【Member Papers】Explainable Analysis and Optimization of the Thermal Field in Gallium Oxide Single Crystal Growth Based on Machine Learning

日期:2026-01-26阅读:44

Researchers from the Wuhan University have published a dissertation titled " Explainable Analysis and Optimization of the Thermal Field in Gallium Oxide Single Crystal Growth Based on Machine Learning " in Crystal Growth & Design.

Background

Single-crystal β-Ga₂O₃ exhibits exceptional properties such as an ultra-wide bandgap and high breakdown field, showing great potential for next-generation power electronics and deep-ultraviolet optoelectronic devices. The edge-defined film-fed growth (EFG) method is a key technique for producing high-quality β-Ga₂O₃ single crystals, where precise control of the thermal field distribution is critical for determining crystal quality. However, conventional thermal field optimization heavily relies on experimental trial-and-error and localized numerical simulations, making it difficult to globally and deeply reveal the intrinsic physical mechanisms during the growth process. Machine learning techniques, as data-driven analytical tools, have the potential to uncover latent patterns in the complex crystal growth process and provide new insights for thermal field design.

Abstract

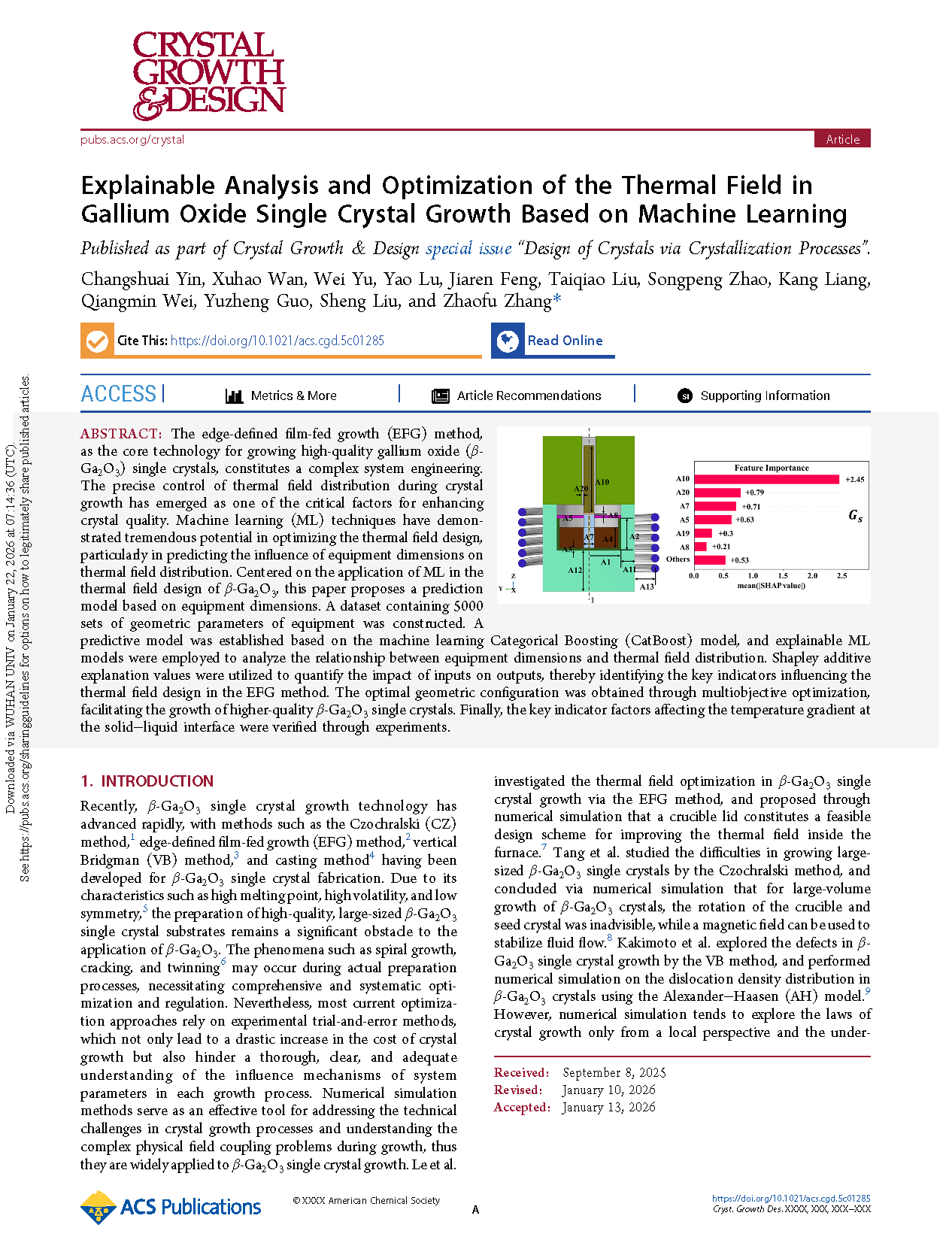

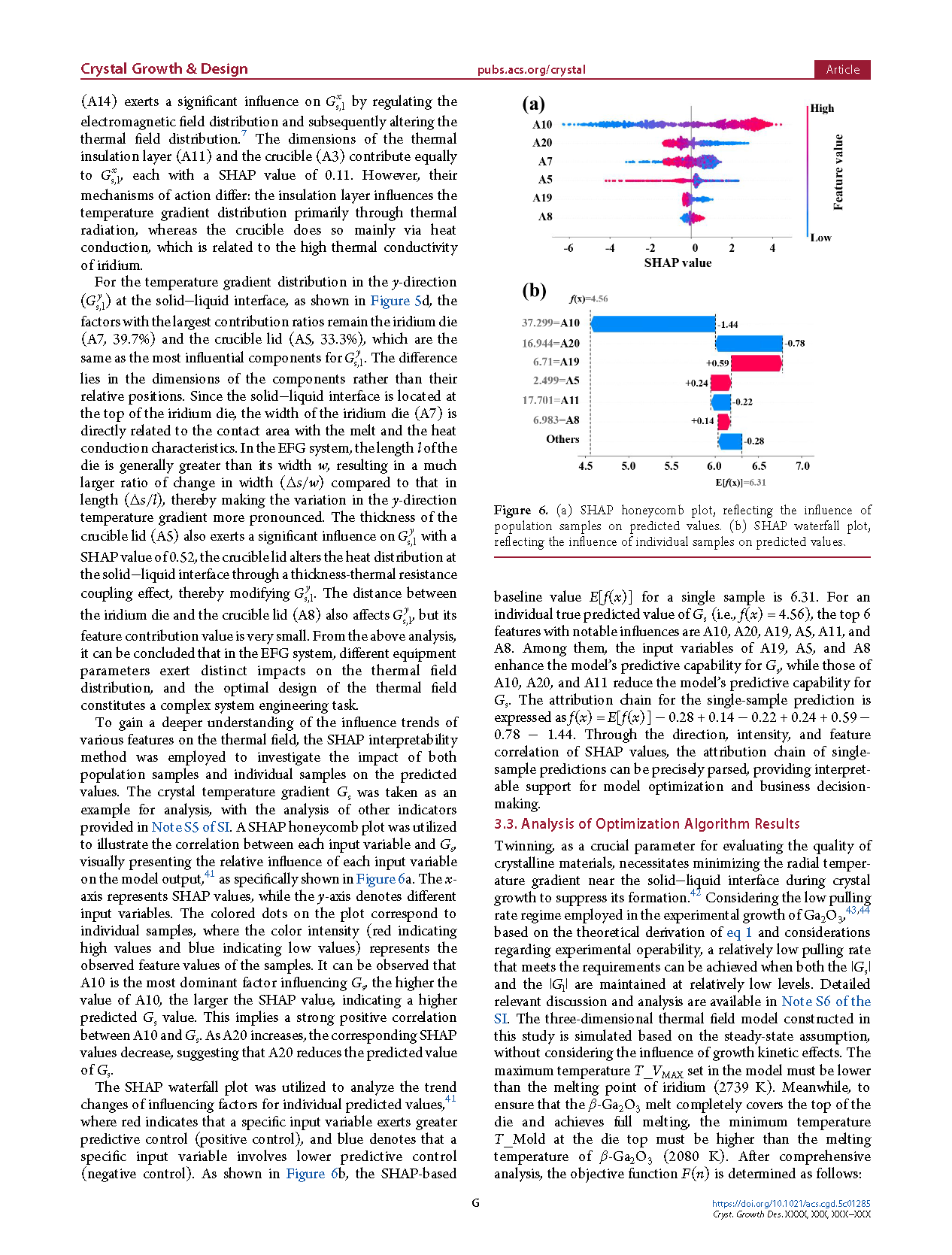

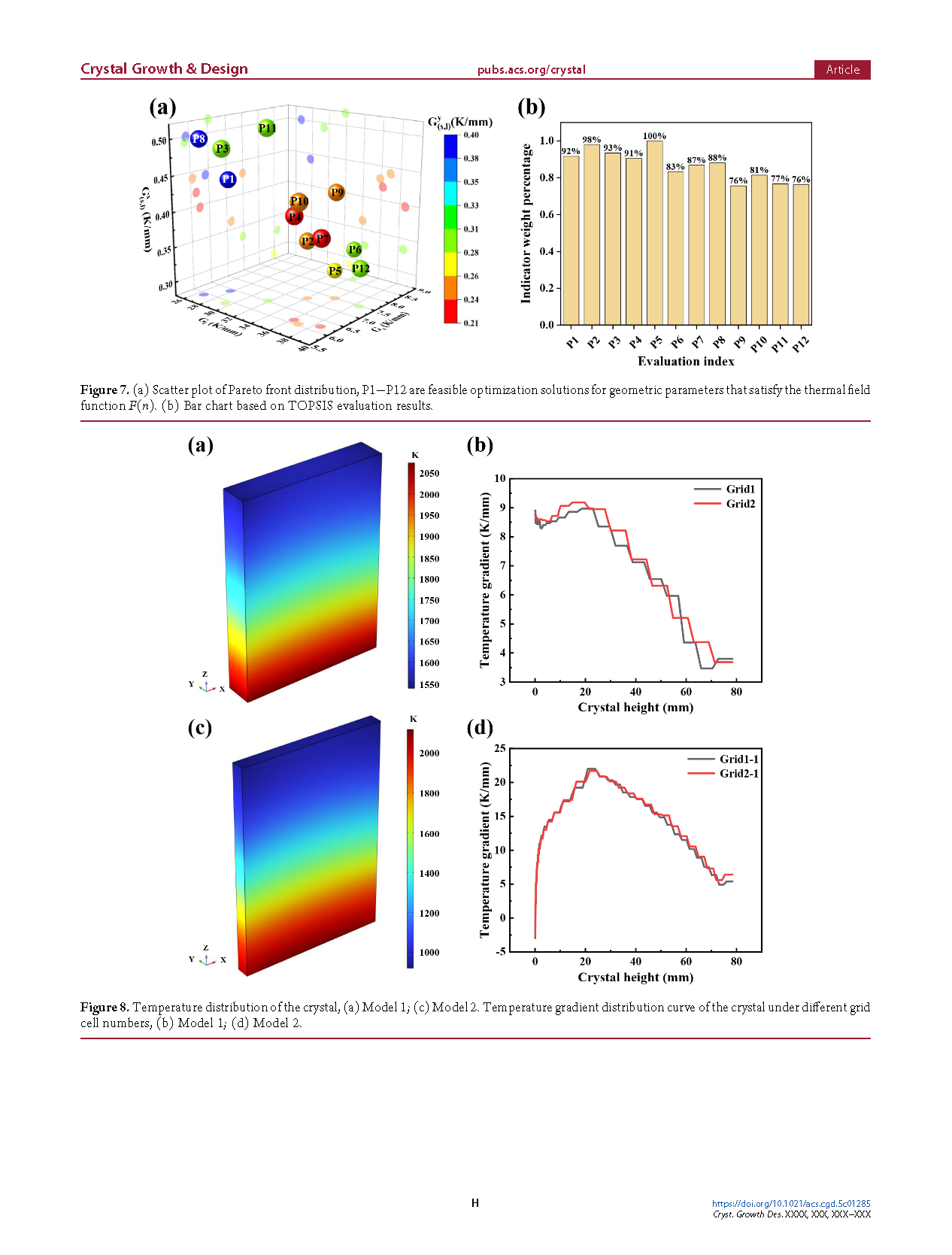

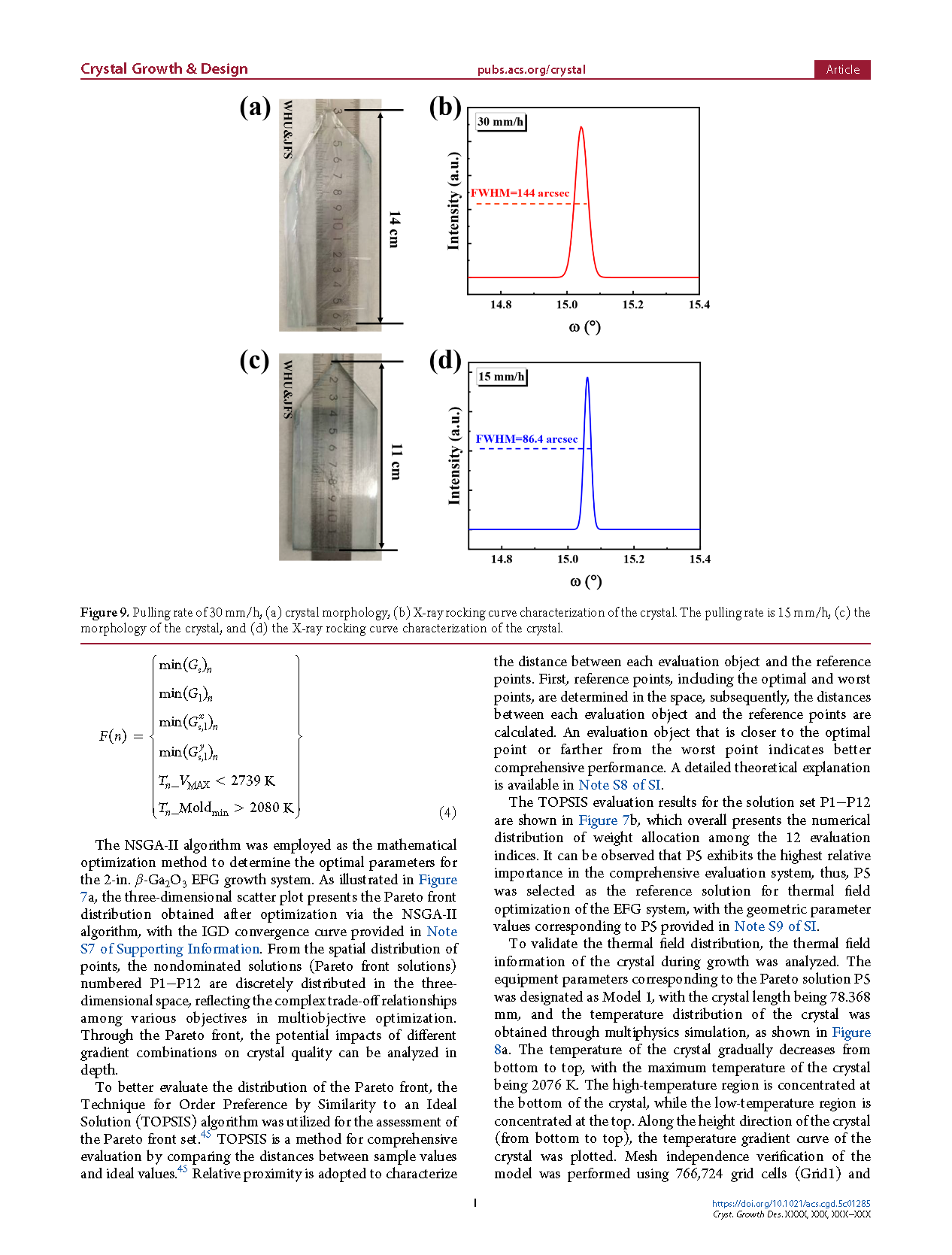

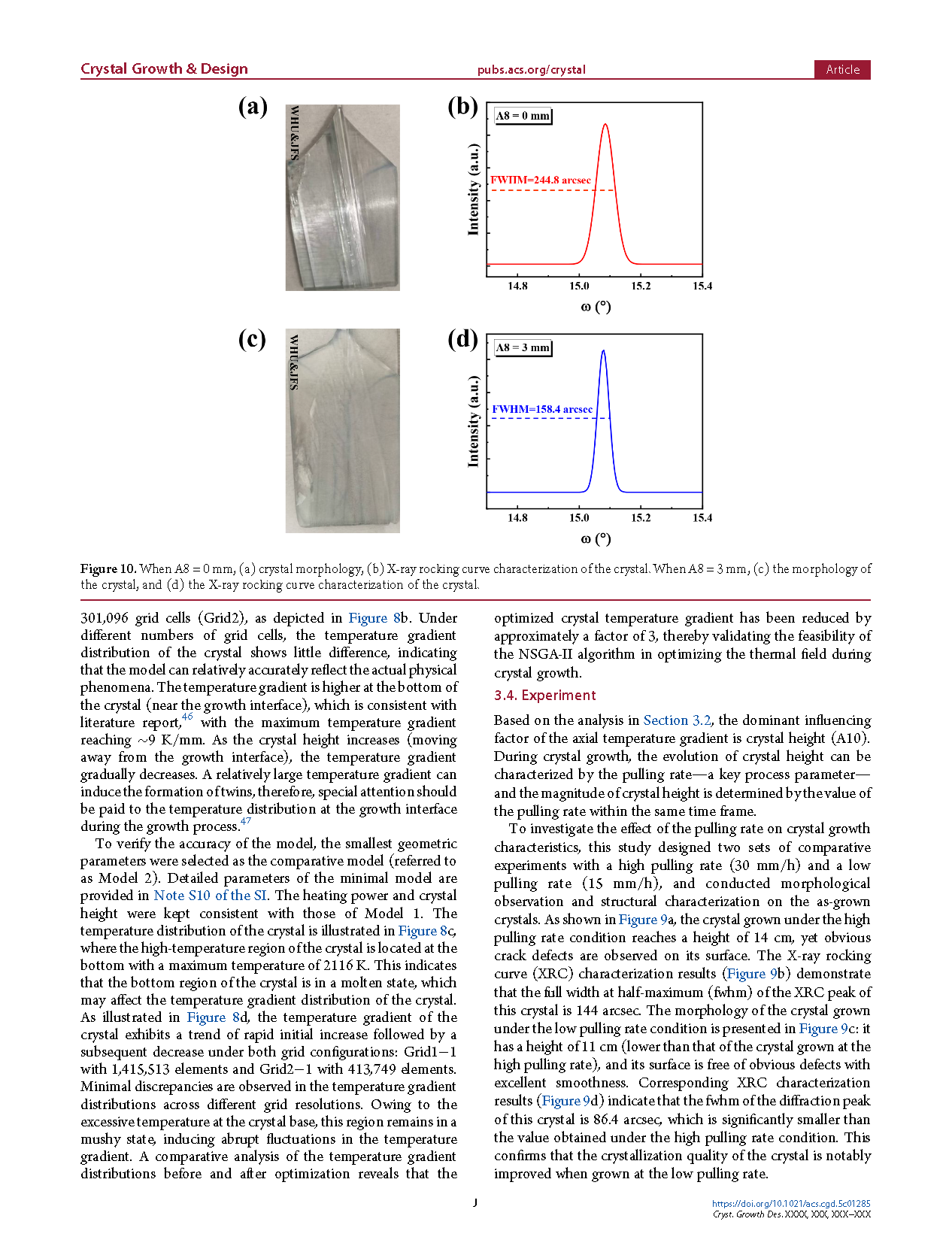

The edge-defined film-fed growth (EFG) method, as the core technology for growing high-quality gallium oxide (β-Ga2O3) single crystals, constitutes a complex system engineering. The precise control of thermal field distribution during crystal growth has emerged as one of the critical factors for enhancing crystal quality. Machine learning (ML) techniques have demonstrated tremendous potential in optimizing the thermal field design, particularly in predicting the influence of equipment dimensions on thermal field distribution. Centered on the application of ML in the thermal field design of β-Ga2O3), this paper proposes a prediction model based on equipment dimensions. A dataset containing 5000 sets of geometric parameters of equipment was constructed. A predictive model was established based on the machine learning Categorical Boosting (CatBoost) model, and explainable ML models were employed to analyze the relationship between equipment dimensions and thermal field distribution. Shapley additive explanation values were utilized to quantify the impact of inputs on outputs, thereby identifying the key indicators influencing the thermal field design in the EFG method. The optimal geometric configuration was obtained through multiobjective optimization,facilitating the growth of higher-quality β-Ga2O3) single crystals. Finally, the key indicator factors affecting the temperature gradient at the solid−liquid interface were verified through experiments.

Conclusion

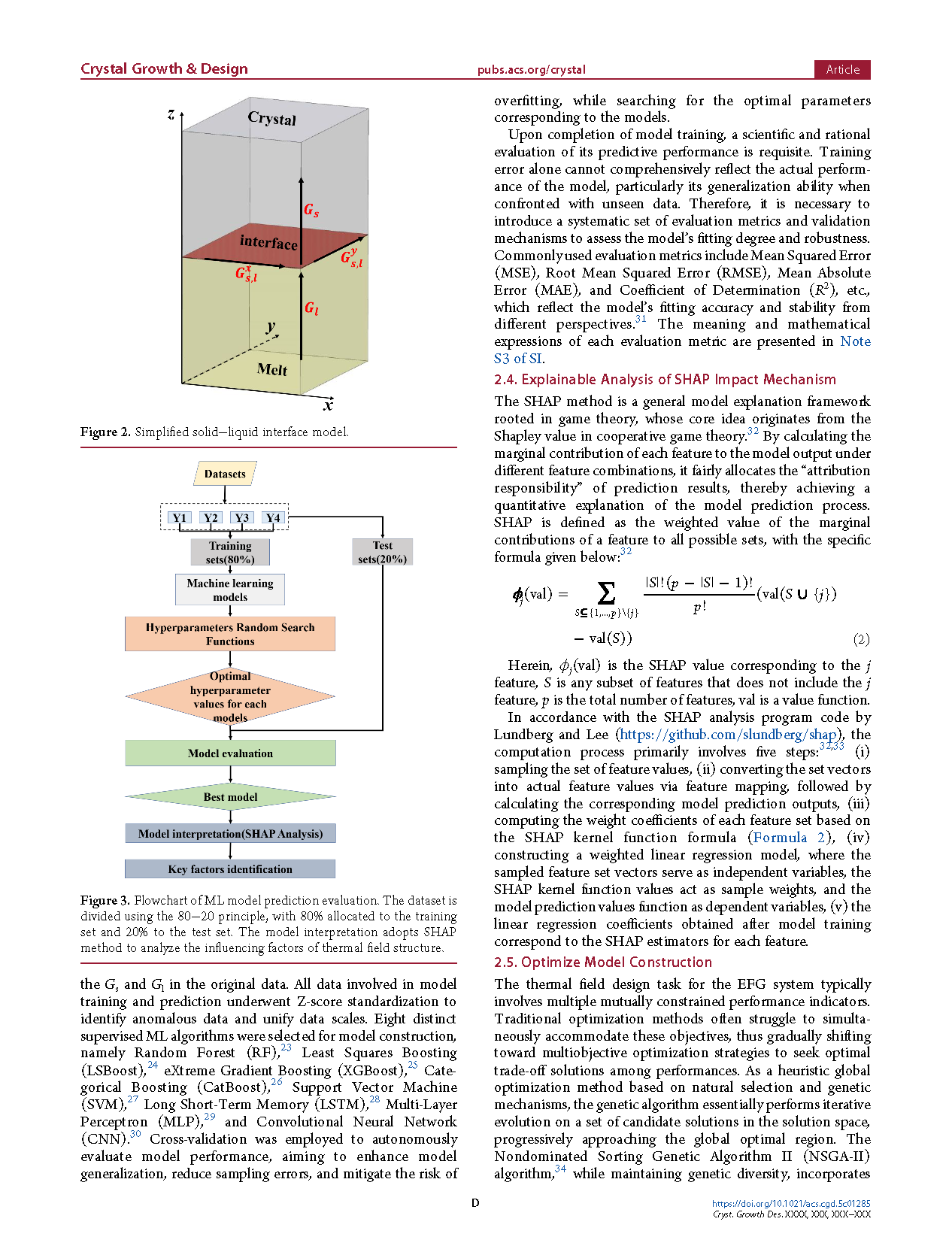

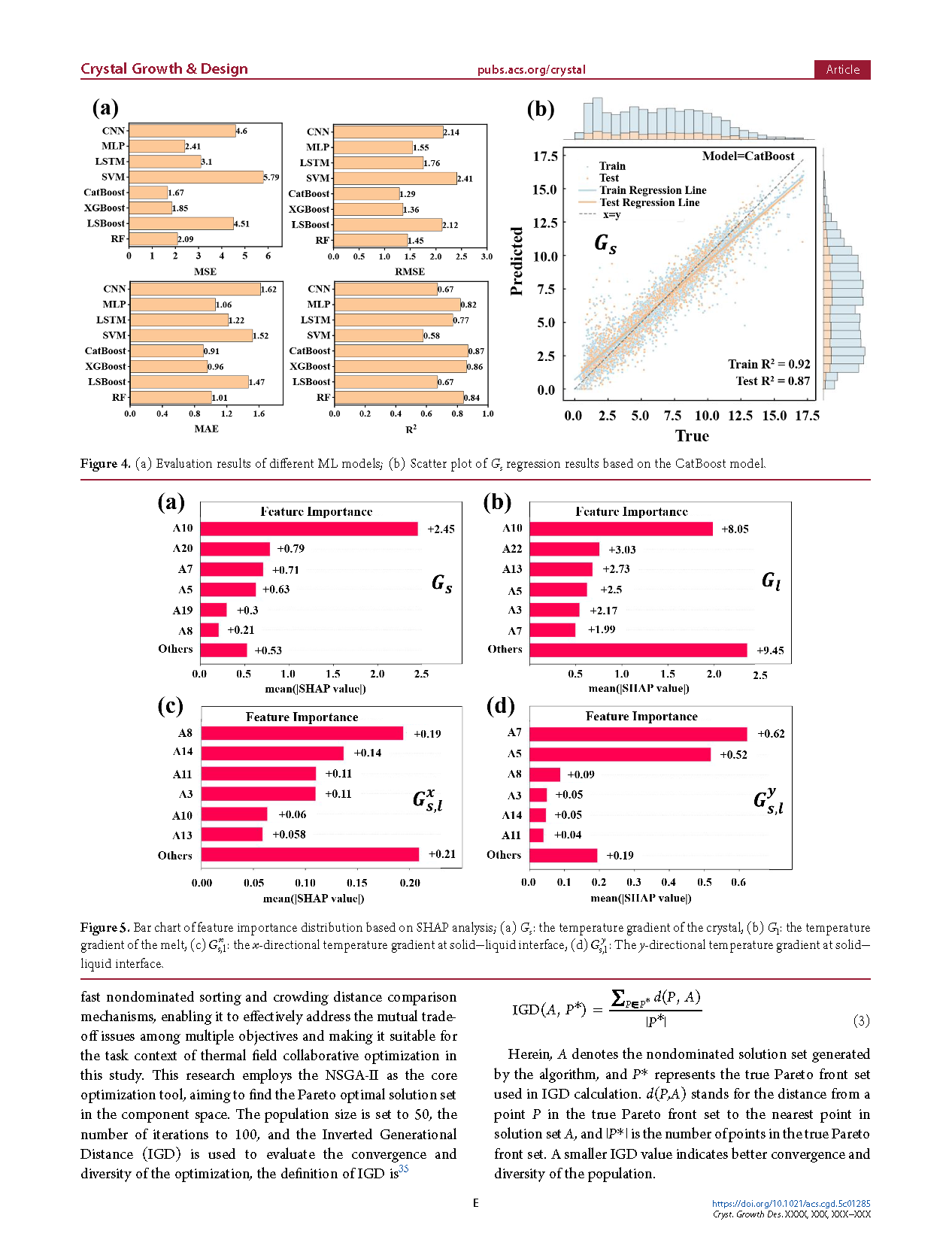

This study innovatively introduces machine learning techniques into the thermal field design of β-Ga₂O₃ single-crystal growth, establishing an intelligent thermal field optimization model based on equipment size prediction. Through high-accuracy CatBoost prediction, SHAP-based interpretability analysis, and NSGA-II multi-objective optimization, the key parameters governing thermal field regulation were identified and the optimal device geometric configuration was obtained. This work provides a new technical pathway and theoretical guidance for the high-quality and controllable growth of β-Ga₂O₃ single crystals. Beyond this specific system, the study also advances the application of machine learning in materials fabrication and offers an analytical framework that can be extended to thermal field design in the growth of other functional crystals.

Figure 1. Overall framework diagram of the paper. (a) Typical components based on EFG system for equipment size data set acquisition. (b) Threedimensional thermal field data information on EFG system. (c) The integration of interpretable ML models and optimization techniques based on SHAP.

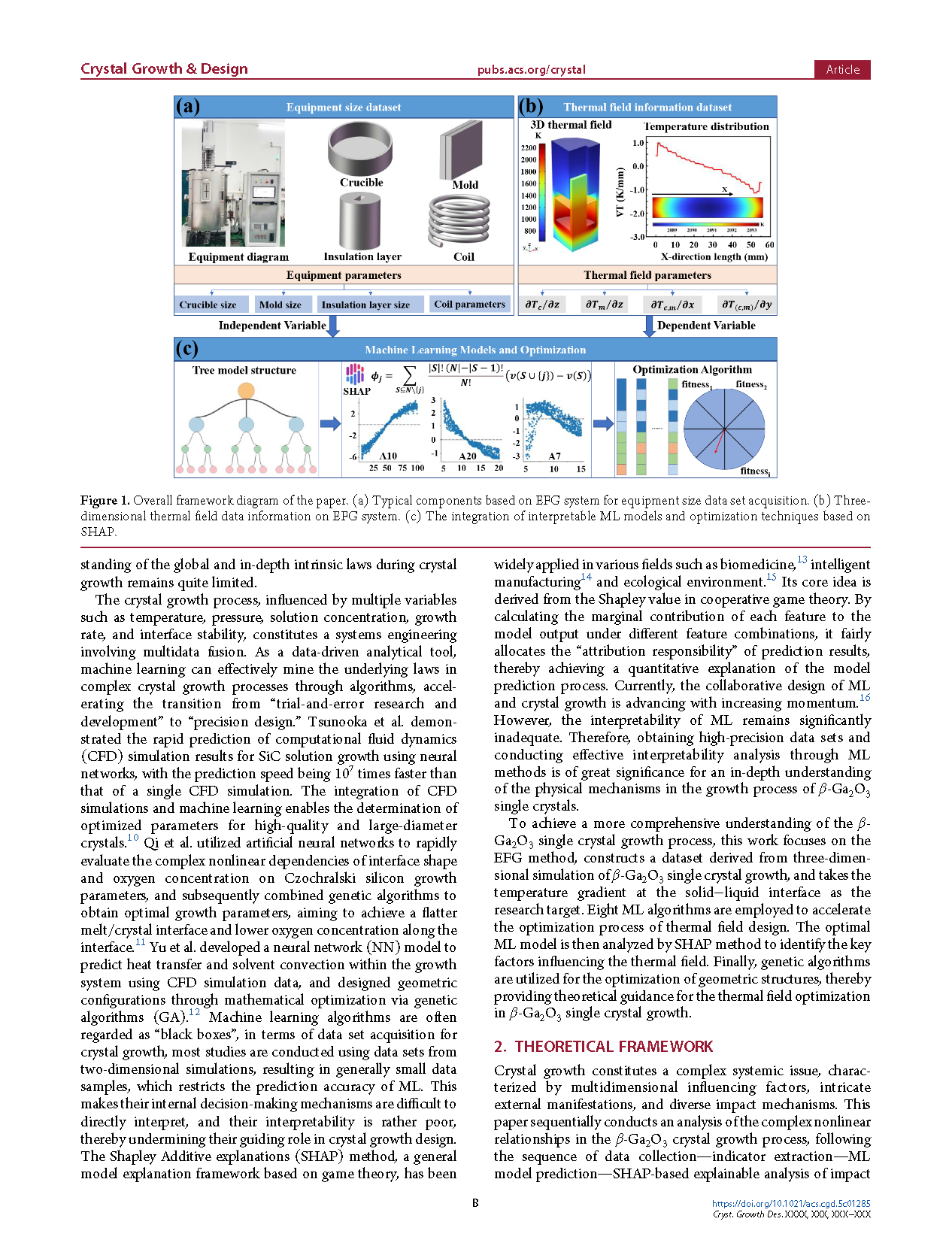

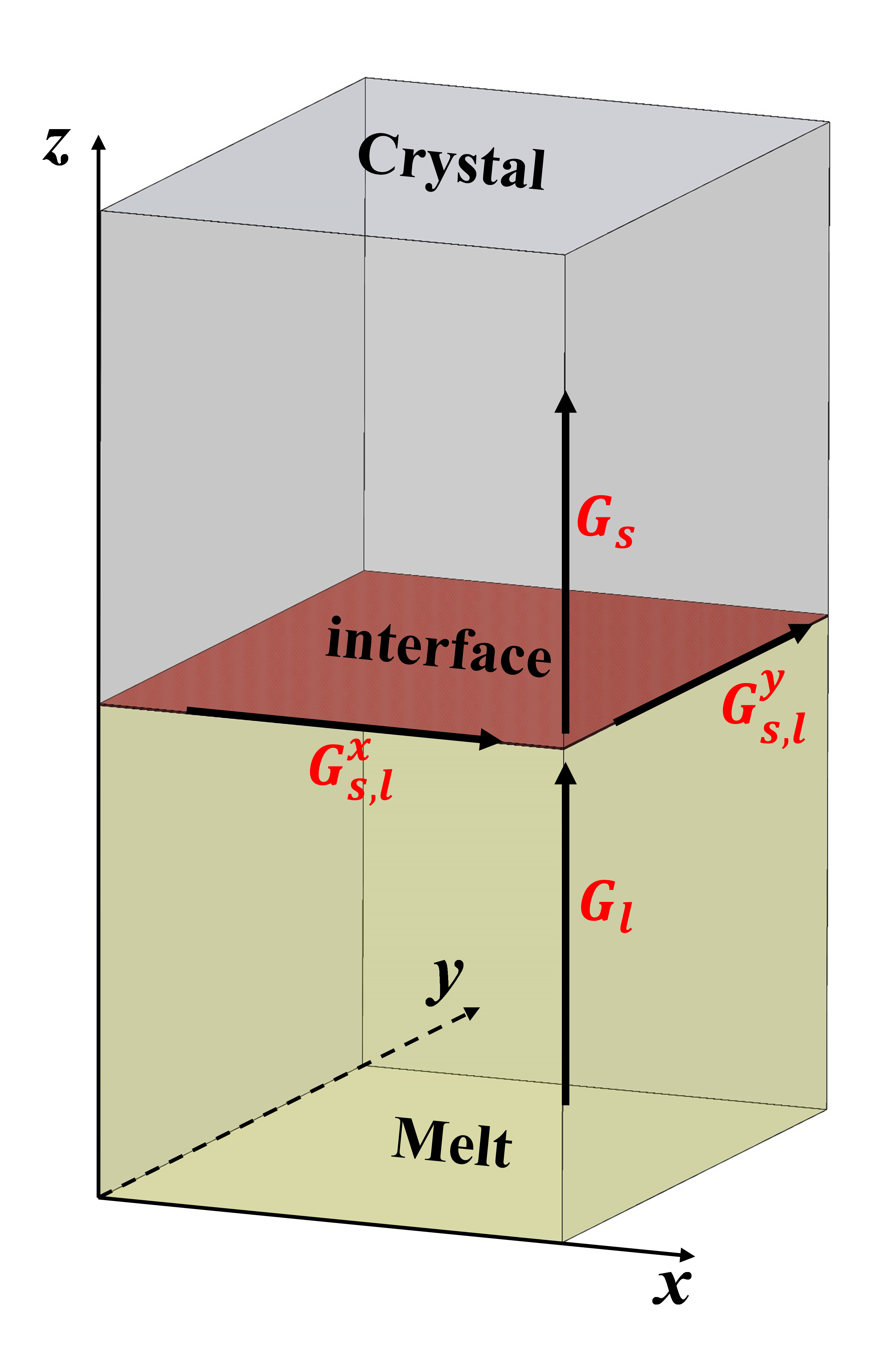

Figure 2. Simplified solid−liquid interface model.

Figure 5. Bar chart of feature importance distribution based on SHAP analysis; (a) Gs: the temperature gradient of the crystal, (b) Gl: the temperature gradient of the melt, (c) Gxs,l : the x-directional temperature gradient at solid−liquid interface, (d) Gys,l : The y-directional temperature gradient at solid−liquid interface.

DOI:

doi.org/10.1021/acs.cgd.5c01285