【World Express】Why Gallium Oxide Can Help Deliver A Sustainable AI Future

日期:2024-09-20阅读:928

We've all seen the headlines: Data centers are projected to consume 6% of U.S. energy by 2026—with that number climbing as high as 32% in other places, such as Ireland.

If things don't change, this might be a significant underestimation. AI is driving exponential growth in the need for computing power. Microsoft, for instance, is reportedly planning to spend over $50 billion annually on data centers.

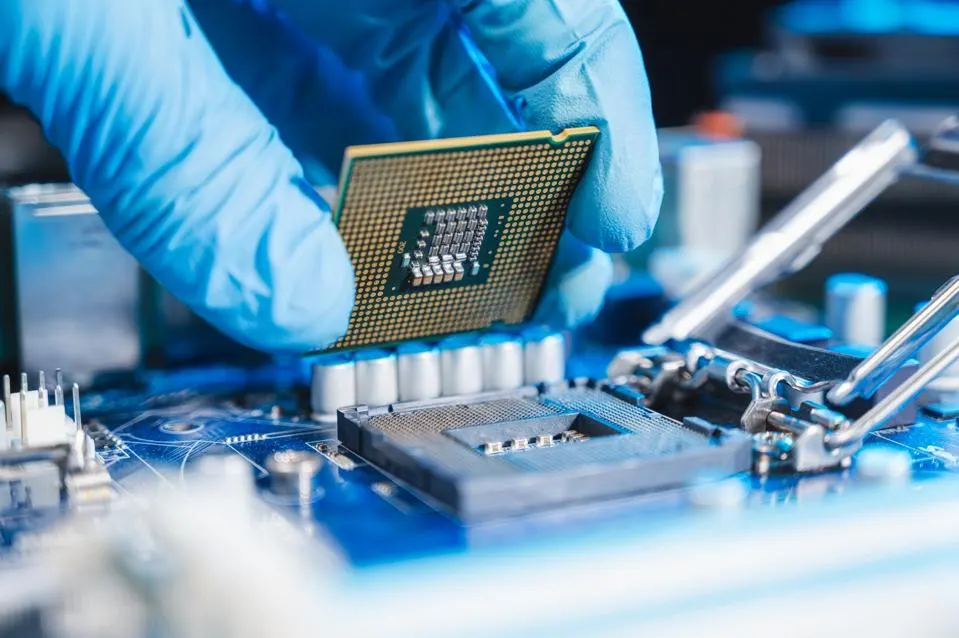

While silicon has long been the cornerstone of the semiconductor industry, its inefficiencies can lead to energy losses, so the industry has been searching for ways to reduce excess power consumption and unnecessary heat generation. Gallium oxide holds the potential to mitigate these inefficiencies.

The Potential Of Gallium Oxide

Gallium oxide has long been of interest in the semiconductor space. Researchers understood it could be a potential replacement for silicon components due to its conductive properties but could not figure out how to cost-effectively produce gallium oxide chips at scale.

Advances in AI have given new process control tools to make industrial manufacturing production lines more efficient. These tools can bring down costs and—as a result—unlock the ability to produce gallium oxide-based chips and hardware at scale.

Gallium oxide-based chips are five times more conductive than their silicon counterparts, offering numerous advantages:

1.Reduced Energy Losses: Gallium oxide's higher conductivity means that data centers can operate with significantly lower energy wastage.

2.Higher-Voltage Operation: The material can handle higher voltages, making it ideal for the demanding environments of modern data centers.

3.Higher-Temperature Operation: Gallium oxide components can operate efficiently at higher temperatures, reducing the need for extensive cooling systems.

4.Higher-Frequency Operation: This enables faster data processing and transmission, crucial for AI and other advanced computing applications.

Because of this, data centers utilizing gallium oxide components can operate with considerably less energy consumption when compared to traditional silicon-based centers.

Breaking Down Barriers

The NICT (National Institute of Information and Communications Technology) in Japan has been at the forefront of gallium oxide research. They've successfully developed high-voltage gallium oxide power devices, demonstrating the material's potential for high-power applications.

Another key player is Novel Crystal Technology Inc., a spin-off company from Tamura Corporation. They've been working on mass-producing high-quality gallium oxide substrates, which are crucial for the widespread adoption of this technology.

In the U.S., researchers at the University at Buffalo and Rensselaer Polytechnic Institute have been collaborating on developing gallium oxide-based electronic devices, focusing on improving the material's performance and reliability.

Despite the promising advancements, there are still several challenges that need to be addressed before gallium oxide can fully realize its potential:

1.Material Defects: Gallium oxide crystals can contain defects that affect device performance. Researchers are working on improving crystal growth techniques to minimize these defects.

2.Device Reliability:The long-term reliability of gallium oxide devices under high-voltage and high-temperature conditions is still being studied. More research is needed to ensure these devices can withstand prolonged use in demanding environments.

3.Thermal Management:While gallium oxide can operate at higher temperatures than silicon, its thermal conductivity is actually lower. This presents challenges in heat dissipation, especially for high-power applications.

4.Doping Limitations:P-type doping of gallium oxide has proven to be difficult, limiting the types of devices that can be created. This is a significant drawback compared to silicon, which can be easily doped both n-type and p-type.

5.Cost: Although production costs are decreasing, gallium oxide devices are still more expensive to produce than their silicon counterparts. Achieving cost parity or advantage will be crucial for widespread adoption.

Also, while gallium oxide shows promise in certain applications, it may not be a universal replacement for silicon. Silicon's versatility and the vast infrastructure built around its production and use mean that it will likely continue to dominate many areas of the semiconductor industry for the foreseeable future.

Moreover, other wide-bandgap semiconductors like silicon carbide (SiC) and gallium nitride (GaN) are also competing in the high-power, high-frequency space. Each material has its strengths and weaknesses, and the best choice often depends on the specific application.

A Vision For A Sustainable AI Future

Moving forward, it's clear that gallium oxide has the potential to play a significant role in next-generation electronics, particularly in high-power and high-frequency applications.

However, overcoming the existing challenges will require continued research, development and collaboration. The future of gallium oxide in electronics is promising, but it's important to approach it with a balanced perspective, acknowledging both its potential and its current limitations.

Despite the data center doom-and-gloom that permeates discourse about the sustainability of AI, I’m hopeful. New raw materials and new manufacturing processes may be on the precipice of unlocking and unblocking supply chain challenges across the AI sector. More importantly, these developments mean our world's energy security doesn’t need to be sacrificed to realize an AI future.

The transition from silicon to gallium oxide represents a critical shift in how we manage the increasing energy demands of data centers. By embracing this new material, our AI-driven future has the potential to be both powerful and sustainable, with the integration of gallium oxide into data centers offering a potential paradigm shift.

Matthew Putman, co-founder and CEO of Nanotronics, an AI-driven manufacturing company serving top semiconductor manufacturers.