【International Papers】Understanding Dislocation and Deformation Structure In Monoclinic Ultrawide Bandgap Semiconductor β-Ga₂O₃ Under High-Stress

日期:2024-08-23阅读:656

Researchers from The Pennsylvania State University have published a dissertation titled "Understanding Dislocation and Deformation Structure In Monoclinic Ultrawide Bandgap Semiconductor β-Ga2O3 Under High-Stress" in Microscopy and Microanalysis.

Abstract

Beta gallium oxide (β-Ga2O3) is an ultrawide bandgap semiconductor that is of interest due to its 4.8 eV band gap, tunable carrier concentration, and low-cost native substrates with relatively low defect densities [1]. Demonstrating tolerance to ionizing radiation and an 8 MV/cm theoretical breakdown field, its properties indicate promise in optoelectronics and power electronics, especially in operation under extreme environments [2]. Device failure in high power electronics typically can occur due to pre-existing defects in the crystals which are exacerbated while under extreme environments, i.e., high temperature and electric potential. Thus, a detailed knowledge of β-Ga2O3’s defect structure is the key to incorporate it into industrial use. Scanning/transmission electron microscopy (S/TEM) has been applied to the atomic-scale study of β-Ga2O3, for example identifying defective γ-Ga2O3 phase inclusions, the coordination of aluminum interstitial atoms near a β-Ga2O3/β-(Al0.2Ga0.8)2O3 interface, band gap variation across heterostructures, and the formation of divacancy-interstitial complexes [3-7]. Study of β-Ga2O3’s dislocations, however, has been limited and focuses on formation mechanisms during growth [8]. As attempts to scale up epitaxial wafer growth continue, knowledge of dislocations is vital. These are often referred to as “device-killing” defects in silicon carbide and gallium nitride. Recently, dislocation glide and dislocation bundles in β-Ga2O3 with a Burgers vector of b || [010] were observed in a Schottky barrier diode using synchrotron X-ray topography [9]. This technique was also previously used to study dislocations in a β-Ga2O3 single crystal (010)-oriented sample [10]. However, these did not examine the impact of failure on the dislocation structure, nor provide the direct defect visualization S/TEM is capable of.

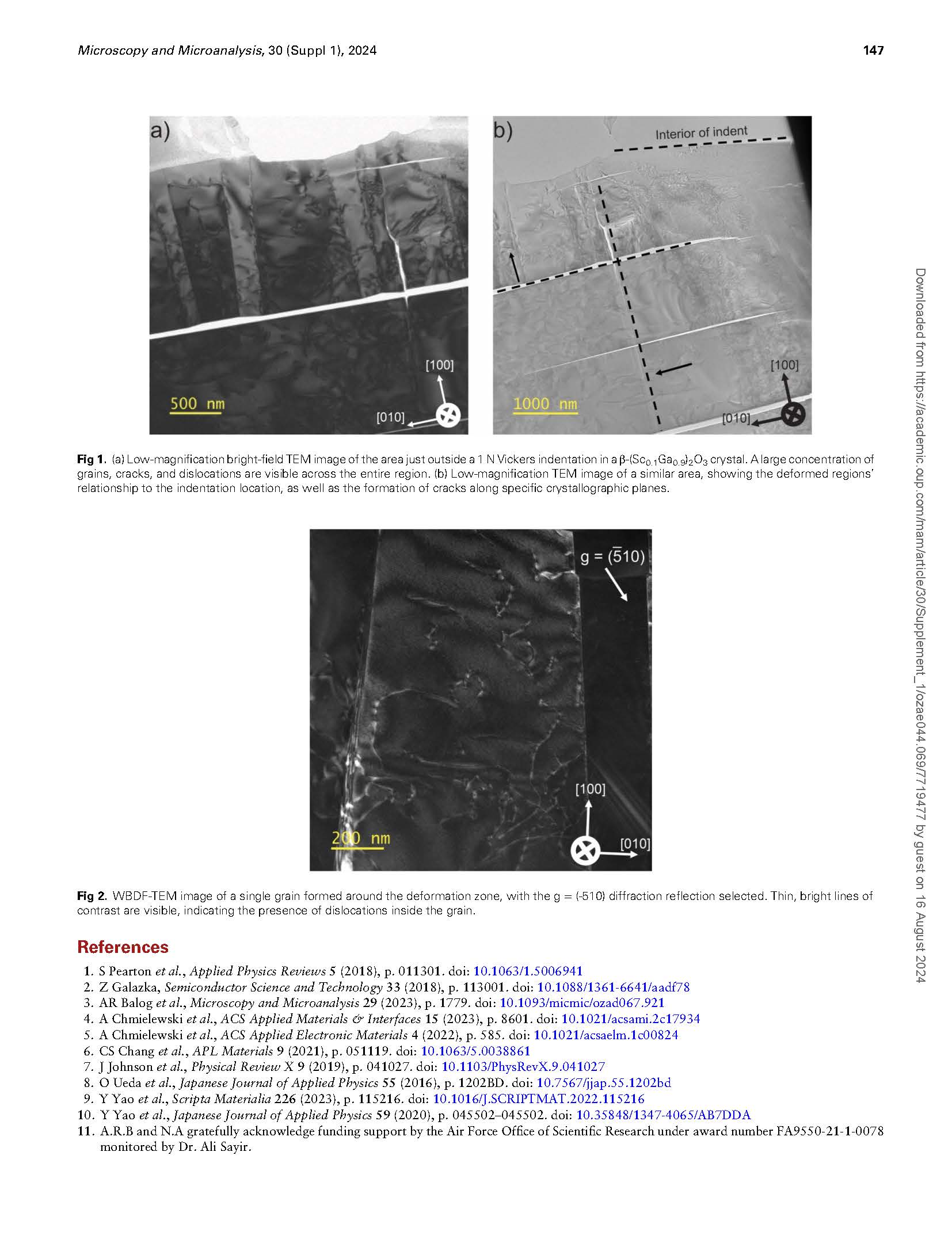

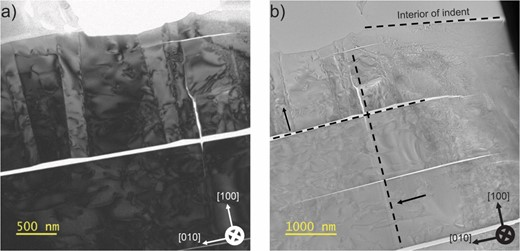

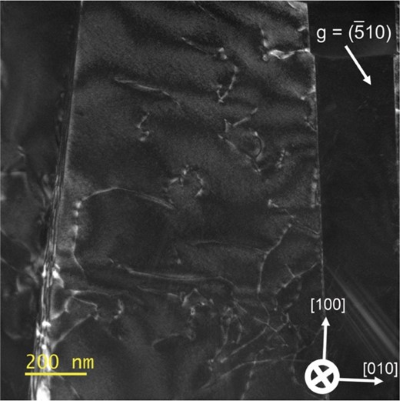

In this work, we study the dislocation and deformation behavior in (100)-oriented single crystals of β-Ga2O3 after a 1 N Vickers indentation. From our prior studies, it was initially hypothesized that some type of stress may be responsible for the formation of γ-Ga2O3 on the surface of β-Ga2O3 melt-grown single crystals [3]. To test this, 1 N Vickers indentations were performed on the β-Ga2O3 samples. While no evidence of γ-Ga2O3 formation is observed, dislocations are nucleated under extreme stress. Under such an intense force, the material forms a network of grains and cracks along certain crystallographic directions, with dislocations extending throughout the grains and appearing to emanate from grain boundaries (Figure 1a and 1b). Weak-beam dark-field TEM (WBDF) was performed to better understand the dislocation structure due to its ability to visualize crystal defects with a higher diffraction contrast (Figure 2). Through different imaging conditions, we further identify the Burgers vector for the existing dislocations. This work will provide a comprehensive examination of dislocation and deformation structure as well as dislocation dynamics in β-Ga2O3 via TEM, enabling new understanding of its slip system and deformation processes [11].

Fig 1.(a) Low-magnification bright-field TEM image of the area just outside a 1 N Vickers indentation in a β-(Sc0.1Ga0.9)2O3 crystal. A large concentration of grains, cracks, and dislocations are visible across the entire region. (b) Low-magnification TEM image of a similar area, showing the deformed regions’ relationship to the indentation location, as well as the formation of cracks along specific crystallographic planes.

Fig 2.WBDF-TEM image of a single grain formed around the deformation zone, with the g = (-510) diffraction reflection selected. Thin, bright lines of contrast are visible, indicating the presence of dislocations inside the grain.

DOI:doi.org/10.1093/mam/ozae044.069