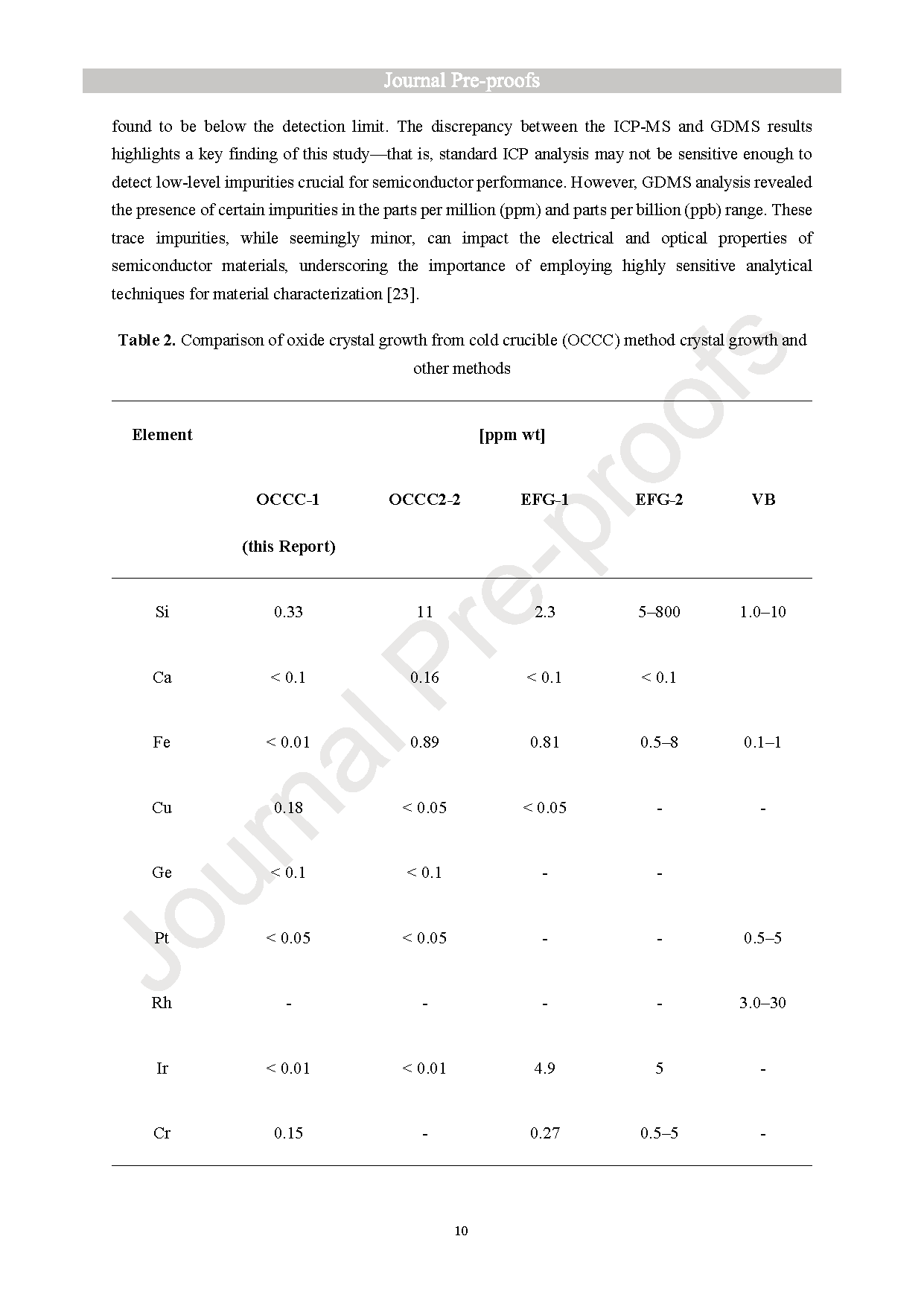

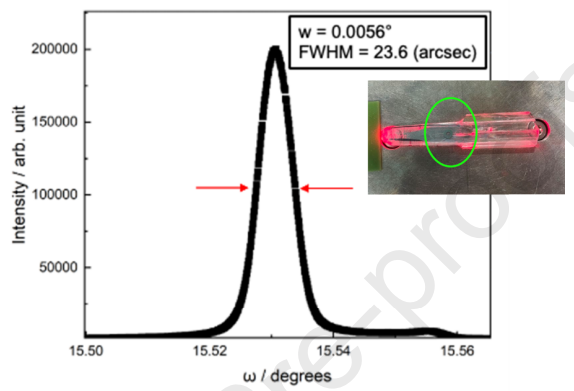

Oxide crystal growth from cold crucible was applied to trial enlargement of β-Ga2O3 single crystals in both diameter and length. Using a 150-mm Cu basket with automatic diameter control, stable seeding, necking, and shoulder formation were achieved. Consequently, single crystals with diameters of up to 32 mm and body lengths of 50.8 mm (2 in.) were successfully obtained, demonstrating considerable progress in crystal scaling. X-ray rocking curve analysis confirmed the full width at half maximum values, which were comparable to those of edge-defined film-fed growth substrates. Glow discharge mass spectrometry revealed no trace of Ir, Pt, and Rh impurities. These findings highlight the oxide crystal growth from cold crucibleas a scalable, contamination-free, and cost-effective method for producing large β-Ga2O3 crystals, advancing their potential for power electronic applications.

Highlights

● Oxide crystal growth from cold crucible enabled β-Ga2O3 crystal growth without expensive noble-metal crucibles.

● Successful trial enlargement: 32-mm diameter and 50.8-mm (2-in.) body length achieved.

● Stable diameter control during seeding, necking, and shoulder formation was demonstrated.

● High crystalline quality confirmed by XRC, comparable to commercial EFG substrates.

Conclusions

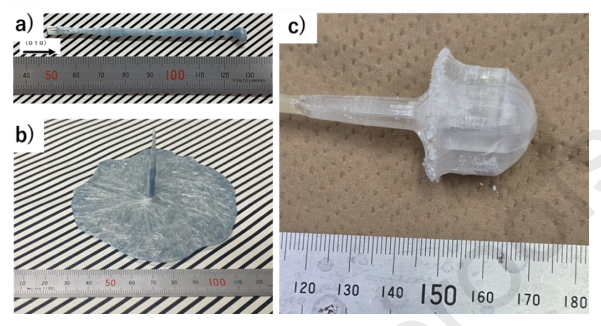

In this study, large β-Ga2O3 single crystals were successfully grown using the crucible-free oxide crystal growth from cold crucible method which are called OCCC method. By employing a newly designed 150-mm-diameter Cu basket and high-frequency SiC-based power generator, stable ADC during the necking, shoulder, and body formation processes could be achieved. Consequently, single crystals with diameters up to 38.1 mm (1.5 in.) and body lengths of 50.8 mm (2 in.) could be obtained. The XRC measurements demonstrated excellent crystalline quality comparable to that of EFG-grown crystals, while impurity analysis confirmed the absence of contamination from noble-metal crucibles, with only trace levels of raw-material-derived impurities detected. These findings highlight the feasibility of the OCCC method as a scalable and cost-effective alternative to conventional crucible-based techniques for β-Ga2O3 growth. The elimination of Ir, Pt, and Rh contamination and the capability to operate under arbitrary oxygen partial pressures provide considerable advantages for both the crystal quality and process sustainability. Future work should focus on further optimization of the thermal field control, enlargement of crystal size, and reduction of residual impurities, paving the way toward practical applications of OCCC-grown β-Ga2O3 substrates in next-generation power electronic devices.

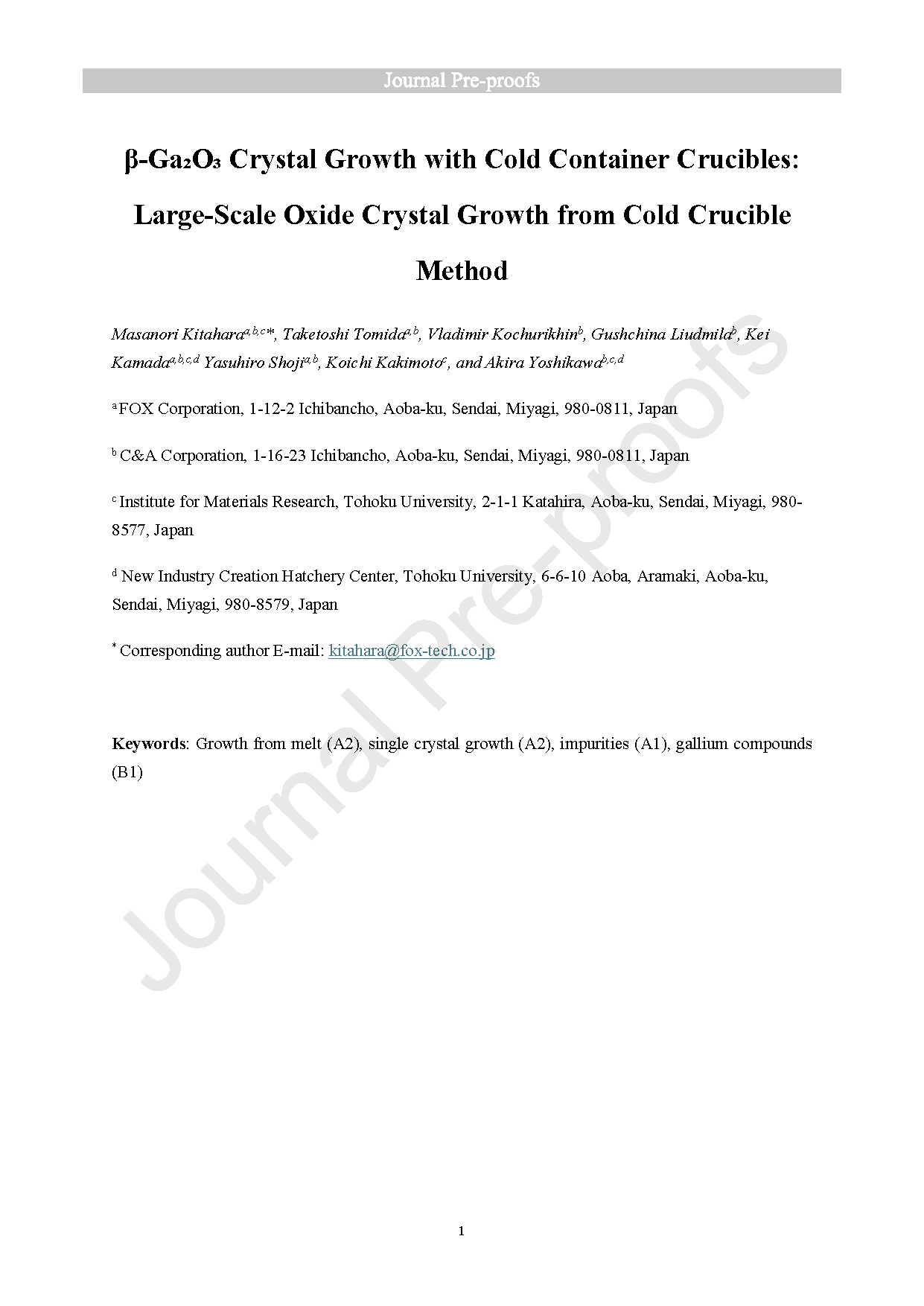

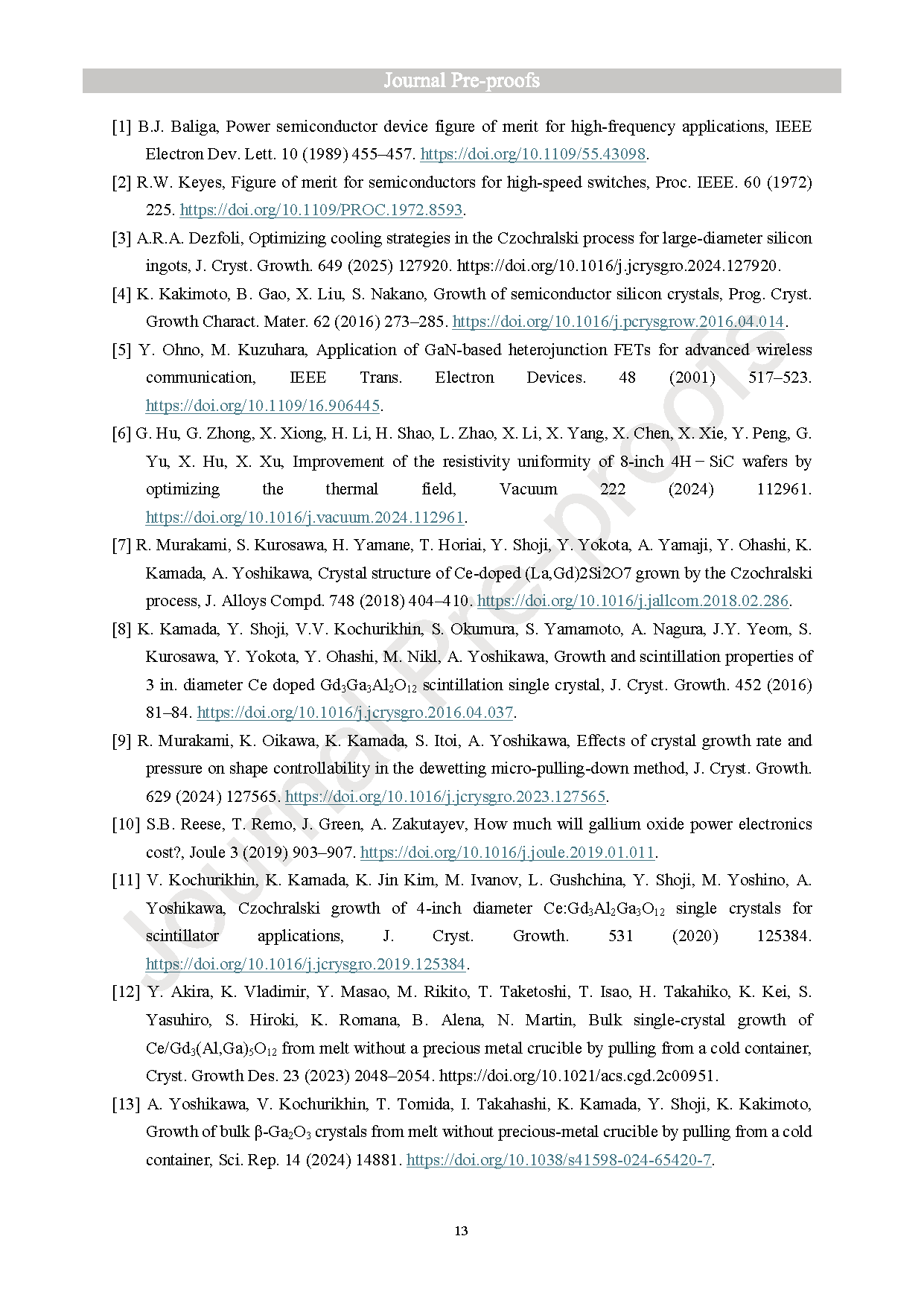

Figure 1. Schematic of the oxide crystal growth from cold crucible (OCCC) method.

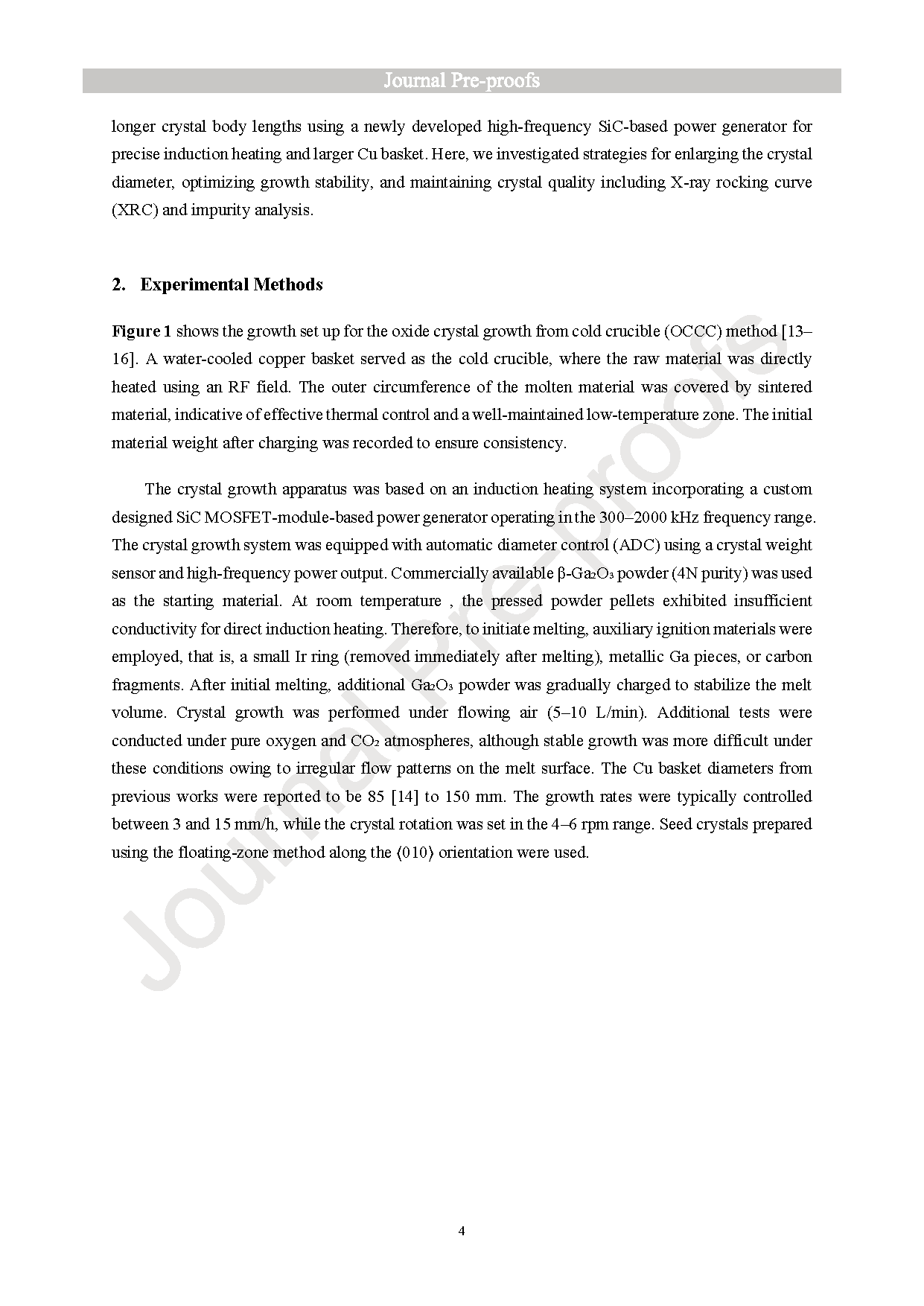

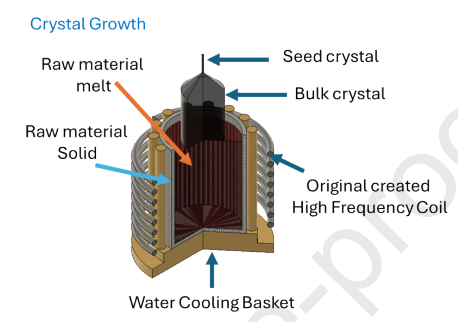

Figure 2. (a) β-Ga2O3 crystal grown after an extended necking process, (b) crystal obtained from the diameter-enlargement trial, and (c) crystal with a diameter of approximately 20 mm and body length of 10 mm.

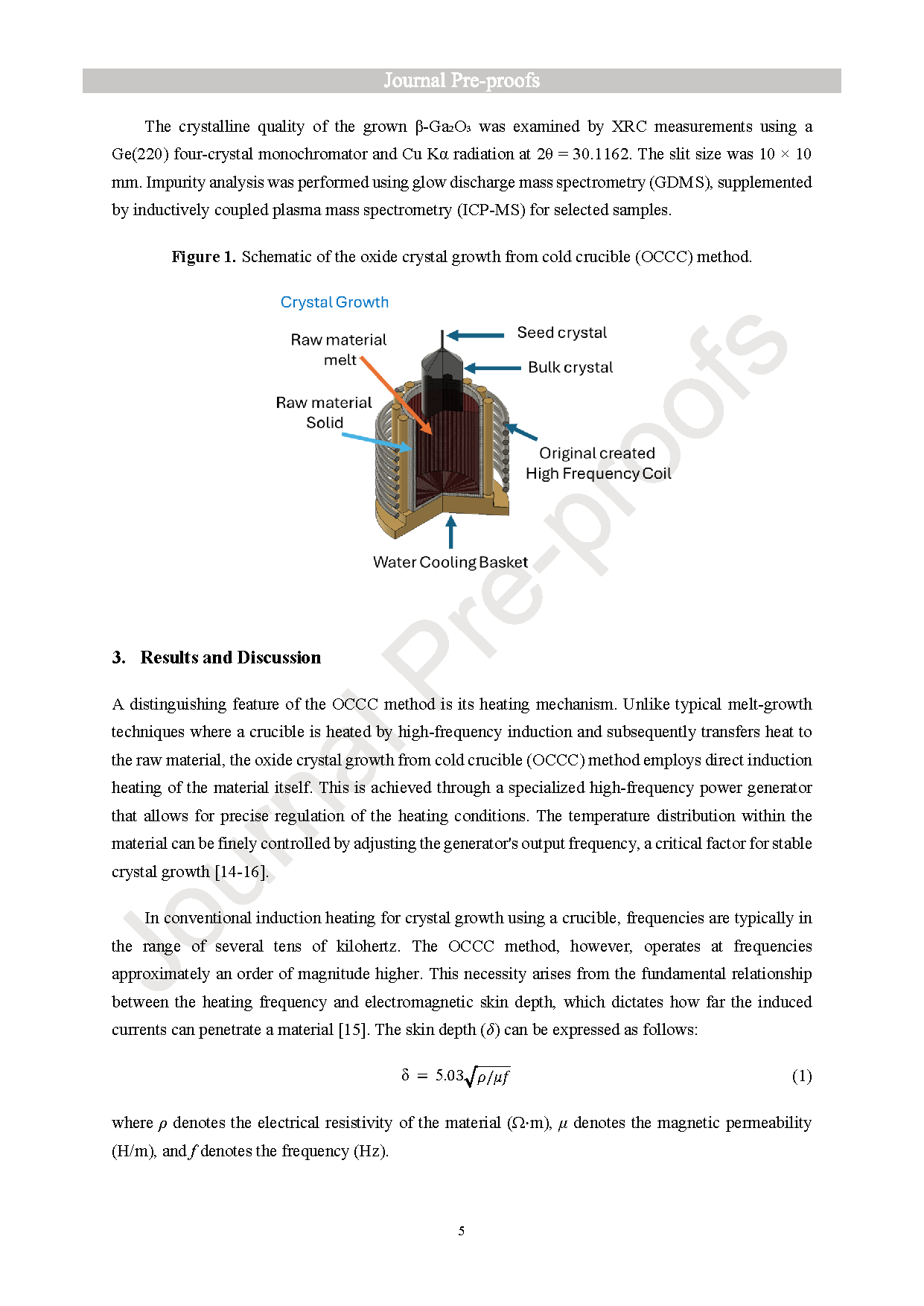

Figure 3. (a) β-Ga2O3 crystal grown with 32-mm diameter and 50.8-mm (2-in.) length, (b), (c) crystal with 40-mm diameter and 15-mm length.

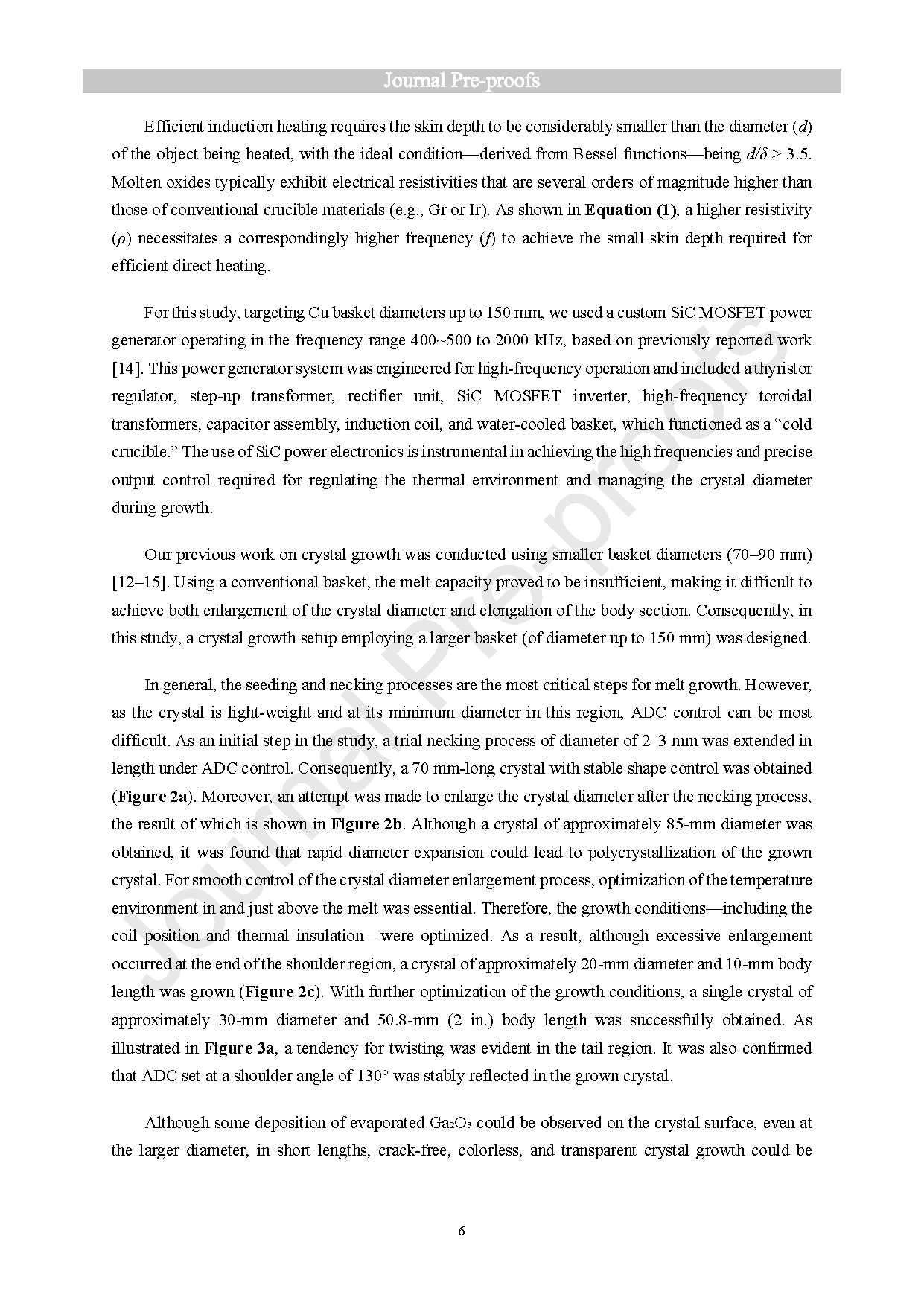

Figure 4. Results of the XRC measurements and image of the sample.

DOI:

doi.org/10.1016/j.jcrysgro.2025.128461