【World Express】The world's first Gallium Oxide single crystal growth method without the use of precious metal crucible, paving the way for the field of Gallium Oxide power semiconductors at an ultra-low cost

日期:2024-08-01阅读:1477

A team led by Keisuke Kamada, president of C&A, a startup founded at Tohoku University in Japan, and Professor Akira Yoshikawa of the Institute of Materials Research at Tohoku University developed a new Crystal growth method without the use of precious metal crucibles, the Oxide Crystal growth from Cold Crucible method, OCCC). A Gallium Oxide crystal with a maximum diameter of about 5 cm has been successfully cultivated.

According to the project's researchers, "The traditional crystal growth method, which uses the precious metal iridium as a holding crucible, has problems: (1) it is difficult to reduce the cost of crystal growth; (2) Oxygen defect will occur during the manufacturing process. According to the technical economic results released in 2019, the cost of iridium is the main factor determining the total cost of Ga2O3 crystal growth. EFG method and CZ method are widely used as the mainstream Gallium Oxide crystal growth methods, but both of them require the use of iridium crucible. And since this method does not involve the oxidation of iridium, there is no limit to the gas during growth. The melt can maintain an arbitrary oxygen concentration in the growing atmosphere, which is expected to significantly control the oxygen defect of the crystals during growth. With the crucible free method and technology development, production efficiency can be further improved, resulting in crystals of large size and high quality. In this development, we have successfully produced high quality Gallium Oxide crystals without the use of precious metal crucibles through the development of C&A's original equipment based on the skull melting method." This result enables low-cost production of Gallium Oxide substrates, contributing to the realization of low-loss Gallium Oxide power semiconductors.

Innovative method: cold crucible drawing method

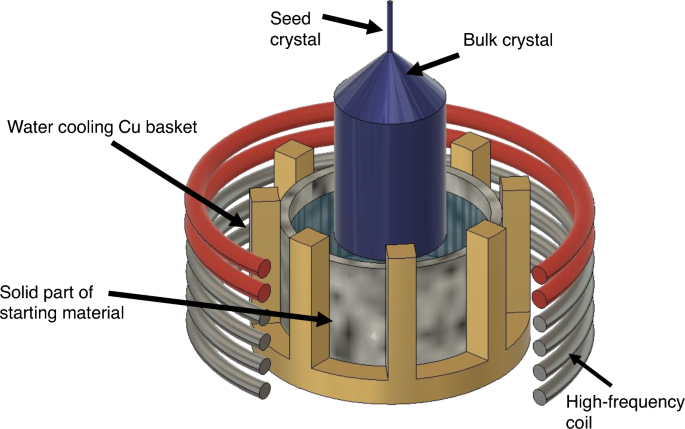

The research team developed a crystal growth method based on a cold crucible. During this process, the β-Ga₂O₃ crystals grow from the melt, which is maintained by a high-frequency induction heating system in the cold crucible. The following are the characteristics and introduction of the crystal formation method:

1、Materials and Equipment

Use a β-Ga₂O₃ powder of 99.99% purity as your starting material. The experiment was carried out in a normal air atmosphere with a flow rate of 5-10 L/min, while pure oxygen and carbon dioxide atmospheres were also tried for growth, but normal air was the best.

2、Cold Crucible Design

The cold crucible is made of copper, the size is 85 mm x 60 mm, and the top is insulated with yttrium-stabilized zirconia. The high frequency induction heating system uses SiC MOSFET transistors and DC conversion technology to control melt temperature and crystal diameter.

3、Grow Crystals

Stabilize crystal growth by adjusting the power and frequency of the generator and controlling the volume and temperature of the melt.

The experiment set the growth rate at 3-5 mm/h and the rotation speed at 4-6 rpm to ensure the uniform growth of the crystal.

The β-Ga₂O₃ crystal, which was grown in the floating zone method in the past, was used as the seed crystal to grow along the (010) direction.

4、Control and Optimize

In the process of growth, the frequency is automatically adjusted by the frequency controller to keep the phase difference of voltage and current stable to achieve stable control of melt temperature. Air flow and cooling fans are used to adjust the melt surface temperature to further optimize the diameter control of the crystal.

Schematic of the experimental setup, showing the high-frequency coil, water-cooled copper basket, sintered melt retention (cold crucible) area, and melt area.

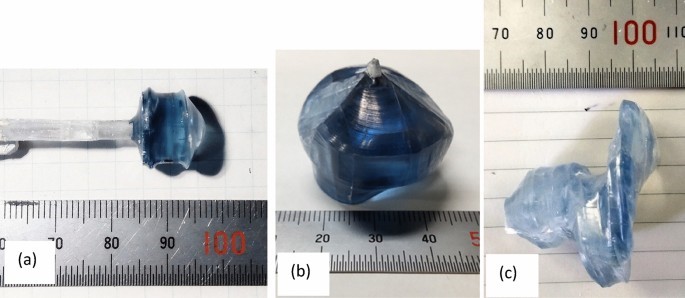

Photographs of β-Ga2O3 single crystals grown using a 5 MHz generator. (a) β-Ga2O3 single crystal with seed crystal. The size is ~ 10 mm in diameter and ~ 10 mm in body length. (b) β-Ga2O3 single crystal. The size is ~ 1 inch in diameter and ~ 15 mm in body length. (c) β-Ga2O3 single crystal with spiral growth.

Research Results and Applications

The study shows that high quality β-Ga₂O₃ crystals can be successfully grown by cold crucible drawing method. This method not only reduces the production cost, but also improves the production efficiency. Due to its excellent electrical and optical properties, β-Ga₂O₃ crystals have a wide application prospect in power electronic devices, high power lasers and ultraviolet detectors.

The researchers believe that this new method will promote the large-scale production of high-quality semiconductor materials, providing strong support for the development of electronic devices and energy systems.

Related content to the “Growth of bulk beta -Ga2O3 crystals from melt without precious-metal crucible by pulling from a cold container” appeared as the title in Scientific Reports of Nature publication.

If you want to know more content and detail, please refer to the original paper: https://doi.org/10.1038/s41598-024-65420-7